Liquid-cooled battery and method for operating such a battery

A battery, liquid cooling technology, applied in secondary batteries, battery pack components, secondary battery gas removal, etc., can solve the problem of fire, explosive gas entering the battery, etc., and achieve the effect of high safety and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

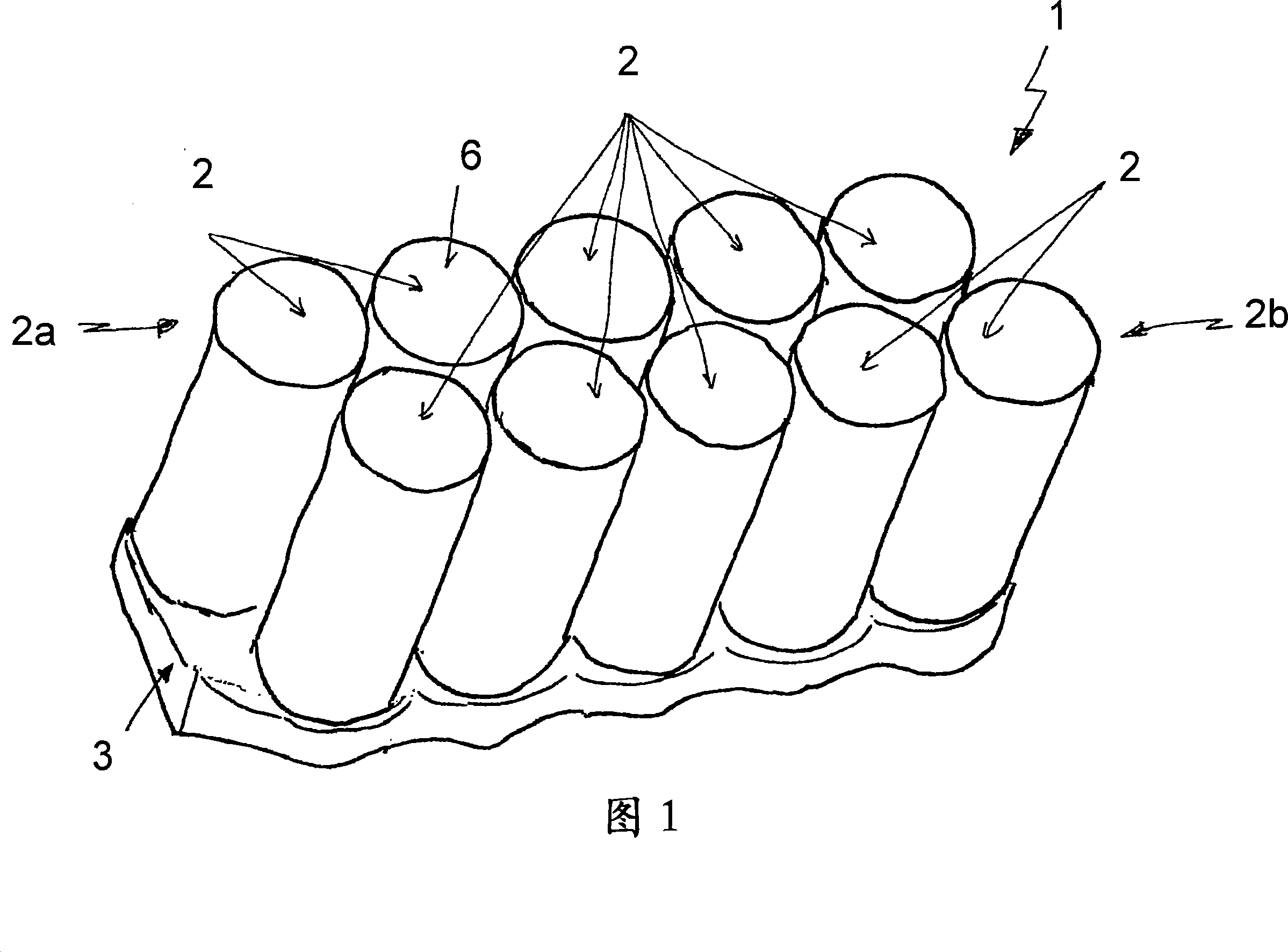

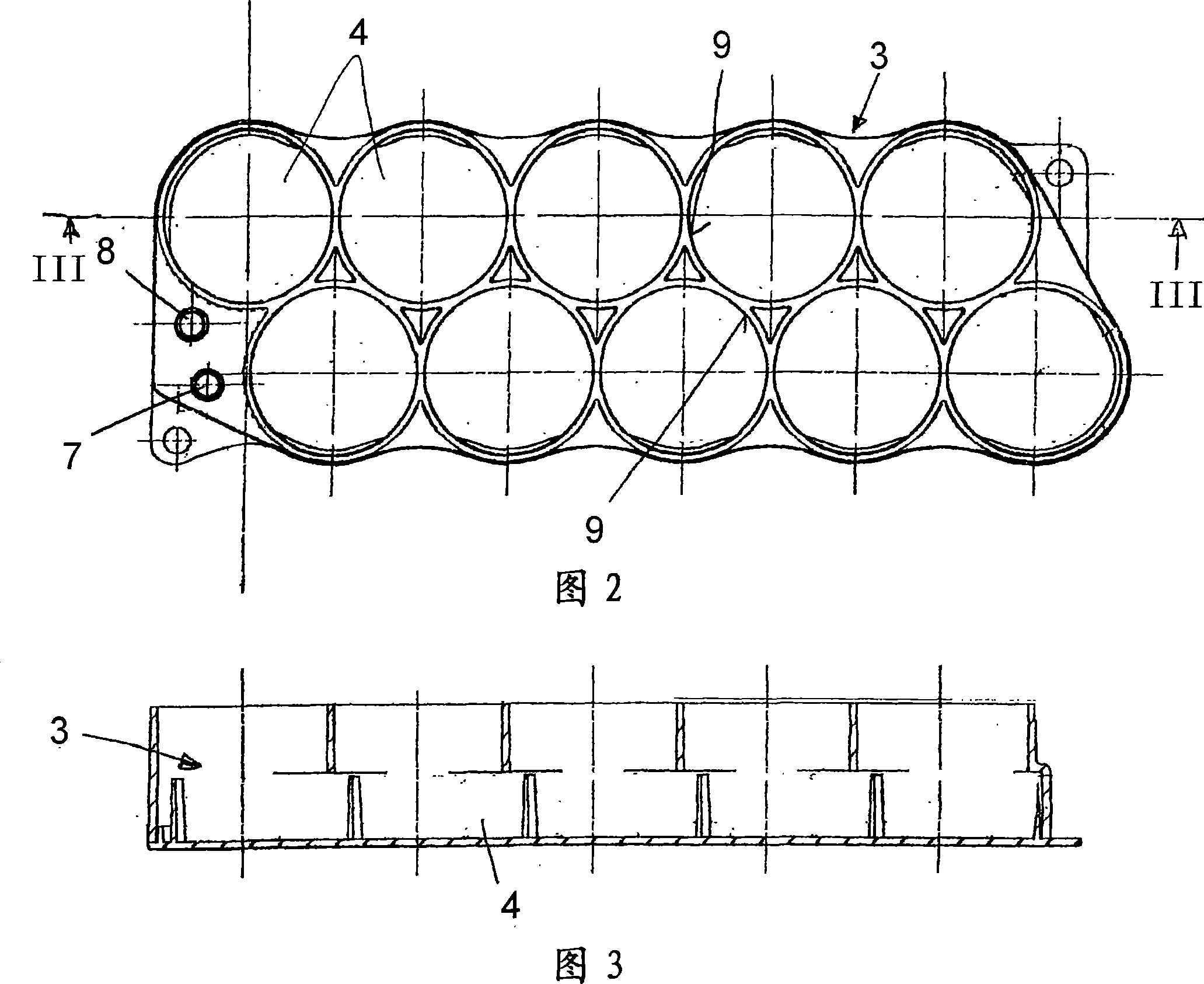

[0021] FIG. 1 schematically shows a battery 1 . The battery 1 comprises a plurality of individual energy storage cells 2 which are arranged next to each other in rows, shown by way of example in FIG. 1 as two rows 2a, 2b. The two rows 2a, 2b shown in Fig. 1 are arranged alternately so that the adjacent rows 2a, 2b are staggered relative to each other by half of the distance between the centerlines of the energy storage units 2 in a row. This allows the rows 2a, 2b to be packed very closely relative to each other. Overall, this results in a very compact construction of the battery 1 .

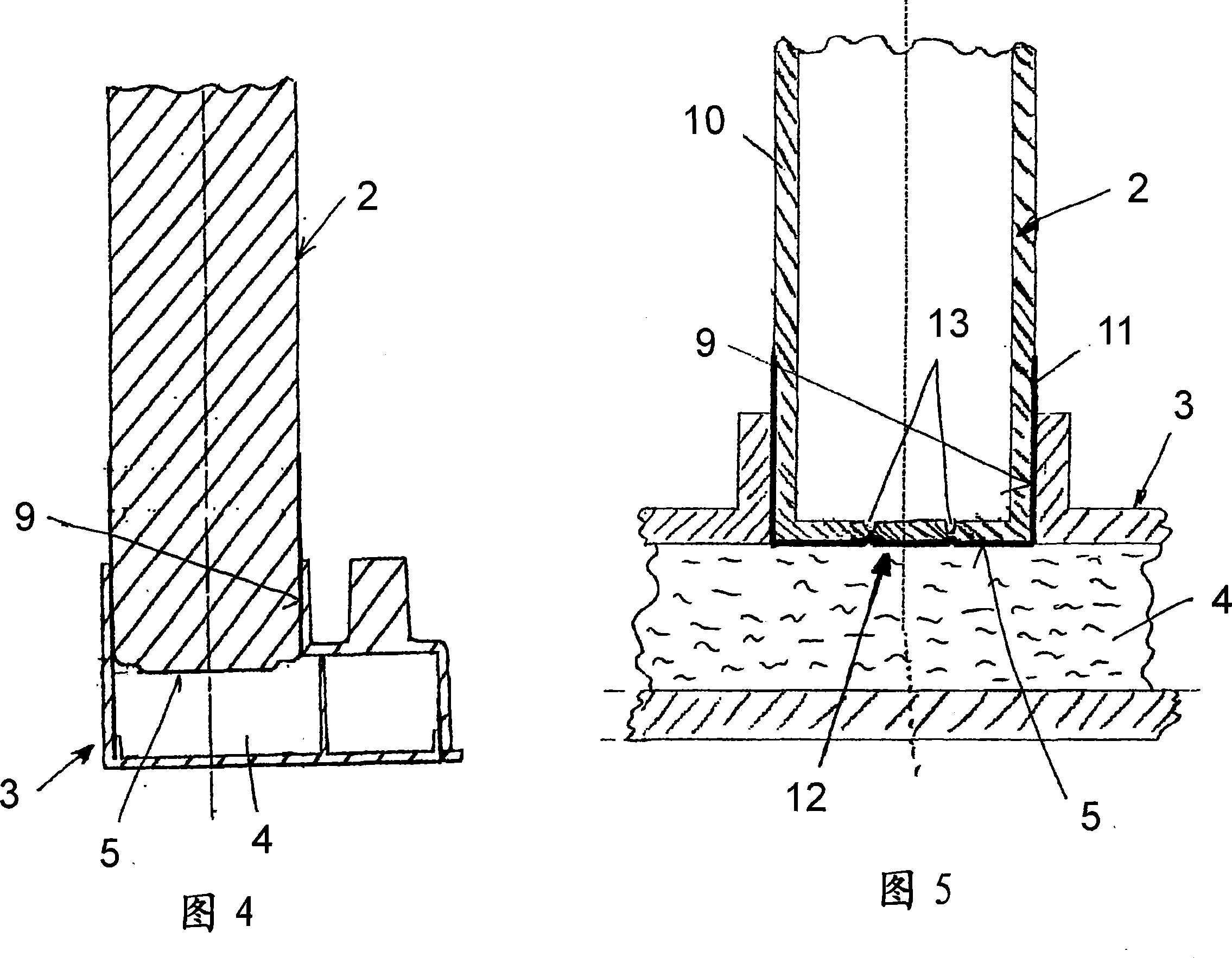

[0022] In addition, the battery is cooled by means of a cooler 3 having an internal space 4 (not shown in FIG. 1 ) through which a cooling medium can flow, through which the cooling medium flows during normal use. Each energy storage unit 2 is in thermal contact with the cooler 3 at its respective end faces 5 (not shown in FIG. 1 ). Said end face forming the bottom 5 of the energy storage uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com