Central pipe throwing-rinsing washing method and washing machine manufactured by the same

A central tube and washing machine technology, applied in the field of washing machines, can solve the problems of small power consumption, large water consumption, wear and tear of clothes, etc., and achieve the effect of reducing power consumption, reducing water consumption, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

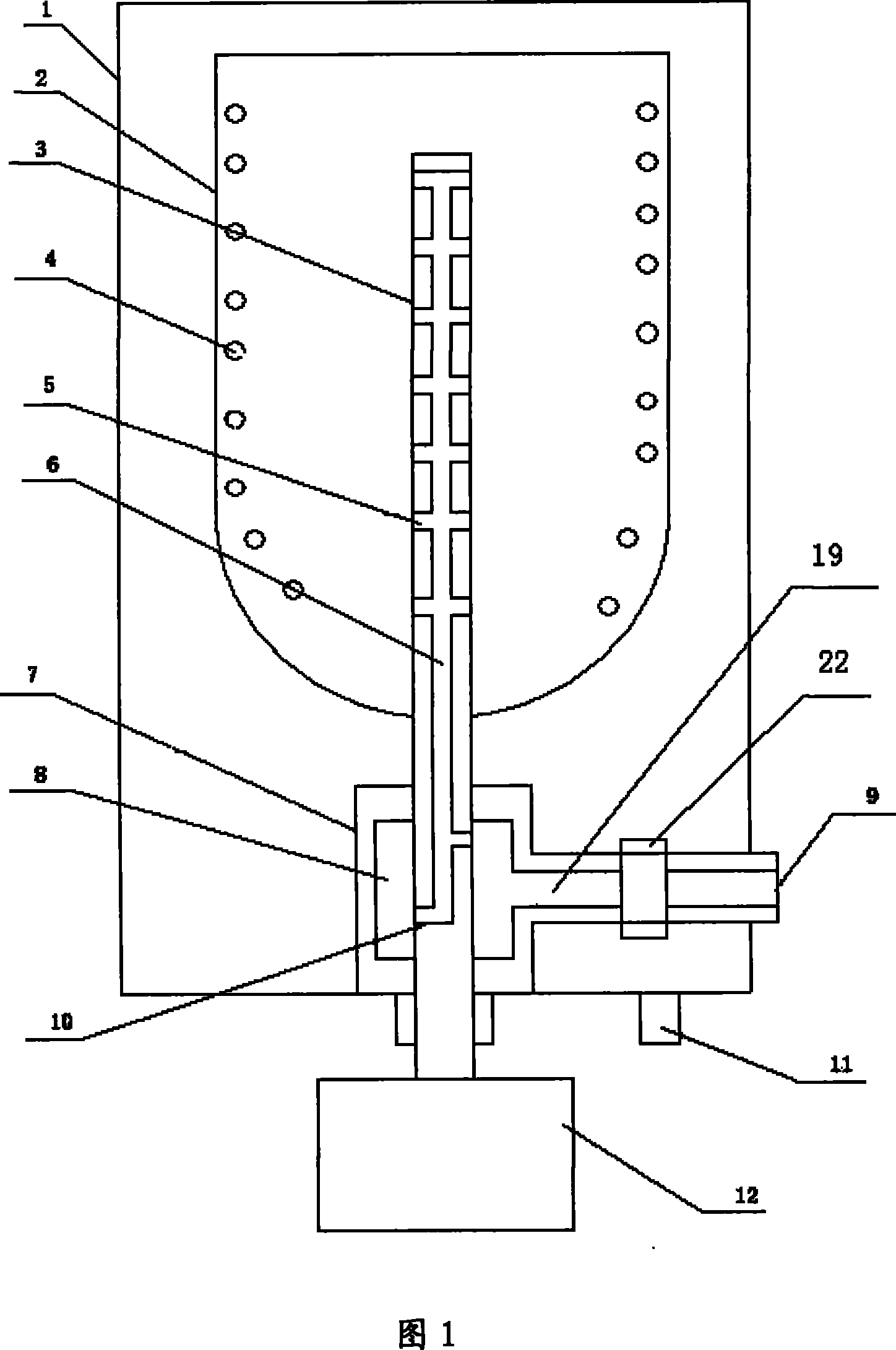

[0020] A semi-automatic pulsator-type bottom water-filling washing machine, which applies the central tube rinsing and bleaching laundry technology to the semi-automatic pulsator-type washing machine, specifically, the central tube 3, the water outlet hole 5, the central axis channel 6, the sealing device 7, and the water inlet pipe 9 , the through hole 10 and the drain 11 are arranged in the dehydration barrel according to the shown in Fig. There is a sealing chamber 8, and a central axis channel 6 is provided in the central tube 3, and the central axis channel 6 leads to the position of the sealing cavity 8, and a through hole 10 is provided between the central axis channel 6 and the sealing cavity 8, and the sealing cavity cavity An outward port 19 is provided to connect the water inlet pipe 9. The motor 12, the V-belt and the transmission device 13 provide the power device for the washing machine.

[0021] After the clothes are washed in the washing tub of the washing mach...

Embodiment 2

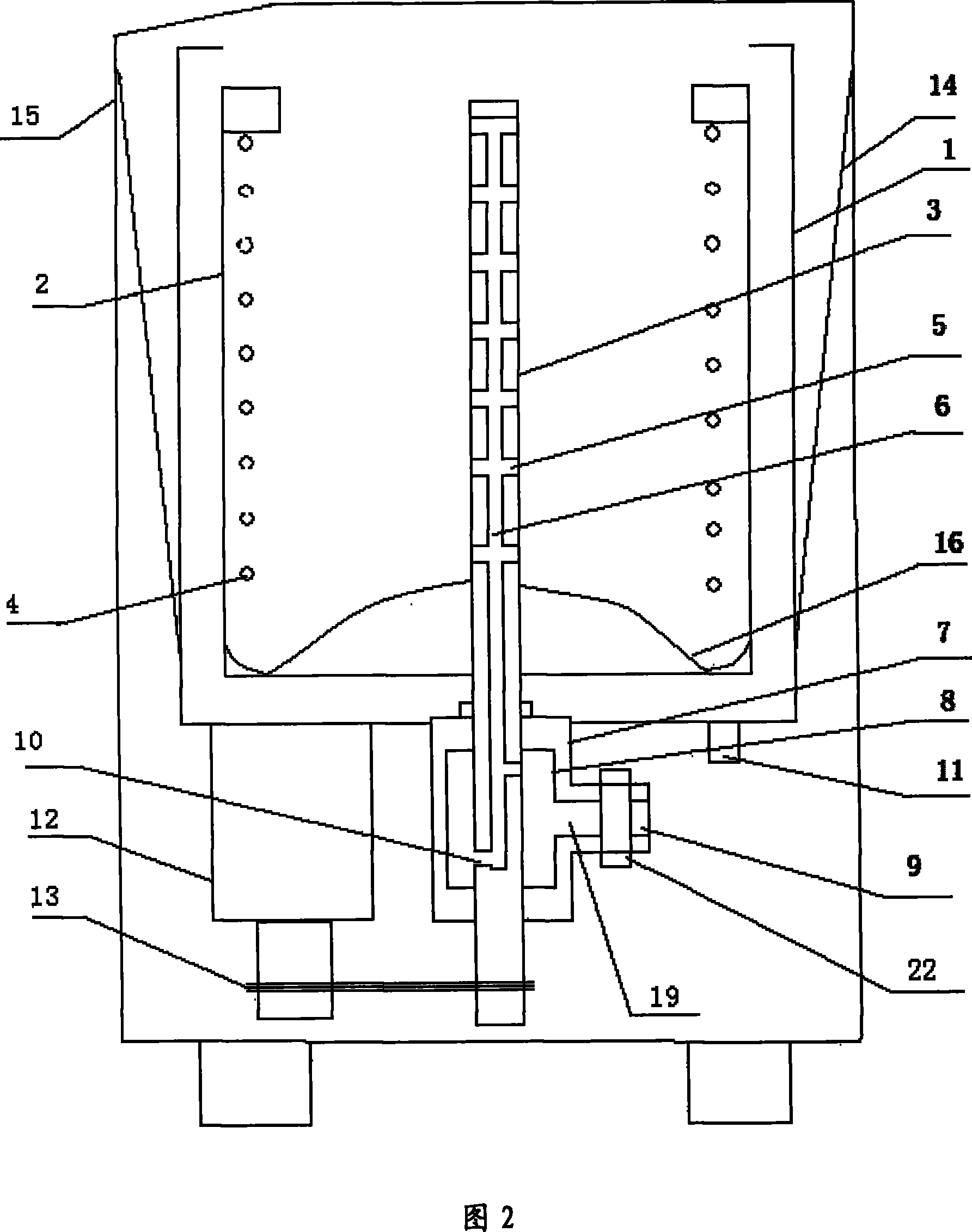

[0026] A fully automatic pulsator type bottom water-filling washing machine, which applies the central tube drifting technology to the fully automatic pulsator type washing machine, specifically, the central tube 3 is arranged in the dehydration bucket as shown in Figure 2, and the central tube 3 is connected with the dehydration The axis of the pulsator at the bottom of the barrel body is fixed as a whole, and a water outlet 5 is provided on the central tube 3; a sealing chamber 8 is provided in the sealing device 7, and a central axis channel 6 is provided in the central tube 3, and the central axis channel 6 Down to the position of the sealing chamber 8, a through hole 10 is provided between the central shaft passage 6 and the sealing chamber 8, and the sealing chamber body is provided with an outward opening 19, which is connected to the water inlet pipe 9, the motor 12, the V-belt and the transmission device 13 provides a power unit for the washing machine.

