Motor structure

A motor and stator structure technology, applied in the direction of structural connection, magnetic circuit shape/pattern/structure, and winding conductor shape/pattern/structure, etc., can solve the problems of inconvenient manufacturing and assembly, difficult alignment, and easy falling off of coils.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

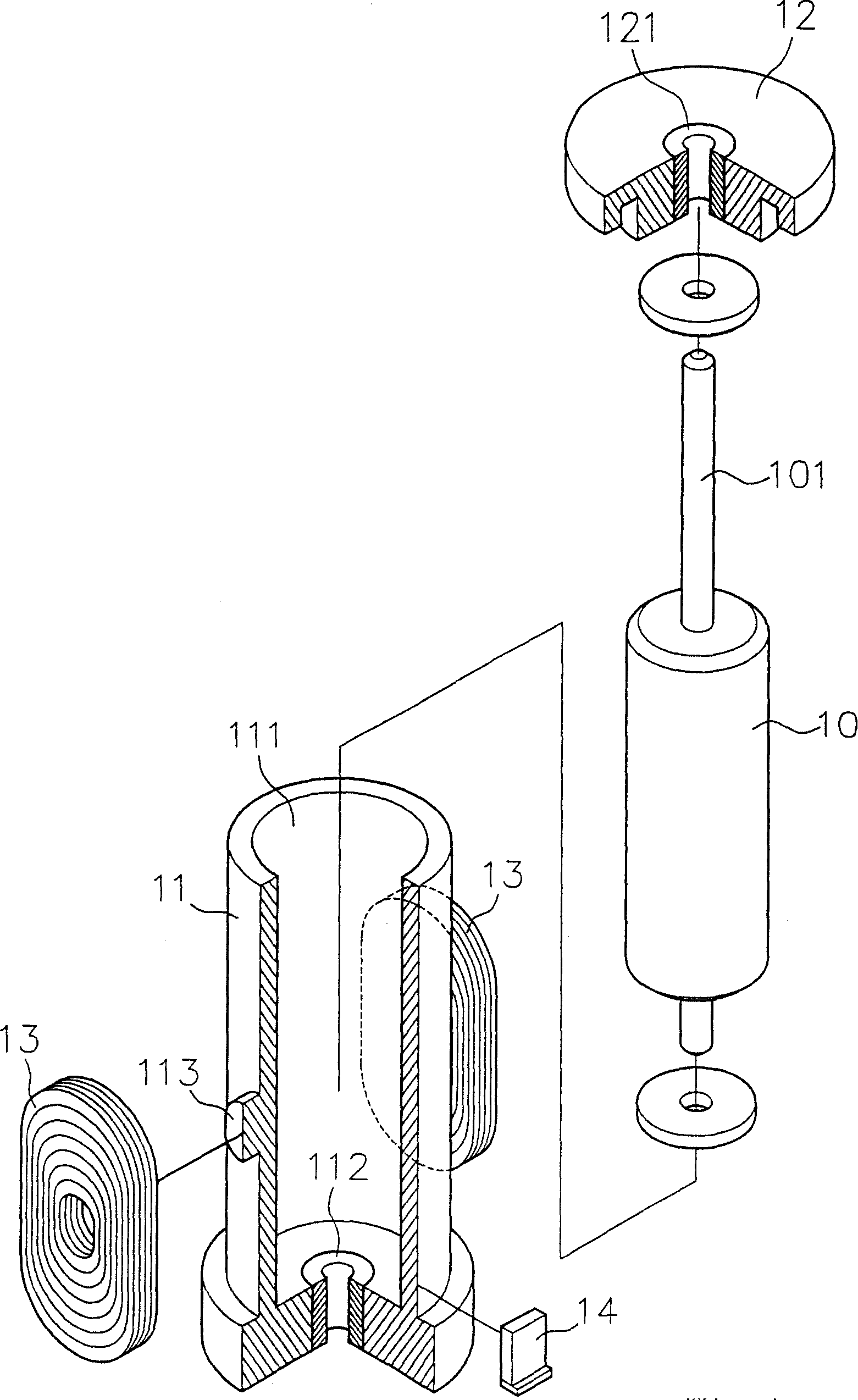

[0026] The invention relates to a motor structure, which arranges components such as coils, motor induction drive components, etc. on a flexible substrate, so that when assembling the stator structure, the steps of assembling and fixing the coils and motor induction drive components and aligning them respectively can be omitted The process makes the manufacture and assembly of the motor structure easier and more convenient.

[0027] Two preferred implementation forms of the present invention are listed below and described with accompanying drawings.

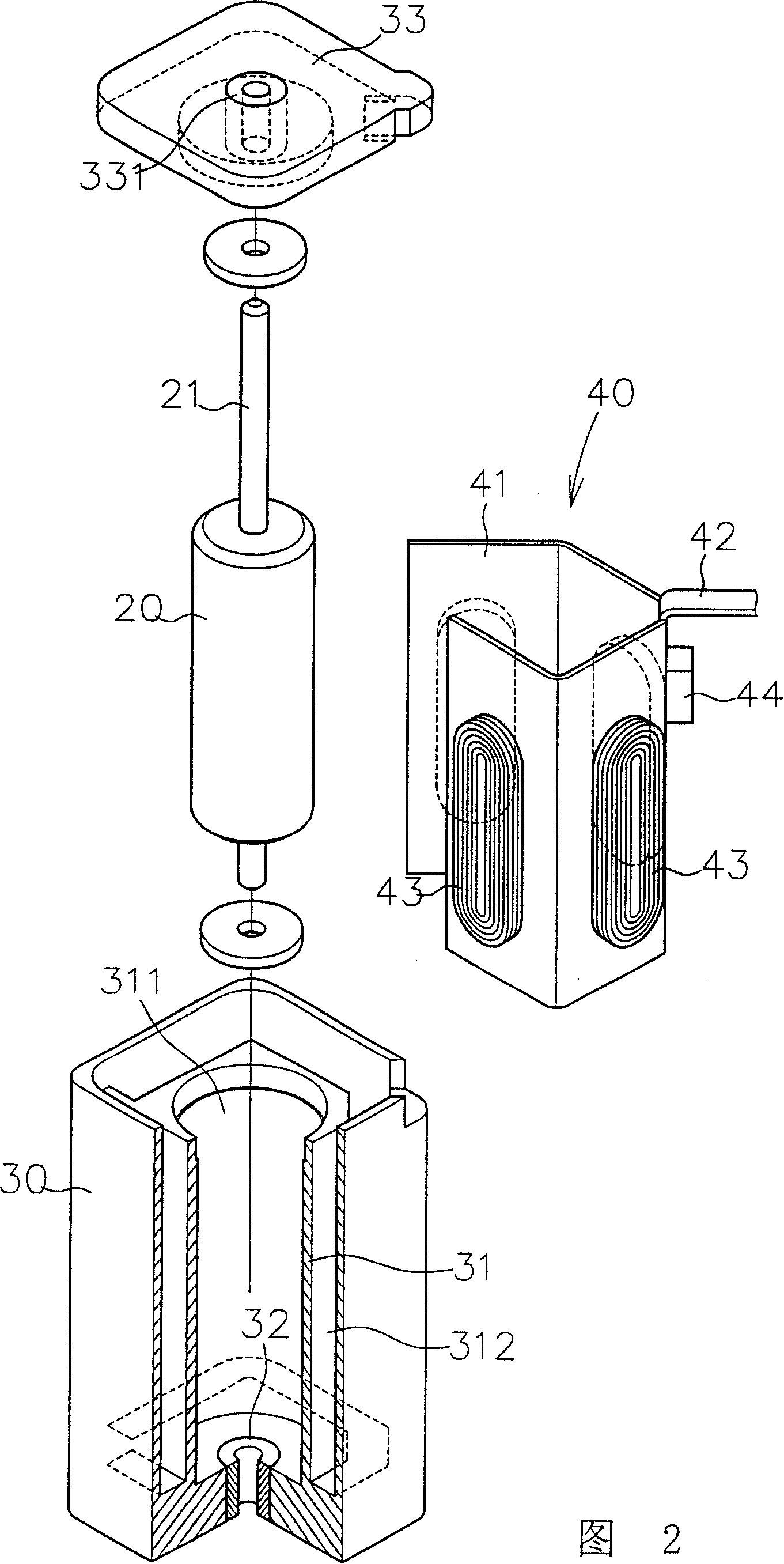

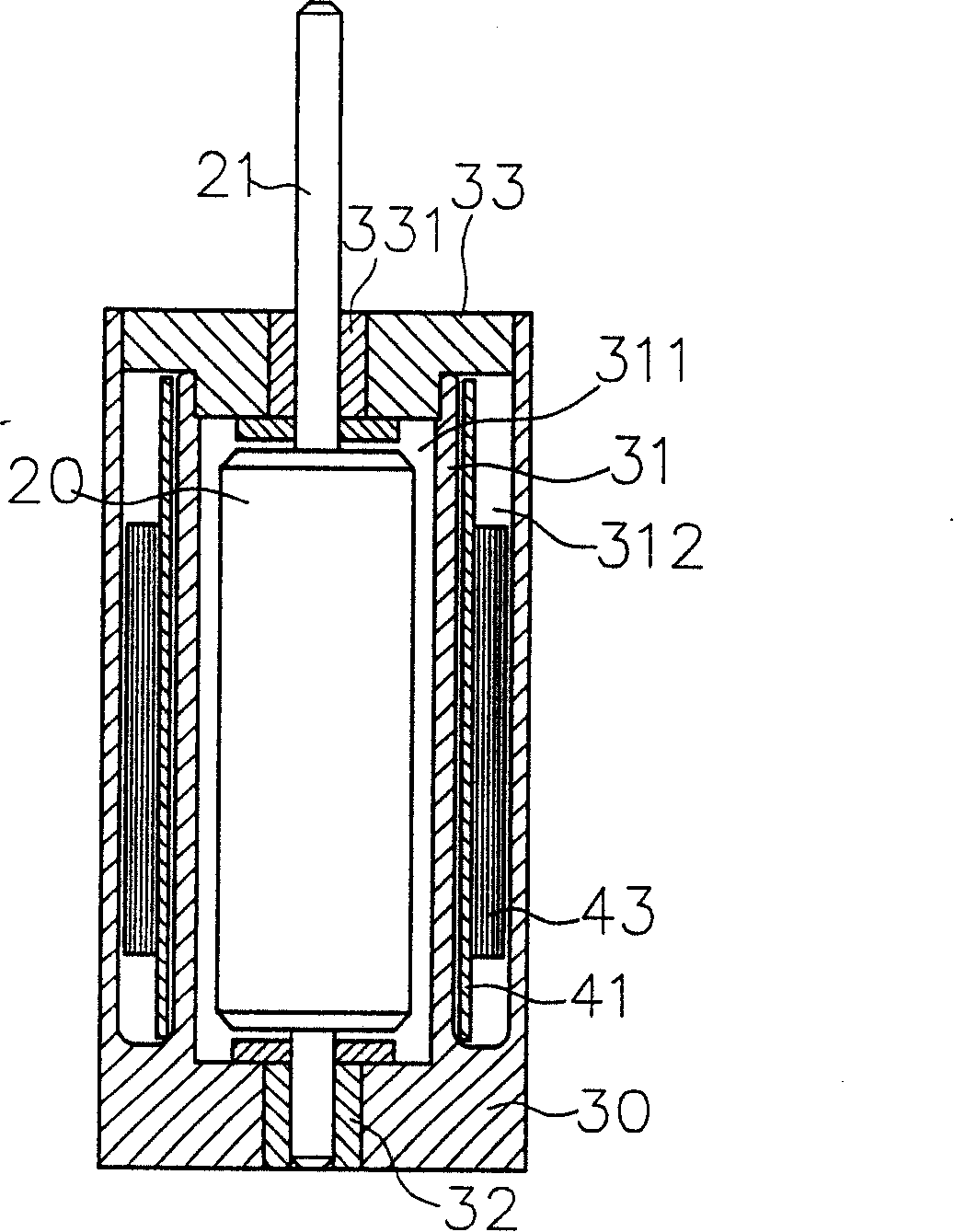

[0028] As shown in Figure 2, image 3 and Figure 4 As shown, it is the first embodiment of the present invention, which includes:

[0029] A rotor 20 is combined with a rotating shaft 21 .

[0030] A shell seat 30, the interior of the shell seat 30 is hollow, and a ring wall 31 is provided. A rotor placement groove 311 is formed inside the ring wall 31, and a stator placement groove 312 is formed on the outer periphery of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com