Equal circle type single-phase winding of intermediate frequency permanent magnet generator

A permanent magnet generator and single-phase winding technology, which is applied in the field of turn-type single-phase windings, can solve the problems of single-phase motor performance noise, small number of slots, and low efficiency, and achieve small magnetic potential harmonics, convenient implementation, and The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

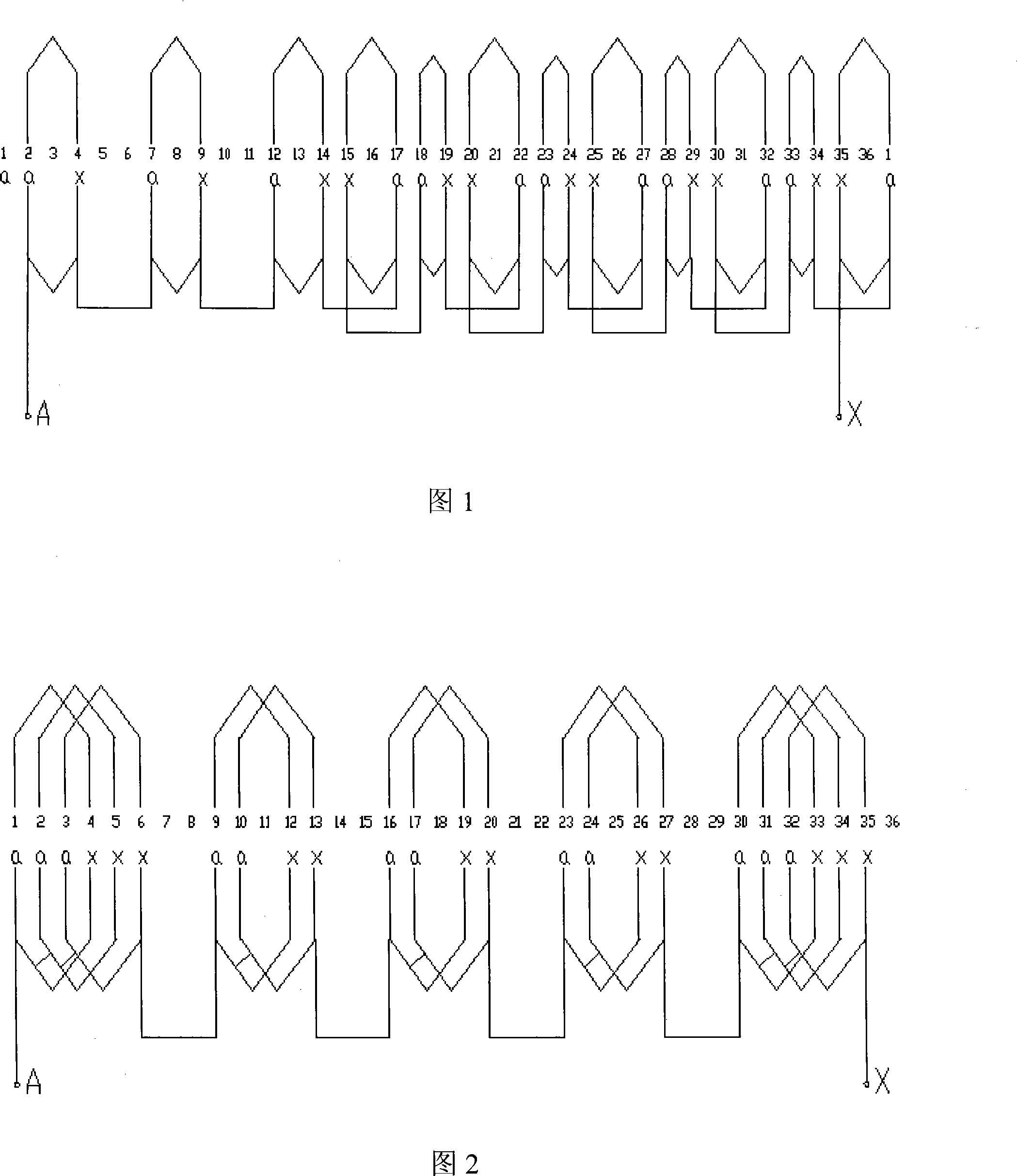

Embodiment 1

[0009] Embodiment 1: As shown in Figure 1, a Z=36, 2P=14, Y=1-3, Y=1-2, m=1 intermediate frequency permanent magnet motor single-phase winding layout single-phase winding AX, The lead-out head is marked as A and X, and it is composed of 12 equal-turn coils in series, of which there are 8 turns with pitch Y=1-3, specifically in slots 2, 4; 7, 9; 12, 14; 15, 17; 20, 22; 25, 27; 30, 32; 35, 1 sixteen grooves, pitch Y = 1-2 has 4 turns, specifically in the groove 18, 19; 23, 24; 28, 29 ; In the eight slots of 33 and 34, the single-phase windings with unequal distances and equal turns formed in this way eliminate the third harmonic magnetic potential, and the fifth and seventh harmonic magnetic potentials also greatly weaken the total harmonic magnetic potential. 1.5%, good sinusoidality. achieve the purpose of the invention.

Embodiment 2

[0010] Embodiment 2: As shown in FIG. 2 , a Z=36 2P=10 Y=1-4, m=1 medium-frequency permanent magnet motor single-phase winding layout. The single-phase winding AX, marked as A and X, is composed of 12 equally spaced and equally spaced coils in series, and the coils are at 1, 2, 3, 4, 5, 6; 9, 10, 12, 13; 17, 19, 20; 23, 24, 26, 27; 30, 31, 32, 33, 34, 35; 24 slots. The coil pitches are all Y=1-4.

[0011] The equidistant and equal-turn single-phase windings formed in this way eliminate the third harmonic magnetic potential, and greatly weaken the fifth and seventh harmonic magnetic potentials. The total harmonic magnetic potential is less than 1.5%, and the sine property is very good. achieve the purpose of the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com