Improved electrophoretic display and preparation method thereof

An electrophoretic display and electrophoretic technology, applied in the direction of instruments, identification devices, nonlinear optics, etc., can solve the problems of application limitations, unfavorable display energy saving, etc., and achieve the effects of improving reflectivity, optical stability, and contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Terminology Explanation:

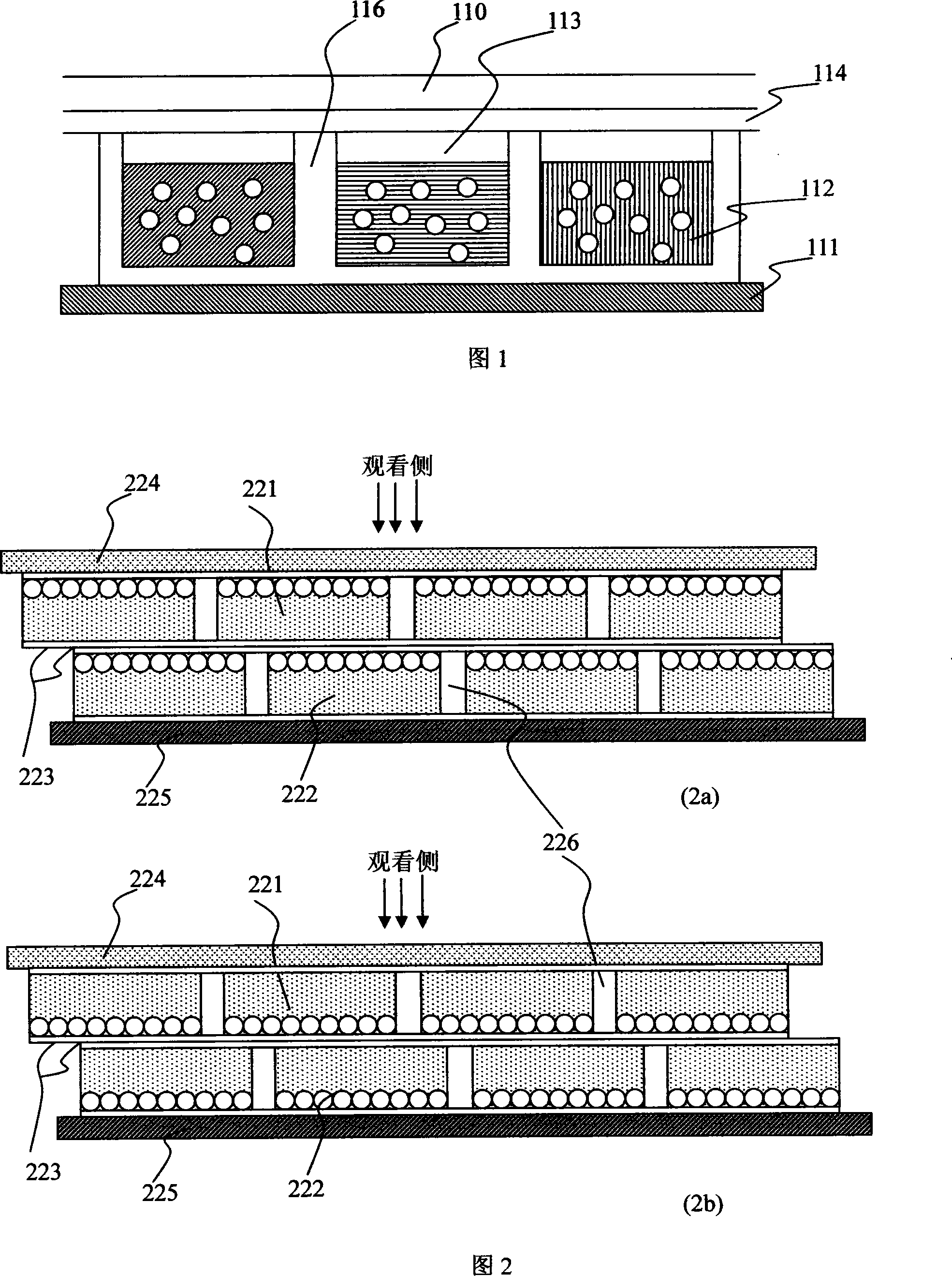

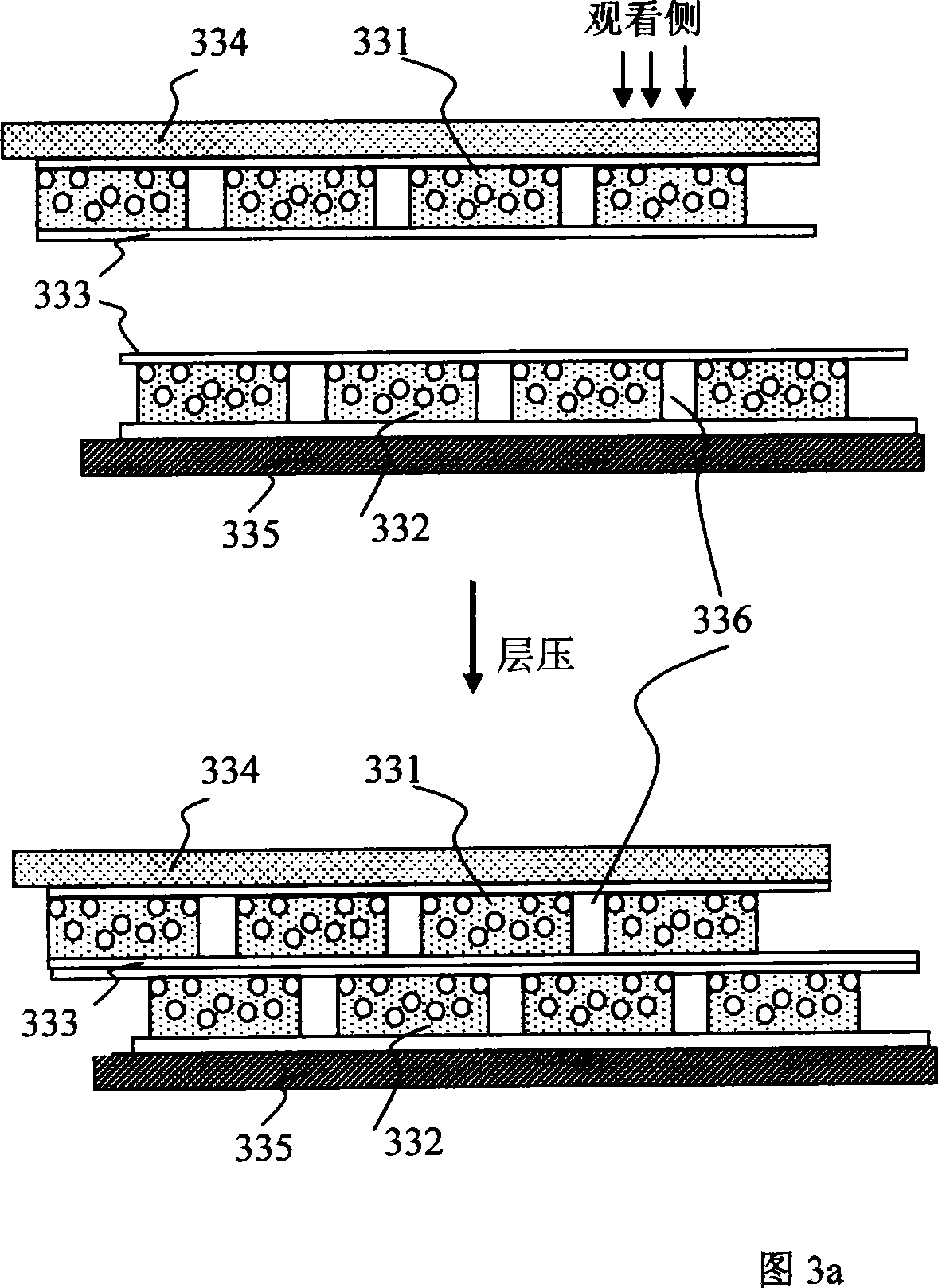

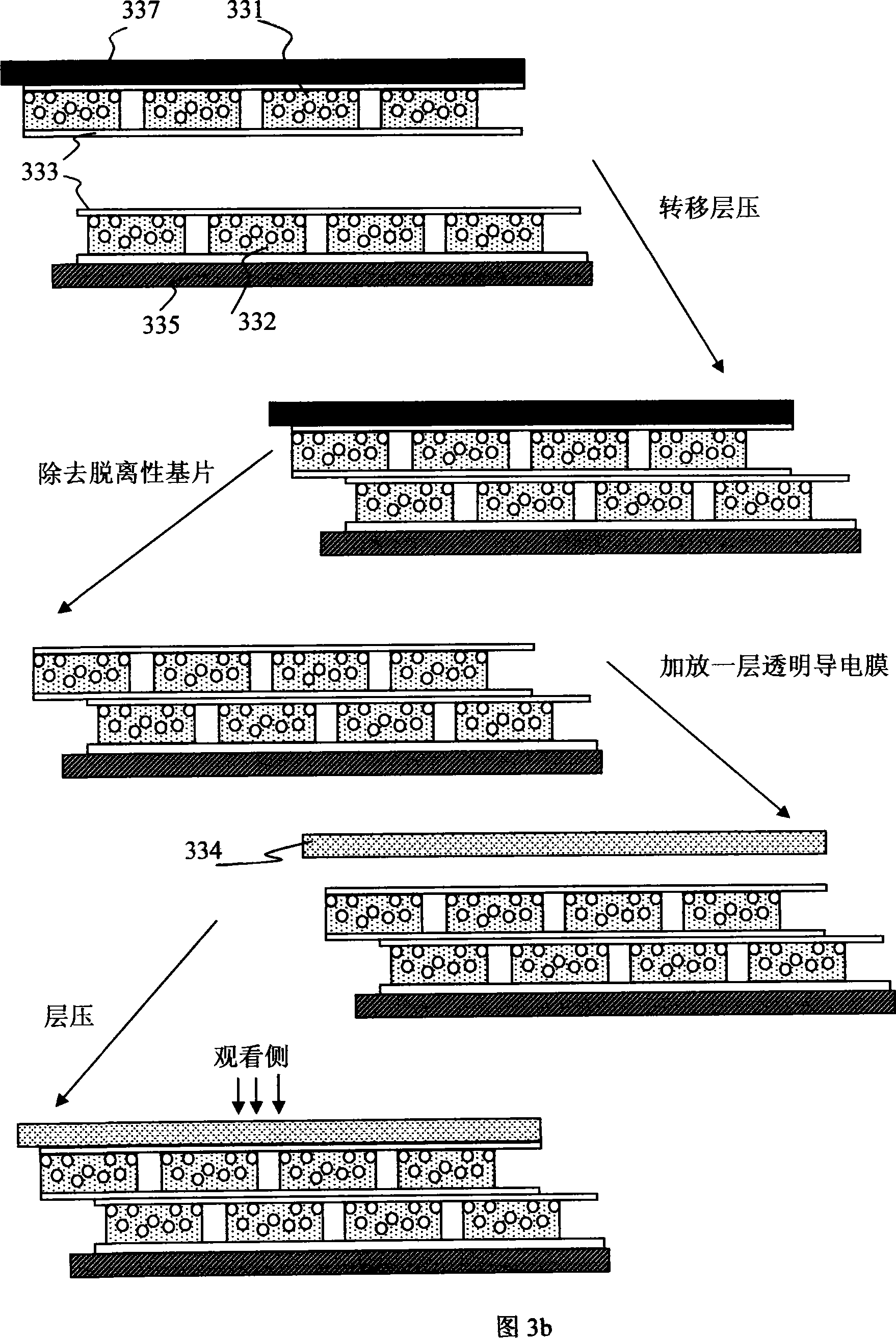

[0071] "Microcup": means a cup-shaped recess produced by micromolding or pattern exposure, having a well-defined shape, size and aspect ratio predetermined according to the specific parameters of a certain manufacturing method.

[0072] "Aspect ratio" is a general term in the field of electrophoretic displays and, for microcups, refers to the ratio of depth to width or depth to length of a cell.

[0073] "Maximum optical density (Dmax)" means the maximum optical density a display can achieve.

[0074] "Minimum optical density (Dmin)" refers to the minimum optical density at which the background appears.

[0075] "Contrast ratio" is defined as the ratio of the percent reflectance of an electrophoretic display in the state of minimum optical density to the percent reflectance of the display in the state of maximum optical density.

[0076] "Display element": the basic unit with optical switching performance, such as display boxes using microcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com