Blue flare subsection air feed gas water heater

A technology for gas water heaters and flames, which is applied in water heaters, fluid heaters, lighting and heating equipment, etc. It can solve problems such as difficult to ensure the state of blue flames and changes in the proportion of secondary air, and achieve smooth exhaust and heat exchange Full, fully burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

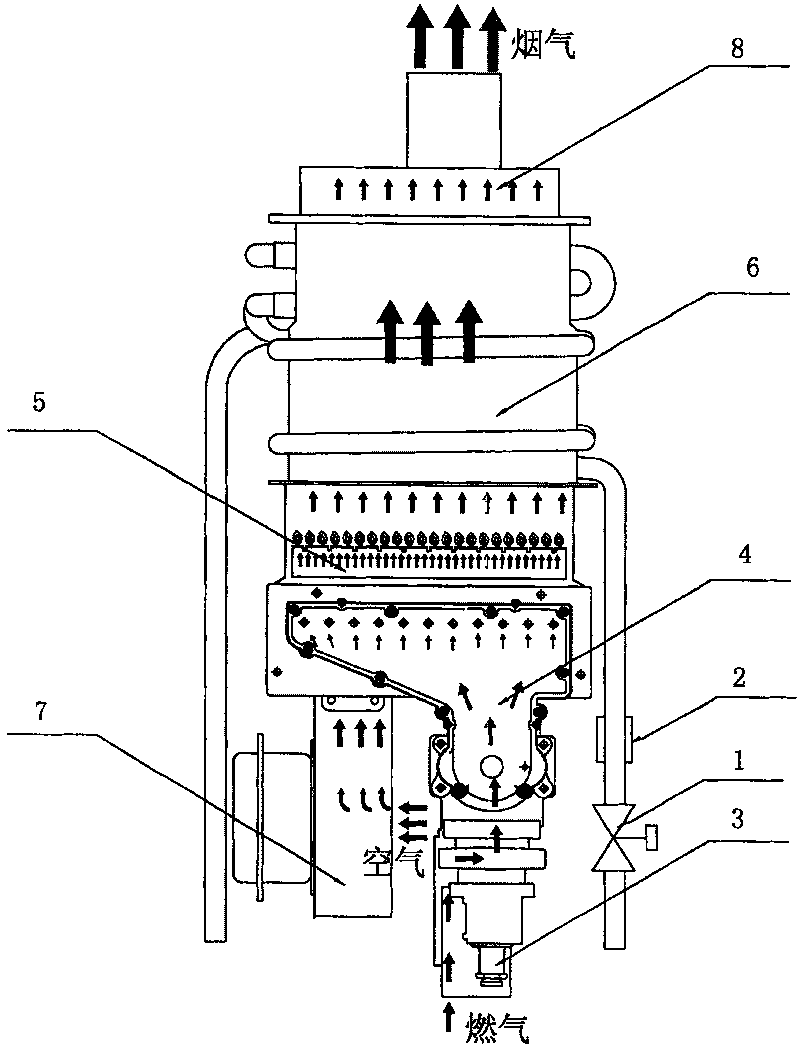

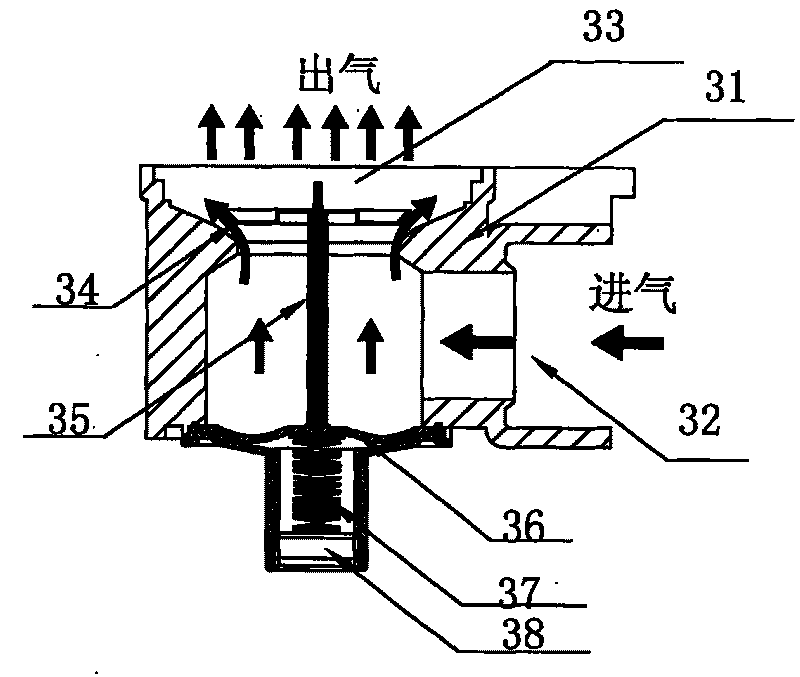

[0039] Its structure of the blue flame sectional air supply gas water heater provided by the present invention is as follows: figure 2 As shown, it mainly includes: water inlet valve 1, water inlet flow sensor 2, gas valve 3, pulse igniter, multi-row fire row burner 5, heat exchanger 6 and fan, and the difference with the existing gas water heater is that : a 3-way distributor 9 is set at the gas channel position of the existing gas water heater, the gas valve is connected to the 3-way distributor 9 through 2 solenoid valves, and the 3-way distributor is formed by 2-way gas Composed of channels, the 2-way gas channels in the 3-way distributor 9 are respectively connected to the gas valves through solenoid valves, and each of the distributors is provided with a plurality of gas nozzles 91 (such as Figure 4a , Figure 4b , Figure 5 shown), each gas nozzle 91 is facing the injection hole 52 of a fire row burner 5 (referring to Figure 7); any solenoid valve conduction const...

