Holder for cutting tool

A cutting head and shank technology, applied in the direction of tools for lathes, accessories of toolholders, milling cutters, etc., can solve the problem of reduced rigidity of the installation shaft, difficulty in shortening the length of the installation cylinder, and longer protrusion length of the cutting head, etc. problem, to achieve the effect of increasing rigidity, increasing rigidity and shortening distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

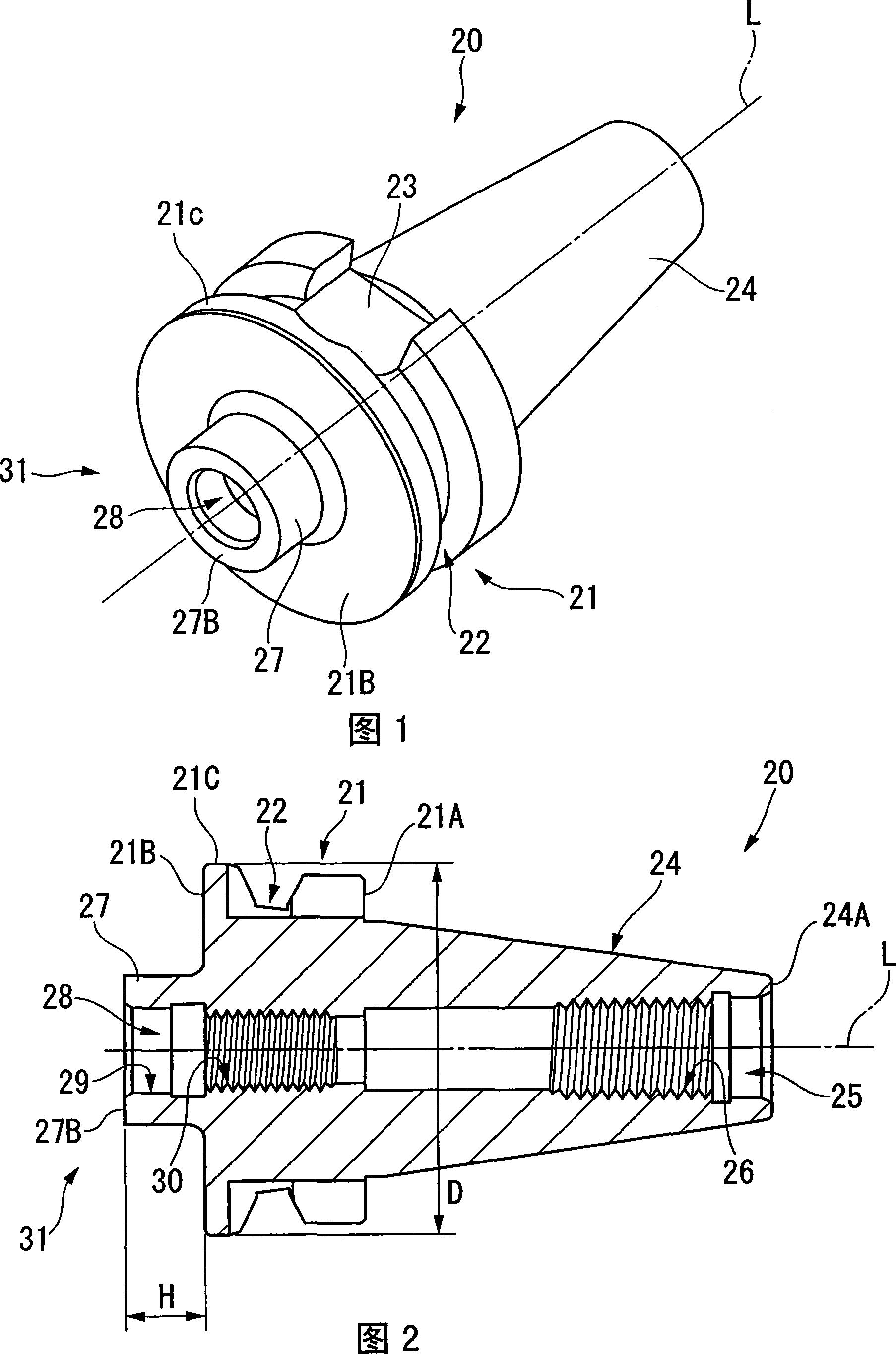

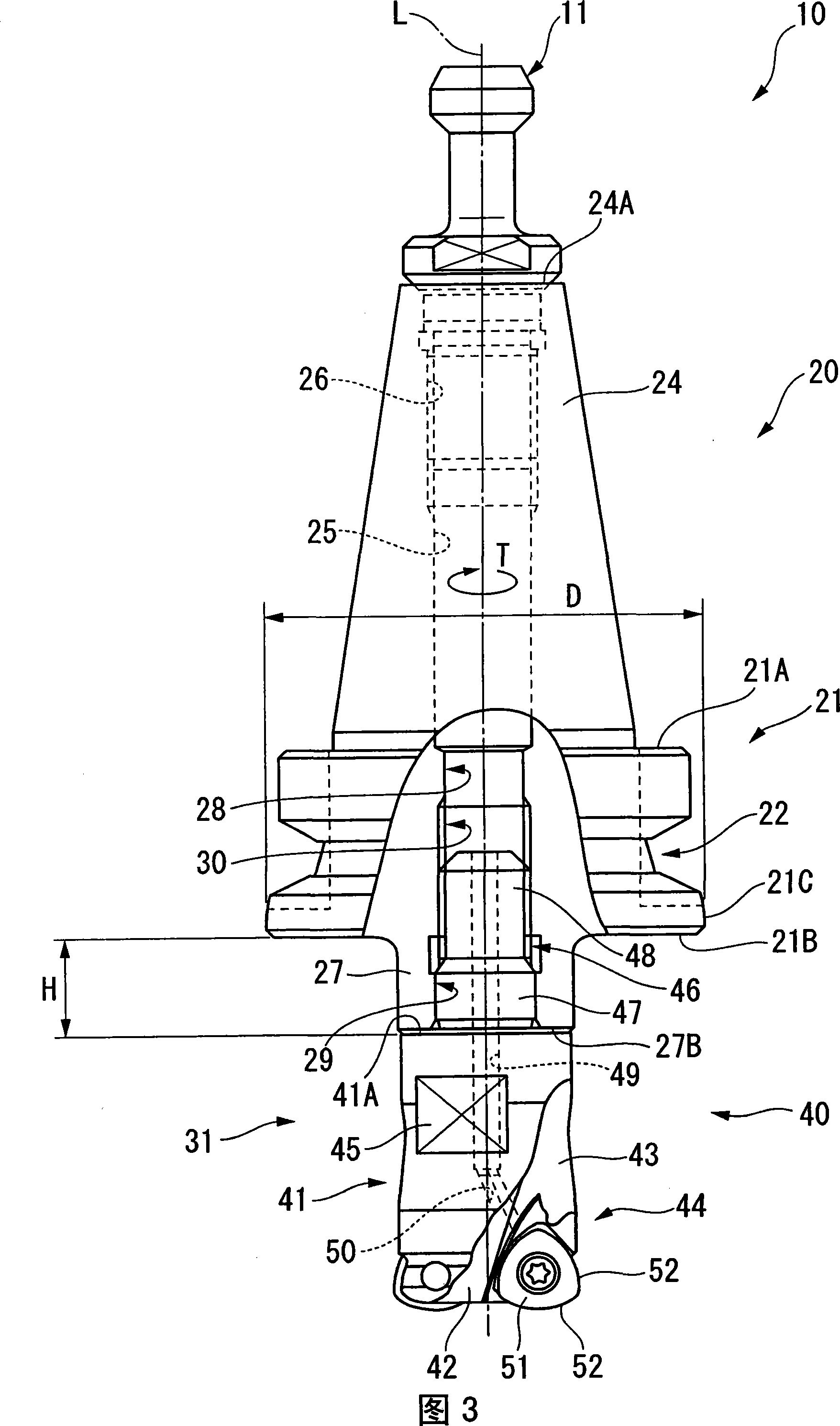

[0052] Hereinafter, embodiments of the present invention will be described with reference to the drawings. 1 and 2 show a tool holder according to this embodiment, and FIG. 3 shows a cutting head replaceable tool equipped with a cutting head.

