Transverse and oblique control arm

A technology of transverse and guide arms, applied in the direction of the cantilever mounted on the pivot, elastic suspension, suspension, etc., can solve the problems of danger, high injury, etc., and achieve the effect of weight reduction and high bending rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

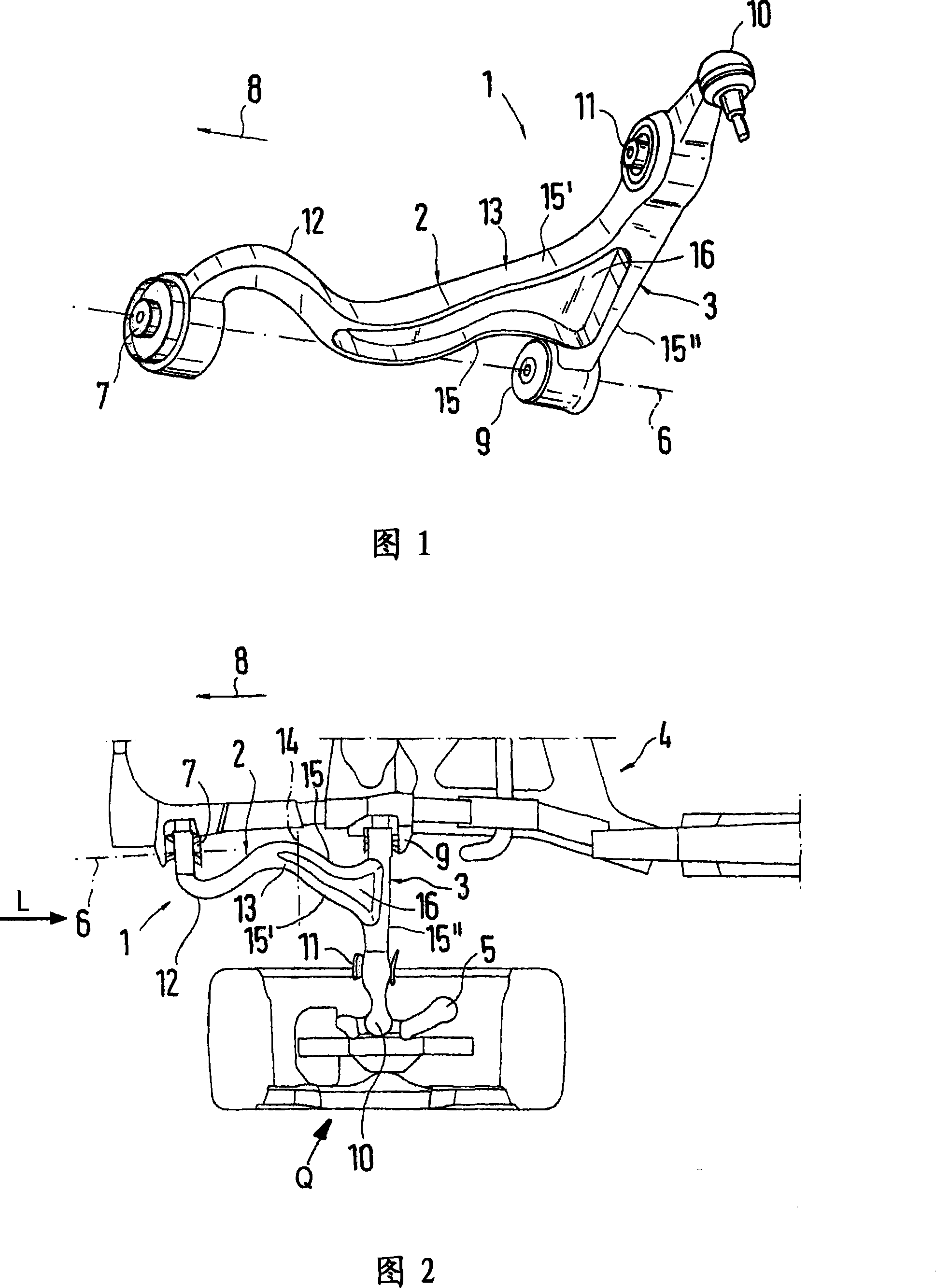

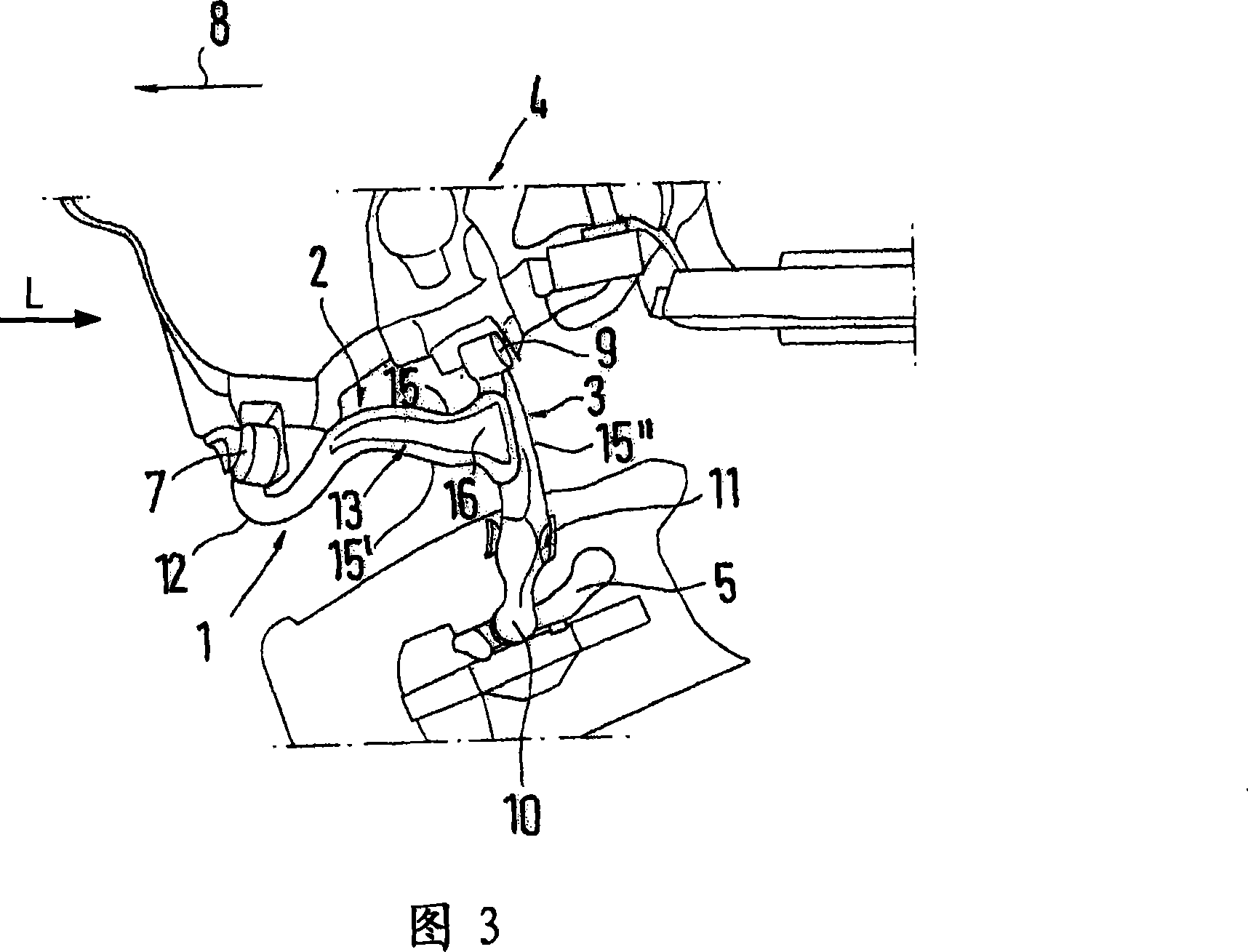

[0016] As shown in FIG. 1 , the lateral or inclined swing arm 1 of the present invention has a first guide arm 2 and a second guide arm 3 . The transverse or inclined swing arm 1 is arranged in a known manner on the front axle of the vehicle (see FIGS. 2 and 3 ) and is articulated on the one hand to the vehicle body 4 and on the other hand to the control lever 5 . In contrast to the spring strut caps, which are not shown, which absorb the vertical forces of the vehicle, the transverse or tilting arm 1 absorbs the horizontal forces that occur during acceleration, braking and cornering. Furthermore, the transverse or oblique pivot arm 1 is pivotable about an axis 6 , wherein the axis 6 approximately passes through chassis-side front joints 7 and rear joints 9 arranged one behind the other in the direction of travel 8 . Thus, when the vehicle is braked, the front universal joint 7 is in tension and the rear universal joint 9 is in compression. The first guiding arm 2 is bent and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com