Embodiment 2

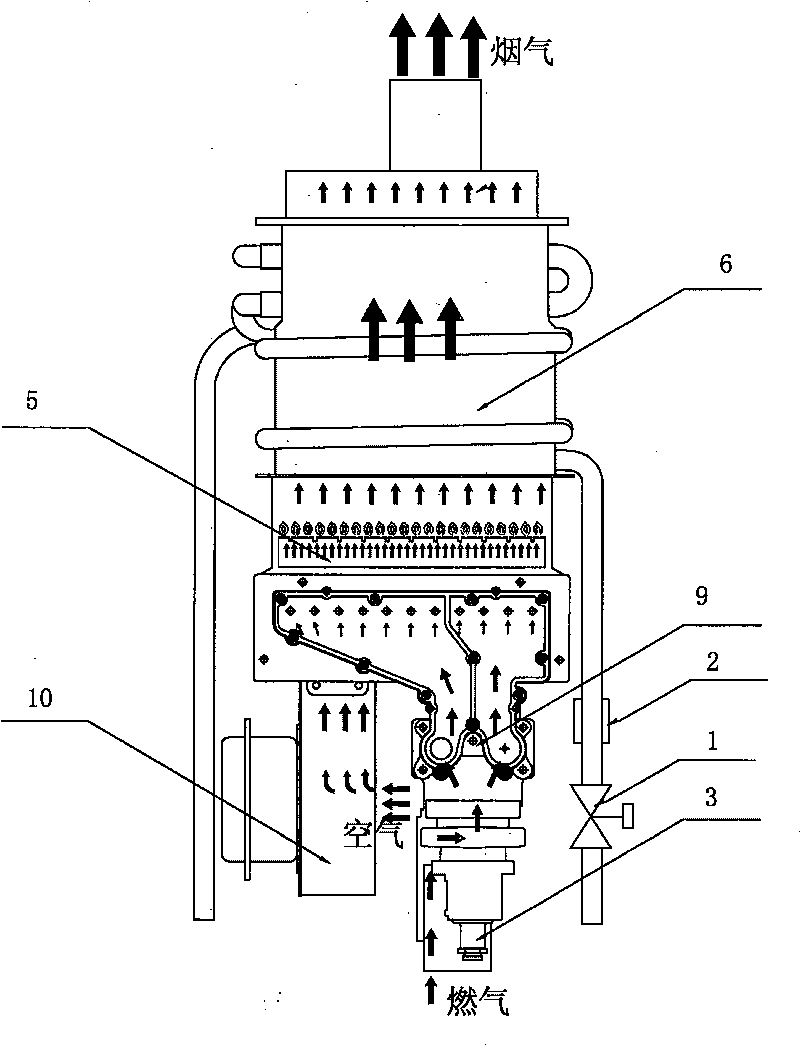

[0053] It is another embodiment of the blue flame segmental air supply gas water heater of the present invention. This embodiment is basically the same as Embodiment 1, and also includes: water inlet valve 1, water inlet flow sensor 2, gas valve 3, pulse igniter , multi-column fire row burner 5, heat exchanger 6 and blower fan 10, and its difference is that distributor is different: the used distributor of present embodiment is 3 passages 7 road distributors, and its structure is as follows Figure 4c As shown, the gas valve is respectively connected to the 3 channels of the 7-way distributor through 3 solenoid valves, one of the 7-way distributors is provided with 4 gas nozzles, and the other of the 7-way distributors is provided with There are 6 gas nozzles, and the other one of the 7-way distributors is provided with 8 gas nozzles, and each gas nozzle is facing the injection hole of a fire row burner; the fan is a 7-speed fan.

[0054] The number of fire row burners corresp...

Embodiment 3

[0064] This embodiment is basically the same as Embodiments 1 and 2, and also includes: water inlet valve 1, water inlet flow sensor 2, gas valve 3, pulse igniter, multi-row fire row burner 5, heat exchanger 6 and fan 10 , the difference is that the distributor is different: the distributor used in this embodiment is an n-channel n-way distributor, and its structure is as follows Figure 4d As shown, the gas valve is respectively connected to the n-1 channels of the n-way distributor through n-1 solenoid valves, one of the n-way distributors is directly connected to the gas valve, each distributor A plurality of gas nozzles are provided, and each gas nozzle is directly facing the injection hole of a fire row burner; the fan is an n-speed fan.

[0065] This embodiment is more versatile and can provide more hot water with different temperatures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com