Catalyst for polymerization of ethylene or combined polymerization, producing method and application of the same

A technology of ethylene polymerization and catalyst, which is applied in the application field of olefin polymerization or copolymerization, can solve the problems of catalyst apparent density to be improved and catalyst polymerization activity high, and achieve concentrated particle size distribution, less fine powder, and high apparent density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

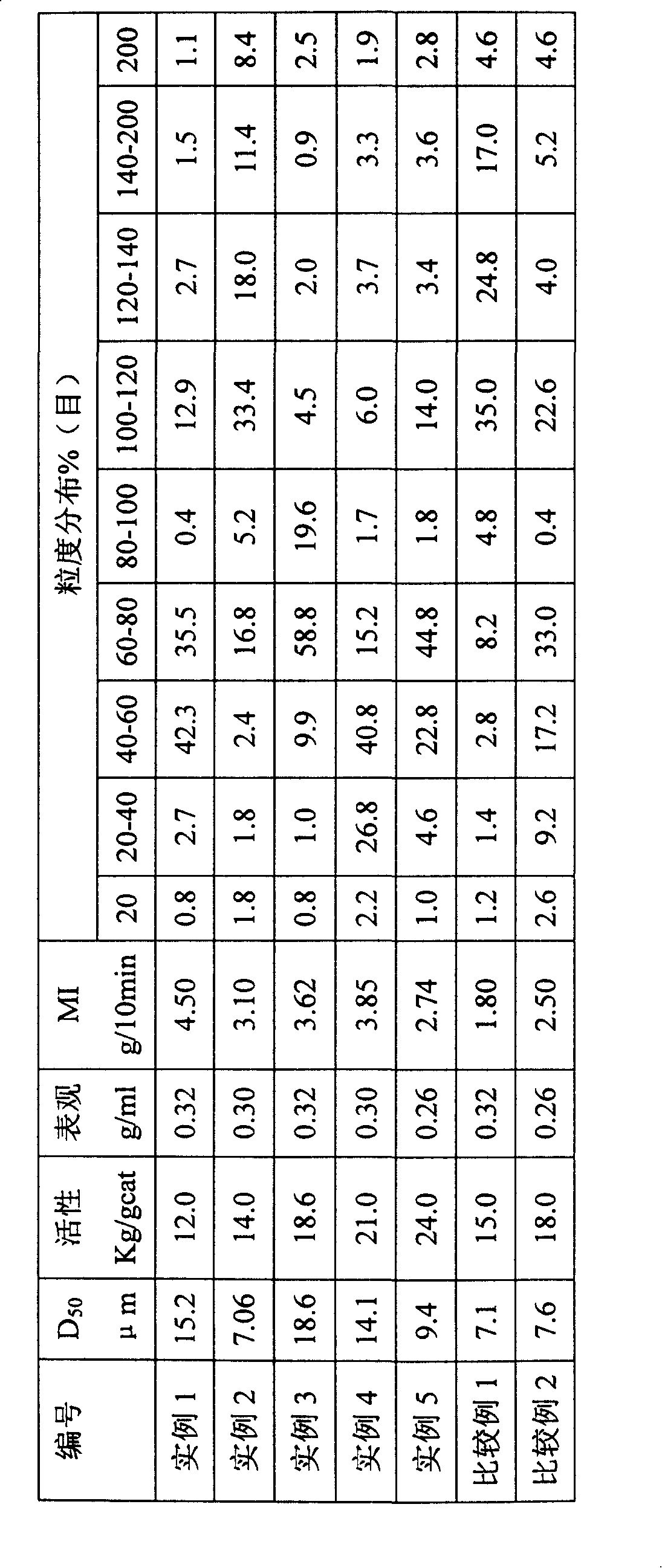

Examples

Embodiment 1

[0028] Embodiment 1: After high-purity N 2 In the fully replaced reactor, add 4.0g of anhydrous MgCl successively 2 , 50ml of toluene, 2.0ml of epichlorohydrin, 3.0ml of tributyl phosphate, heated up to 50°C with stirring, and maintained for 15 minutes, added 6.0ml of ethanol, continued to react for 15 minutes, and cooled the solution to -5~0°C , then drop the mixture of 30ml titanium tetrachloride and 30ml heptane into it, then add 2ml hydroxypropyl methacrylate, slowly heat the solution to 80°C, and react at this temperature for 2 hours. Filter, wash 4 times with hexane, and dry in vacuo to obtain a solid catalyst.

[0029] (2) Ethylene polymerization: a stainless steel kettle with a volume of 2 liters is passed through H 2 After sufficient replacement, add 1000ml of hexane, 1.5ml of triethylaluminum (1mol / L hexane solution), metered (5-6mg) of the solid catalyst component prepared above, and heat up to 70°C for hydrogenation at 0.26MPa , and then feed ethylene to make th...

Embodiment 2

[0030] Embodiment 2 (one) Catalyst synthesis: Same as embodiment 1, only change hydroxypropyl methacrylate into 4ml.

[0031] (two) ethylene polymerization is with embodiment 1.

Embodiment 3

[0032] Embodiment 3: (1) Catalyst synthesis: same as embodiment 1, only change the added hydroxypropyl methacrylate into 2 ml of hydroxyethyl methacrylate.

[0033] (two) ethylene polymerization is with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap