Residual-heat reclamation type cold-hot water energy-saving machine set

A waste heat recovery and energy-saving unit technology, applied in heating methods, space heating and ventilation details, ventilation and heating energy recovery systems, etc., can solve problems such as insufficient use of heat energy, waste of energy and resources, and energy consumption, etc., to achieve Recycle and make full use of waste heat, save energy and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

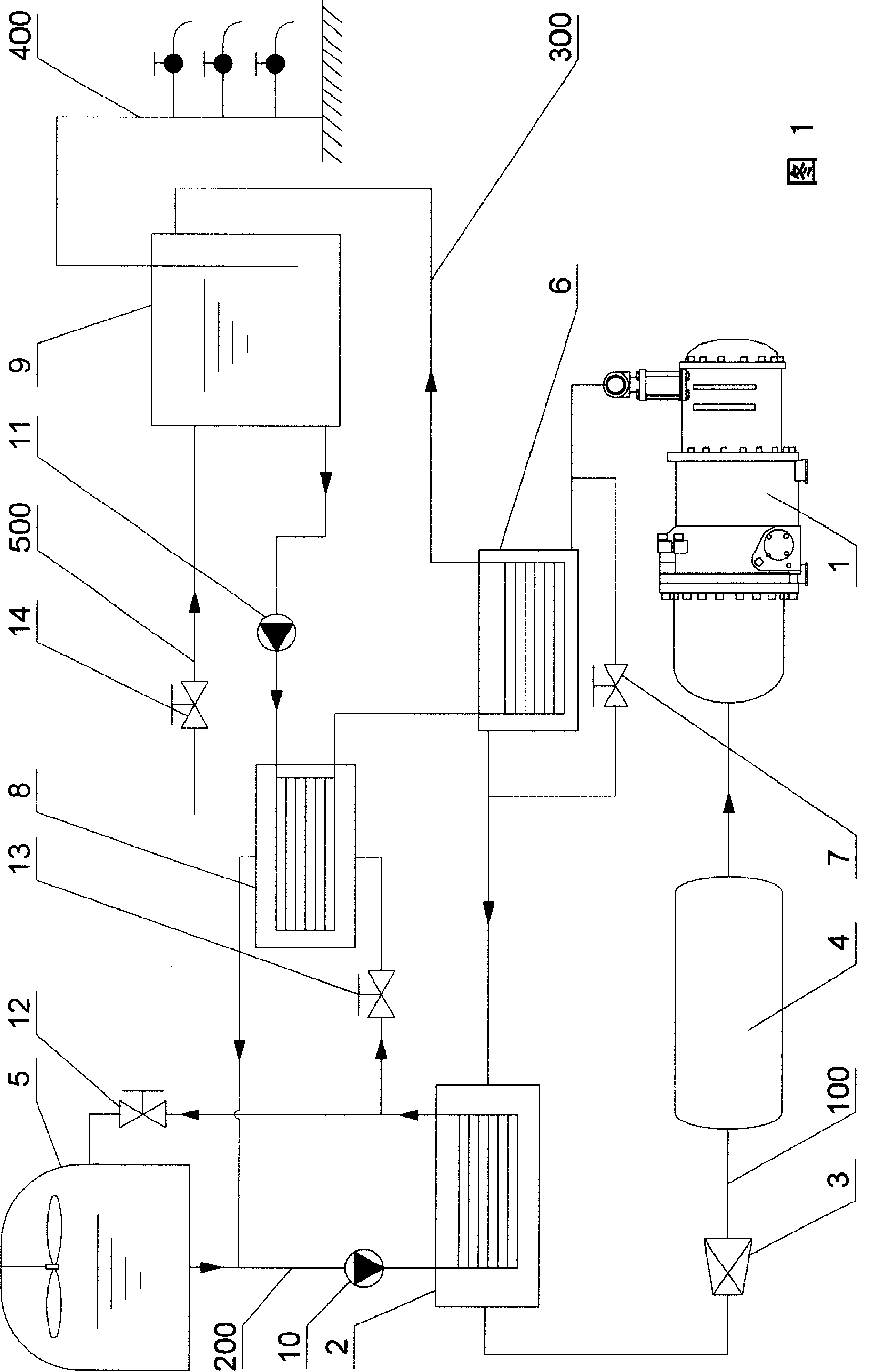

[0009] As shown in Figure 1, the present invention includes a water chiller and a cooling water circulation system. The water chiller includes a compressor 1, a condenser 2, an expansion valve 3, and an evaporator 4, which are sequentially connected through a refrigerant pipeline 100 to form a refrigeration cycle. loop, the cooling water circulation system includes a cooling tower 5, a cooling water pump 10, and a condenser 2 and is sequentially connected through a cooling water circulation pipe 200 to form a cooling water circulation loop, and the waste heat recovery type cold and hot water energy-saving unit also includes a heat exchanger 6 , bypass valve 7, II heat exchanger 8, hot water tank 9, hot water circulation pump 11, cooling water valve 12, cooling water circulation valve 13, cold water supply valve 14, cold water inlet pipeline 500, hot water circulation pipeline 300 1. The user hot water pipeline 400, the working medium side of the I heat exchanger 6 and the bypas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com