[0027] Since...

Embodiment 3

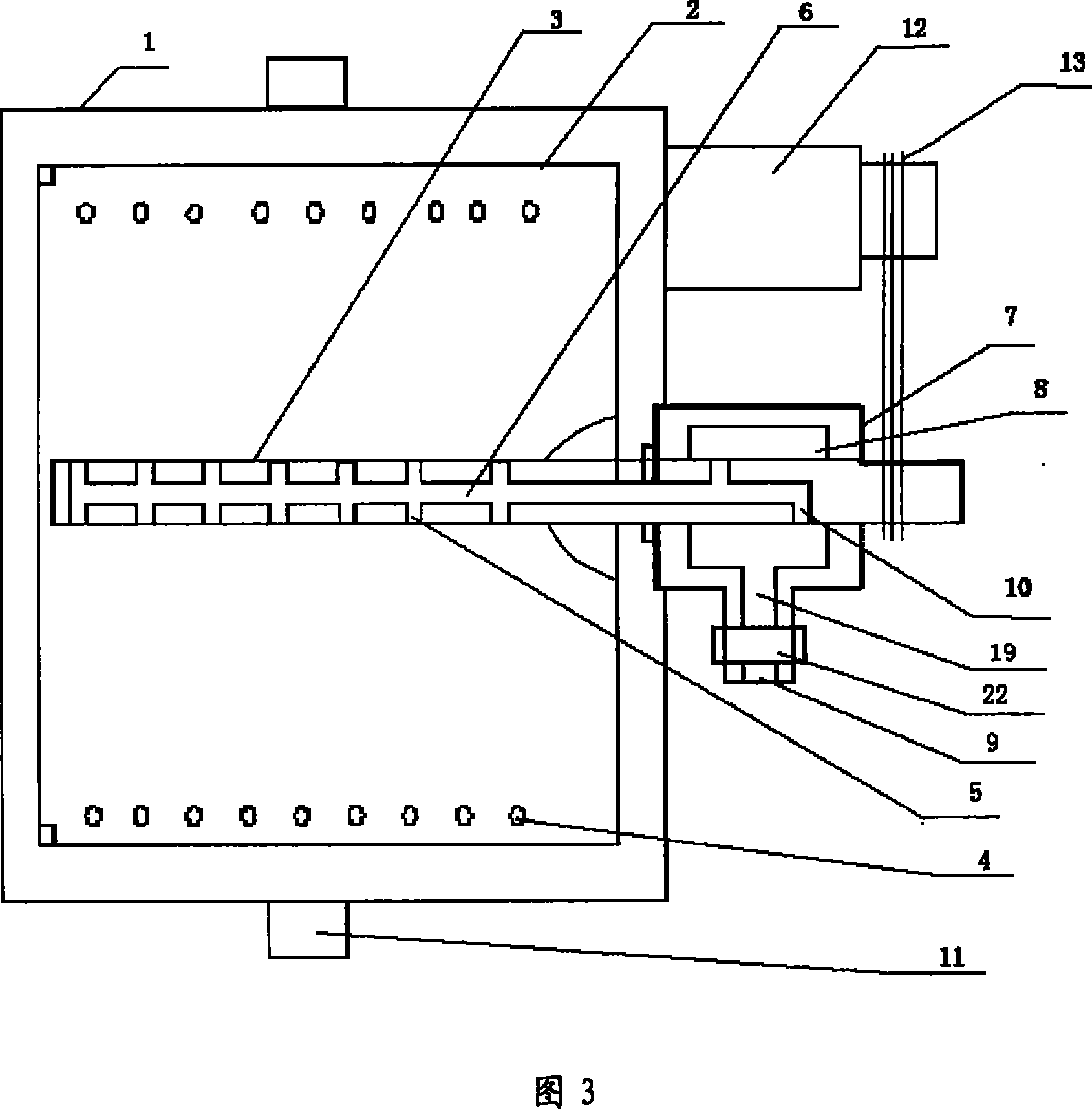

[0033] A drum-type rear-end water-filling washing machine, which applies the central tube spin-and-bleach washing technology to the drum-type washing machine, specifically, the central tube 3 is arranged in the dehydration bucket as shown in Figure 3, and the central tube 3 is connected to the dehydration bucket body. The shaft center of the end is fixed as one, and the central tube 3 is provided with a water outlet hole 5; a sealing chamber 8 is provided in the sealing device 7, and a central axis channel 6 is provided in the central tube 3, and the central axis channel 6 leads to the sealing cavity 8 position, a through hole 10 is provided between the central axis channel 6 and the sealing chamber 8, and the sealing chamber cavity is provided with an outward port 19, which is connected to the water inlet pipe 9. The motor 12, the V-belt and the transmission device 13 provide power for the washing machine .

[0034] Since the washing bucket and the dehydration bucket of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com