Coreless wire coil precise winding machine

A winding machine, precise technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of low accuracy, increase production costs, occupy the user's production site, etc., to achieve accurate tracking, The effect of saving production costs and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

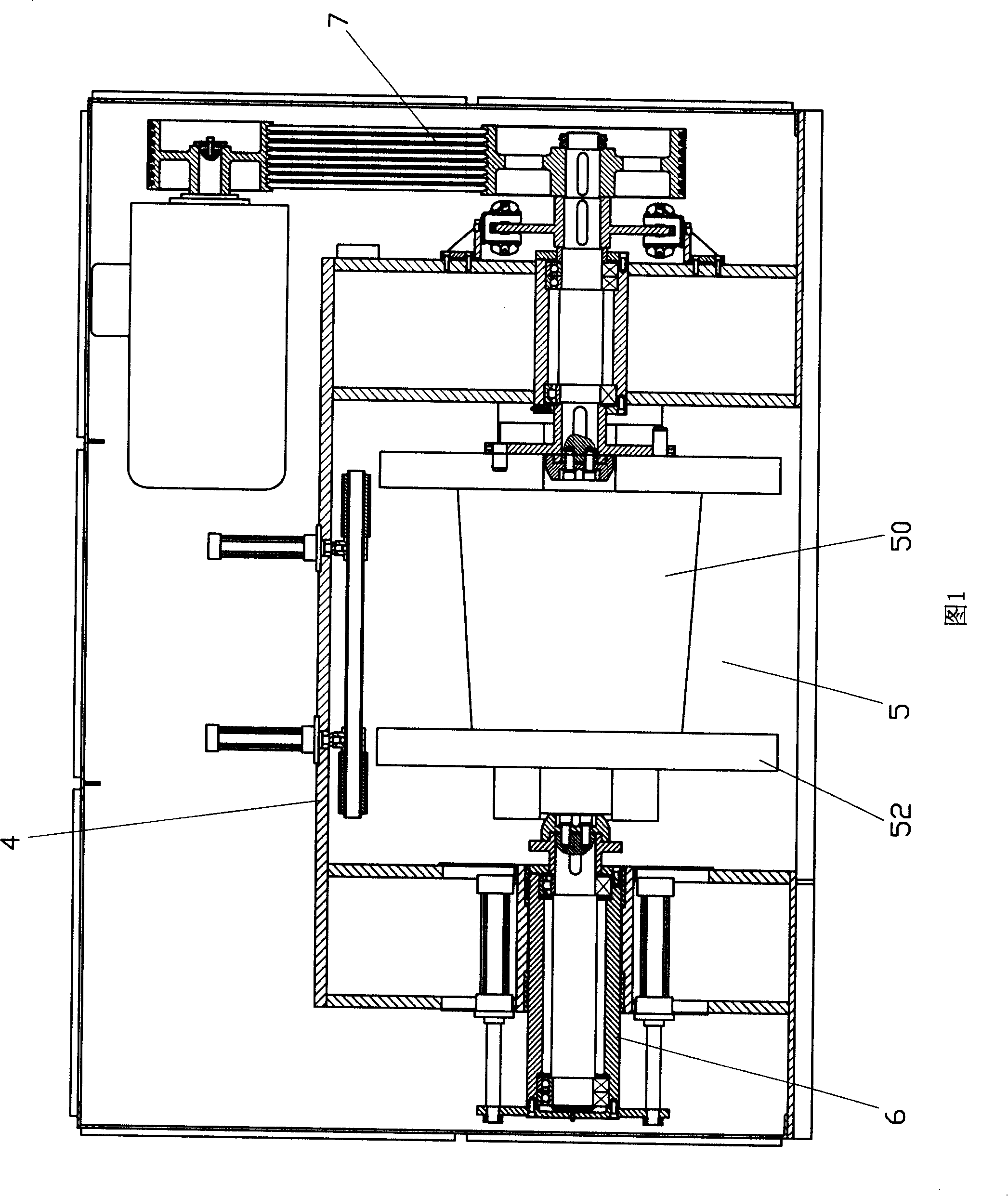

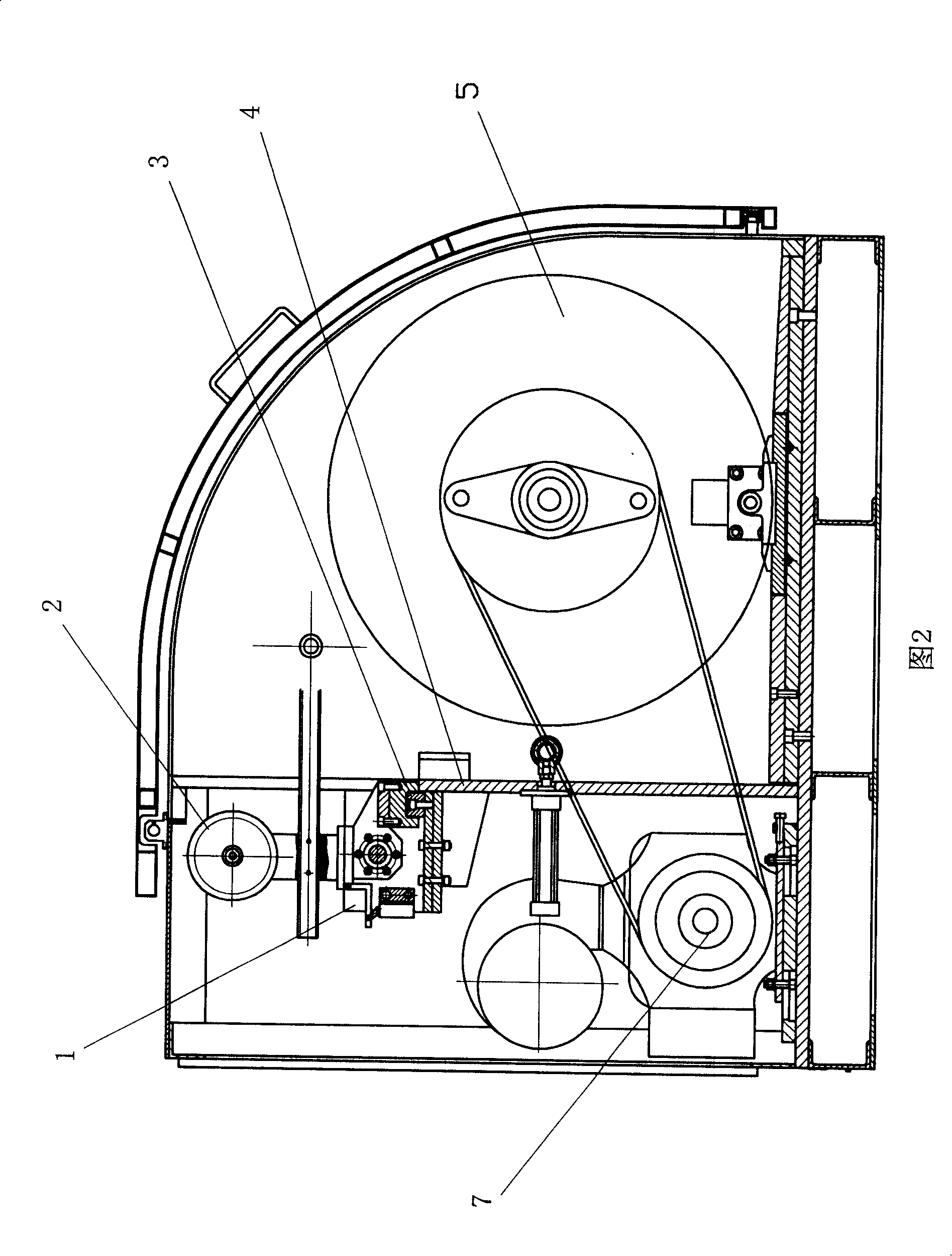

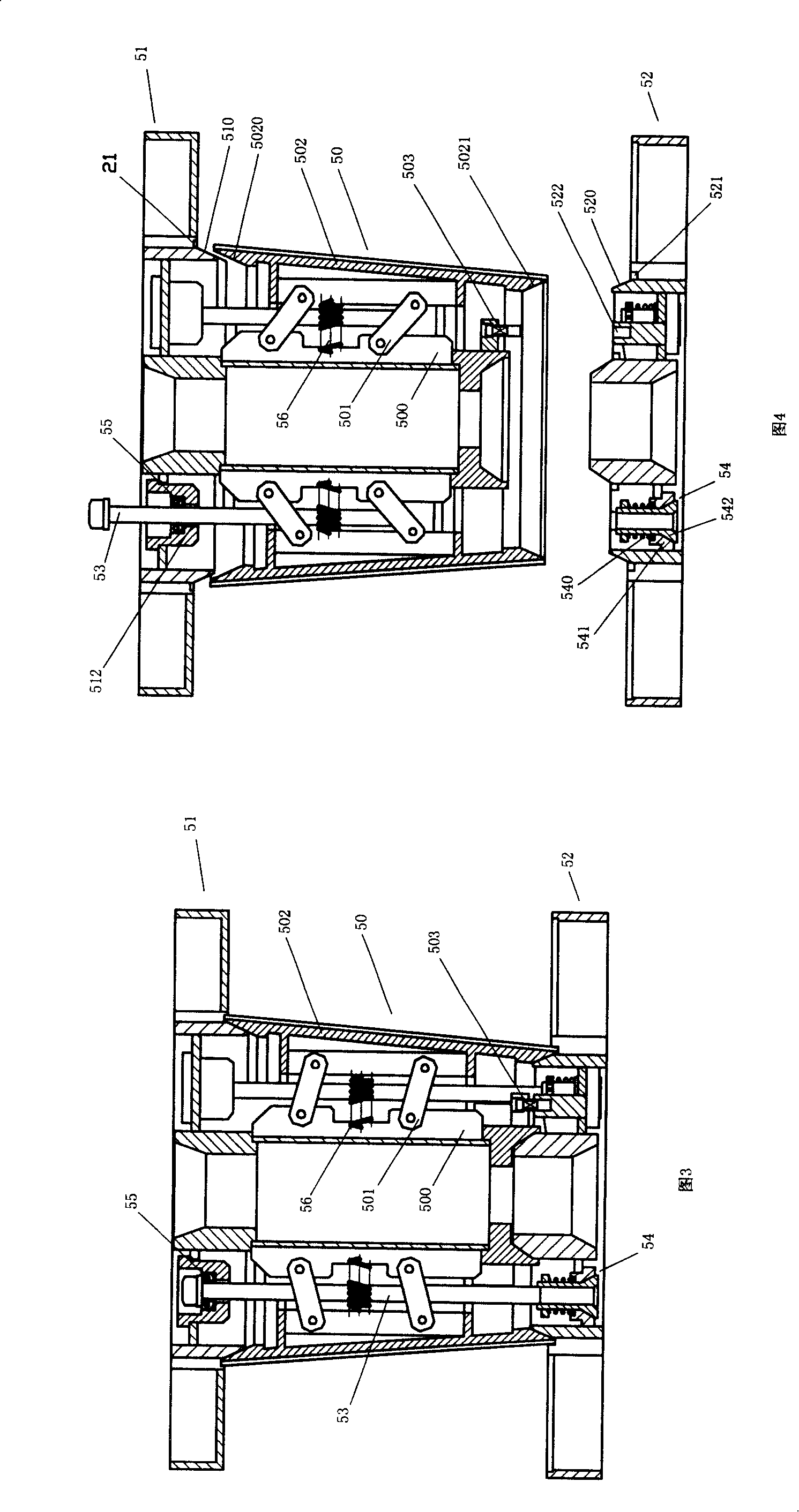

[0027] Referring to Fig. 1 to Fig. 2, a precision winding machine without a core wire reel includes a wire arrangement device and a winding device; the winding device includes a wire reel 5, a clamping device 6 and a driving device 7, and the driving device 7 Drive the wire reel 5 clamped by the clamping device 6 to rotate; the wire reel 5 is provided with an expandable conical shaft core 50, and the second flange 52 on the smaller side of the conical shaft core cross-section and the cone Shaft core 50 is detachably connected. After the finished wire rod is processed, the clamping device 6 releases the wire reel 5, and the wire reel 5 can be disassembled to separate it from the finished wire rod. The finished wire can be handed over to the follow-up users after simple packaging, without occupying the tray, saving production costs and follow-up support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com