Automatic loading and unloading mechanical arm

A technology of automatic loading and unloading and manipulator, which is applied in the direction of manipulator, metal processing, chuck, etc. It can solve the problems of the rotation angle and flexibility to be improved, the overall structure is complicated, and the production cost is high, so as to achieve simple structure, wide application range and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

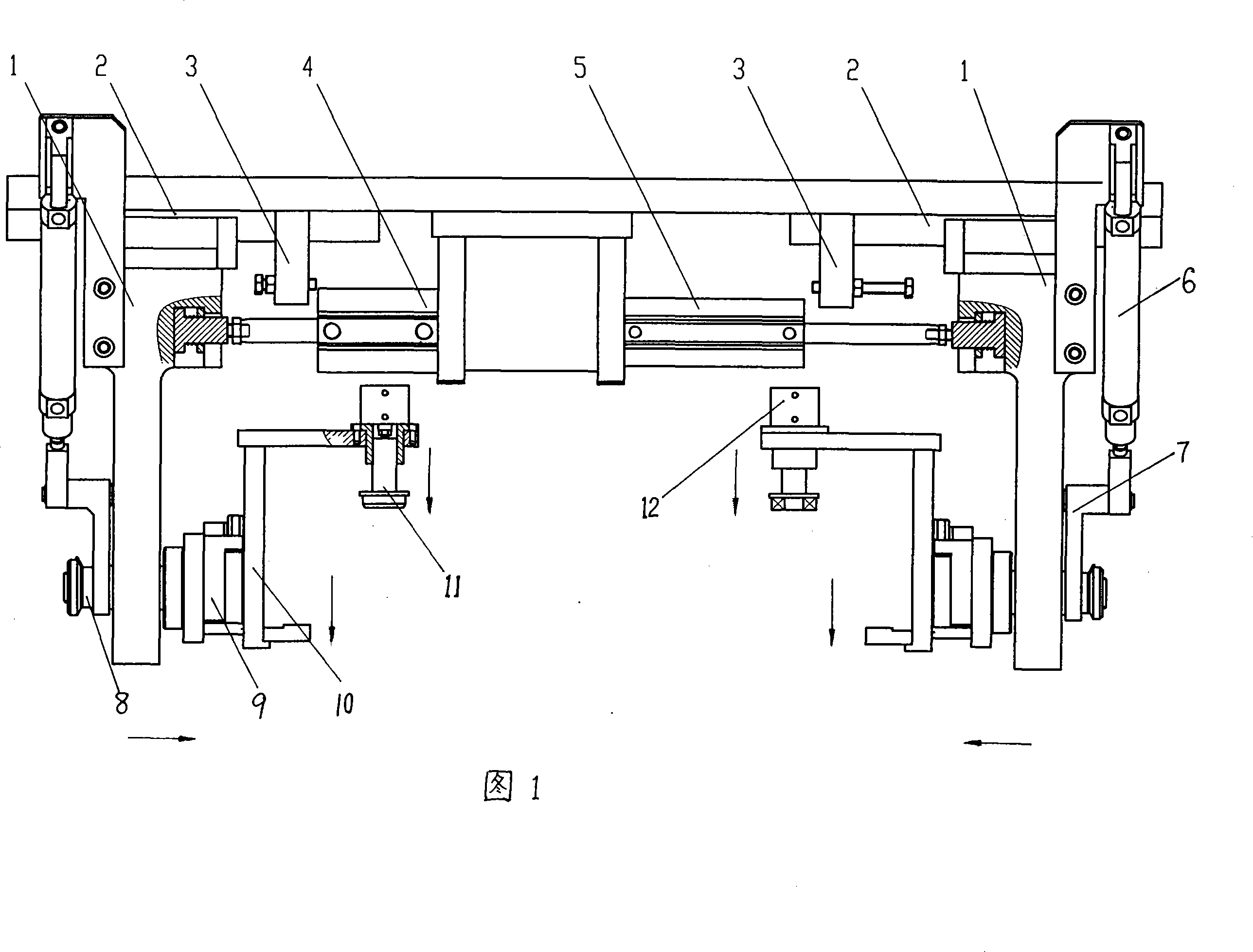

[0013] The automatic loading and unloading manipulator shown in Figure 1 is mainly composed of positioning, clamping and flipping. The positioning mechanism positioning cylinders 4, 5 and guide rail 2 are respectively fixed on the top plate, and the slider 1 is slid on the guide rail and aligned with the positioning The piston rod of the cylinder is fixedly connected, and the stroke of the positioning cylinder can be adjusted by the iron stopper 3 to meet workpieces of a certain size range. At the same time, the cylinders on both sides adopt different bores and strokes. For workpieces that are clamped by the end face, the clamping function can be completed at the same time. The rotary shaft 8 of the turning mechanism is fixedly connected to one end of the connecting rod 7, and the other end of the connecting rod is connected to the turning cylinder 6 in rotation, and the turning cylinder is fixed on the slider. The block is provided with an angle adjustment block, and the block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com