High speed chief axis on-line dynamic poise device

A high-speed spindle and spindle technology, applied in static/dynamic balance testing, measuring devices, instruments, etc., to achieve the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

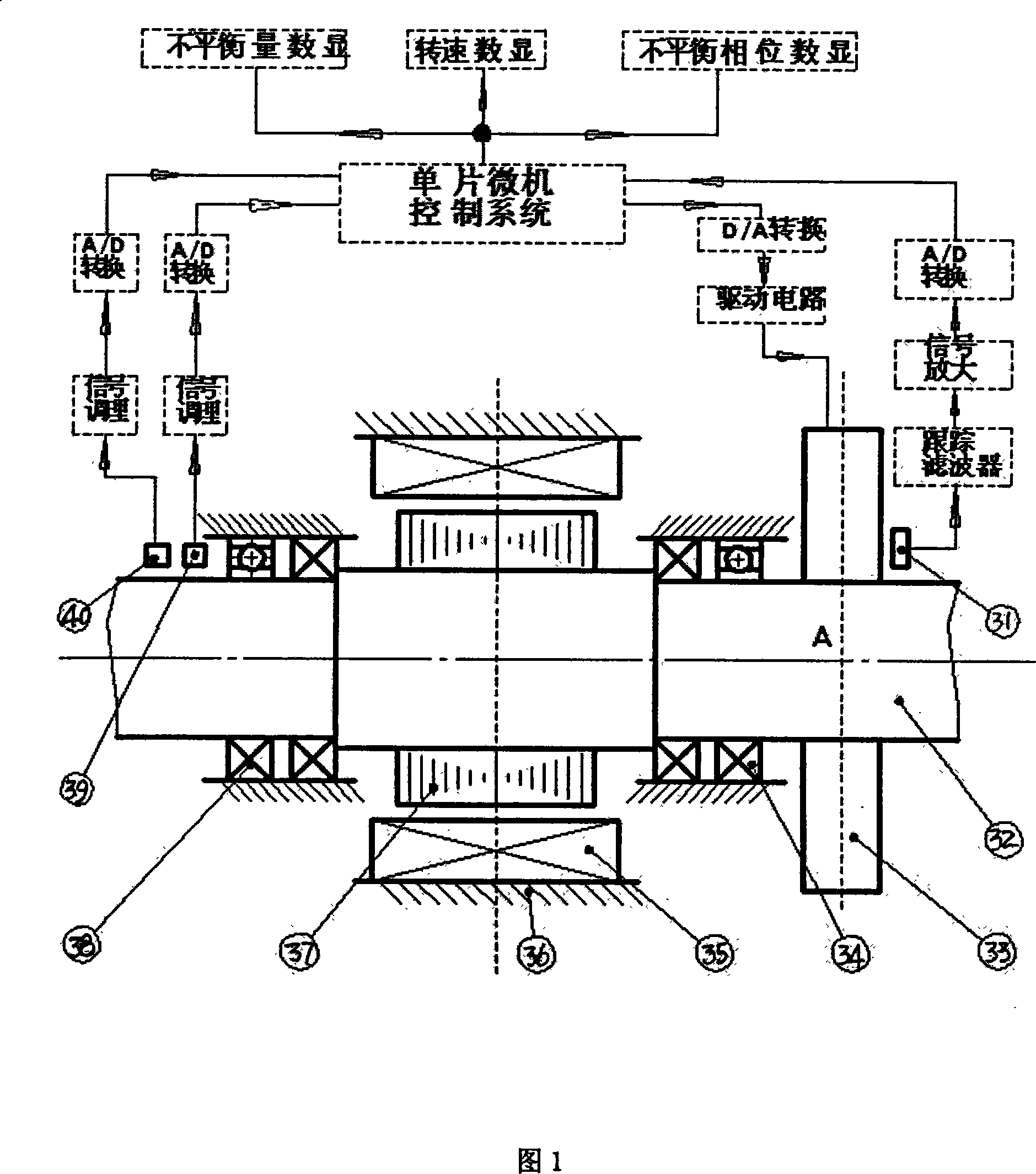

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

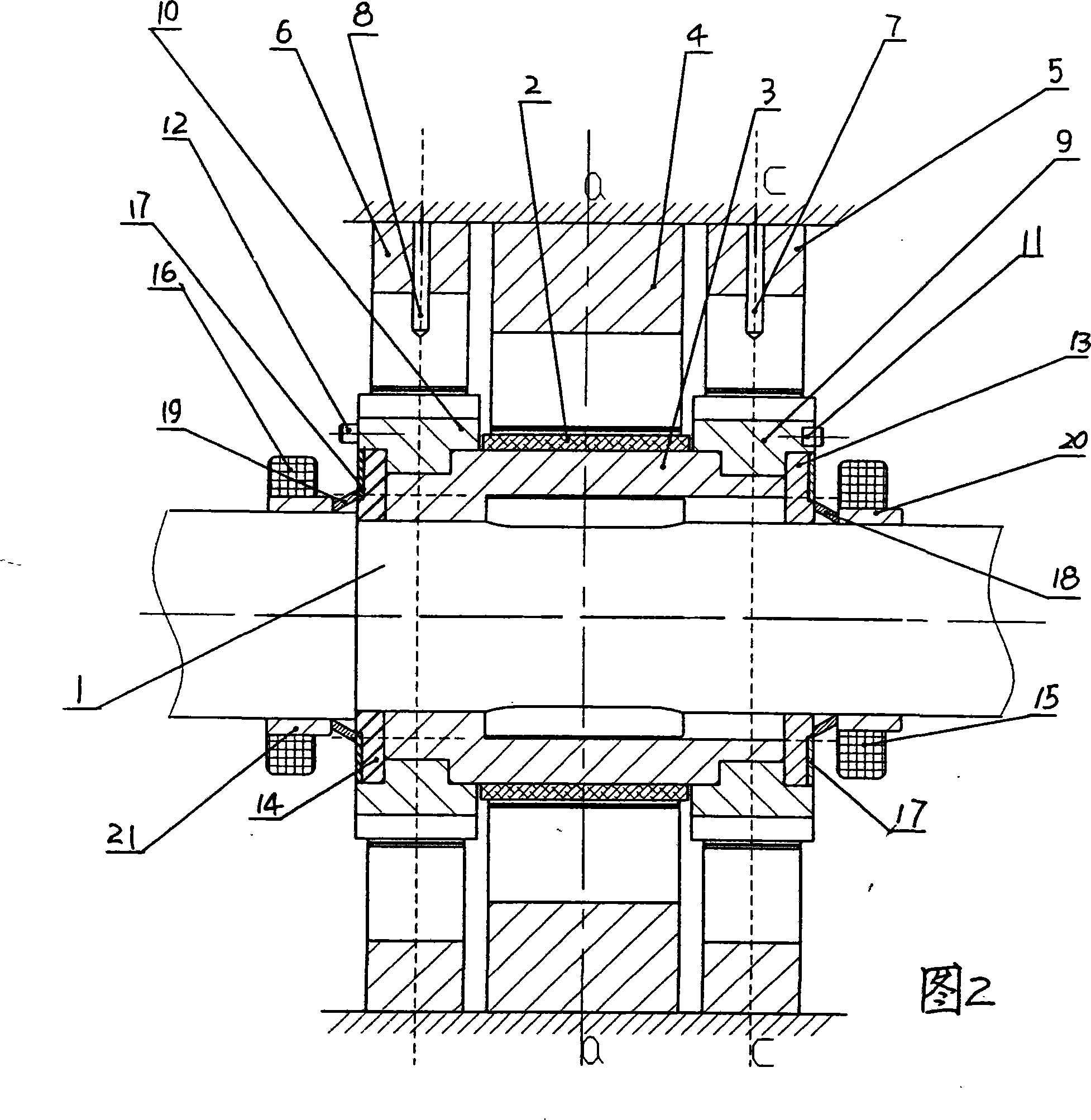

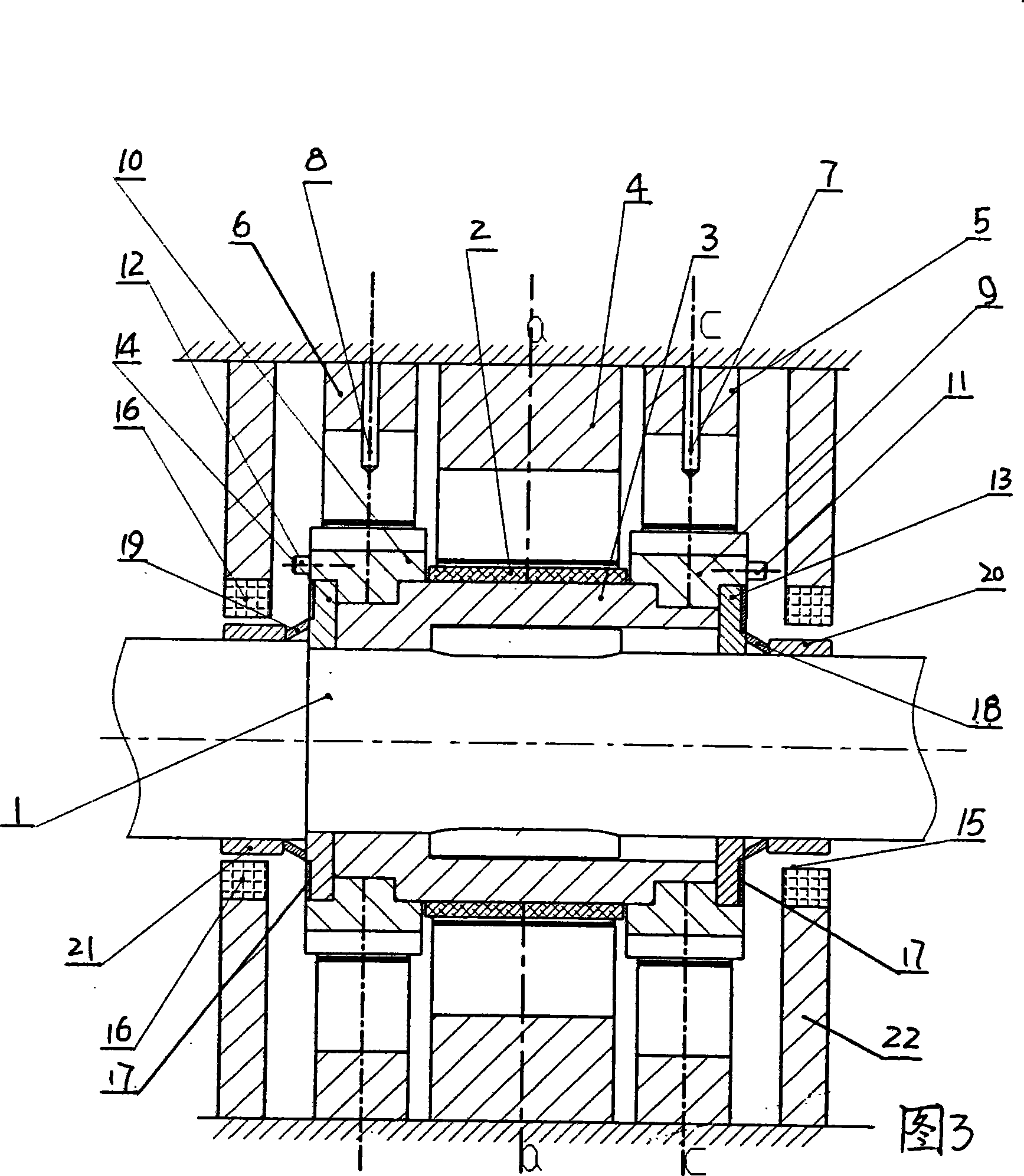

[0014] A high-speed spindle online dynamic balancing device, including an indirect online dynamic balancing device that includes a slide plate seat 3 fixed to the spindle 1 and provided with a ferromagnetic material layer 2 on its middle peripheral surface, and a stator 4 slotted along the circumference and embedded with control windings in the groove The mechanism also includes stators 5 and 6 which are located on both sides of the indirect online dynamic balance mechanism and have grooves along the circumference and embedded with control windings in the grooves, and sensors 7 and 8 fixed on the stators. The sliding plate 9, 10, the balance mass 11, 12 fixed on the sliding plate 9, 10, the pressure plate 13, 14 sleeved on the main shaft 1 and in contact with the end surface of the sliding plate seat 3, sliding plate 9, 10 are mixed Type online dynamic balancing mechanism; electromagnetic coils 15, 16 are arranged on one side of the pressing plates 13, 14, a ferromagnetic mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com