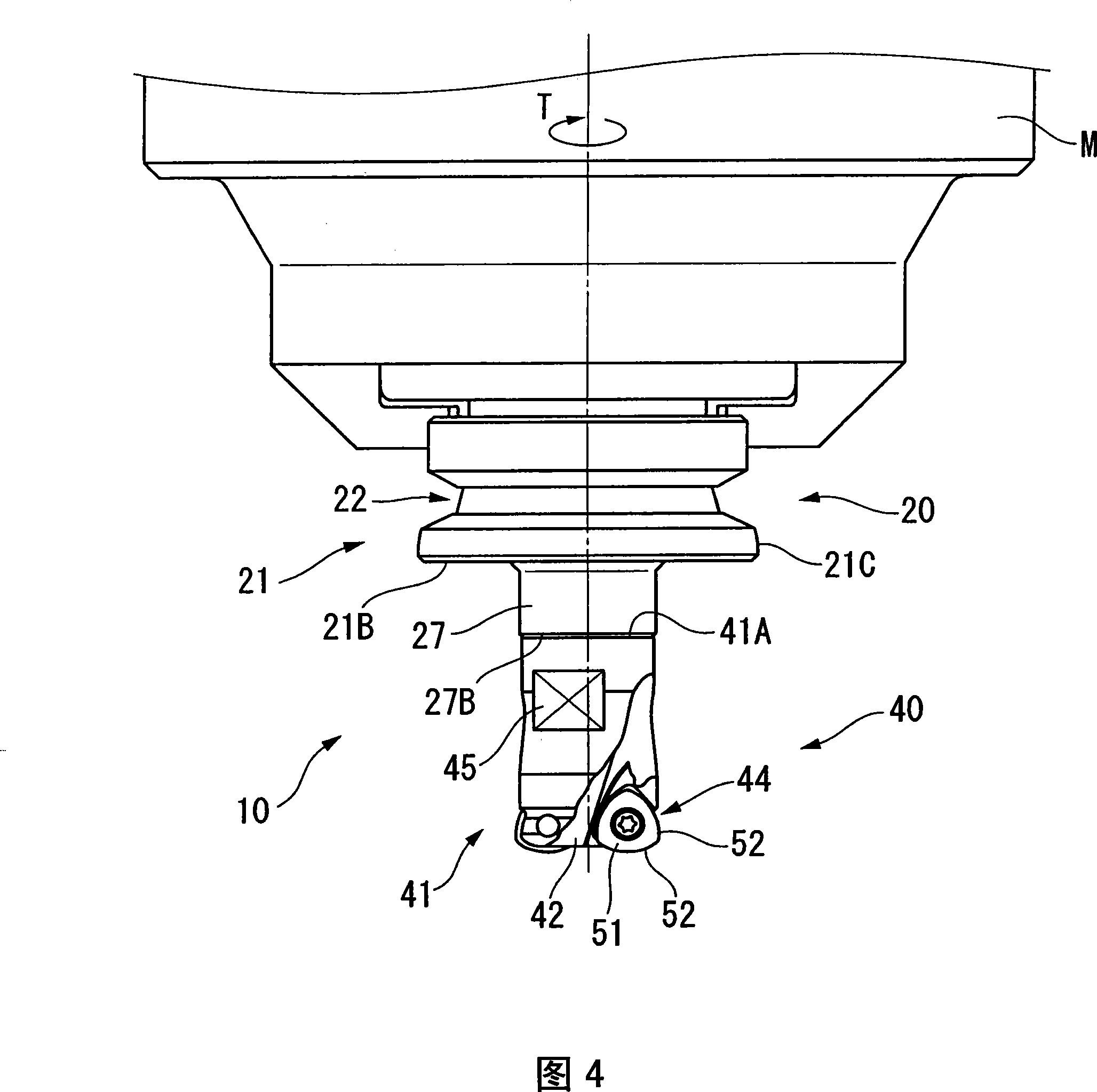

[0053] The cutting head replaceable tool 10 shown in FIG. 3 is mounted on a tool holder 20 mounted on the spindle end of a machine tool M and a cutting head 40 is detachably mounted on the cutter holder 20 .

[0054] As shown in FIG. 1 , the tool holder 20 has a substantially multi-stage cylindrical shape extending along the axis L, and includes a gripping portion 21 protruding radially outward around the axis L. As shown in FIG. An annular groove 22 recessed radially inward from the outer peripheral surface is formed in the center portion of the grip portion 21 in the axis L direction. In addition, at the part closer to the proximal side (the upper right side in FIG. 1 and the right side in FIG. 2 ) than the annular groove 22 of the g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap