Solar cell and solar cell manufacturing method

A technology of solar cells and electrodes, applied in the field of solar cells, can solve the problems of reducing the efficiency of solar cells and increasing the area, and achieve the effects of low cost, small shading and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

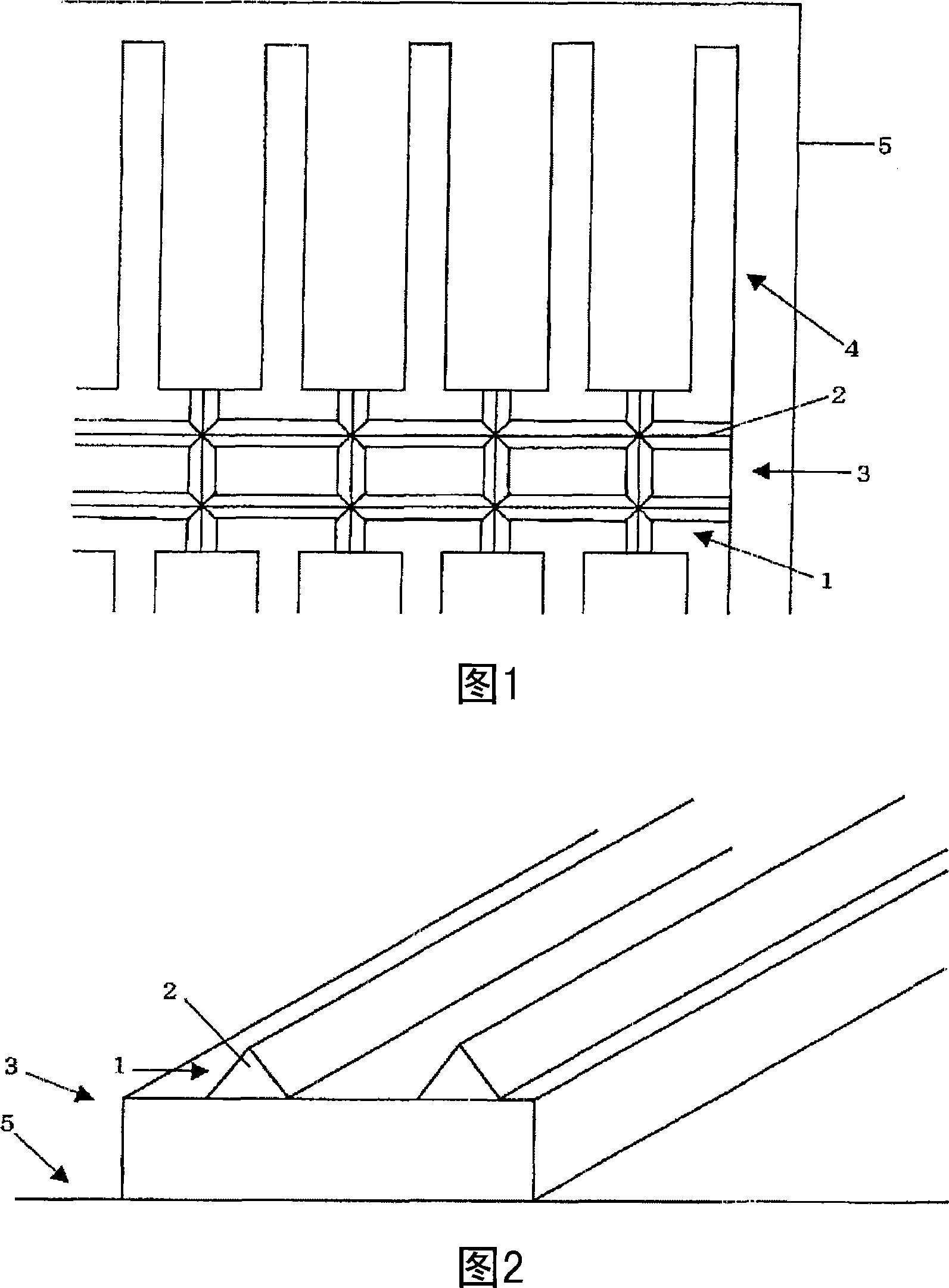

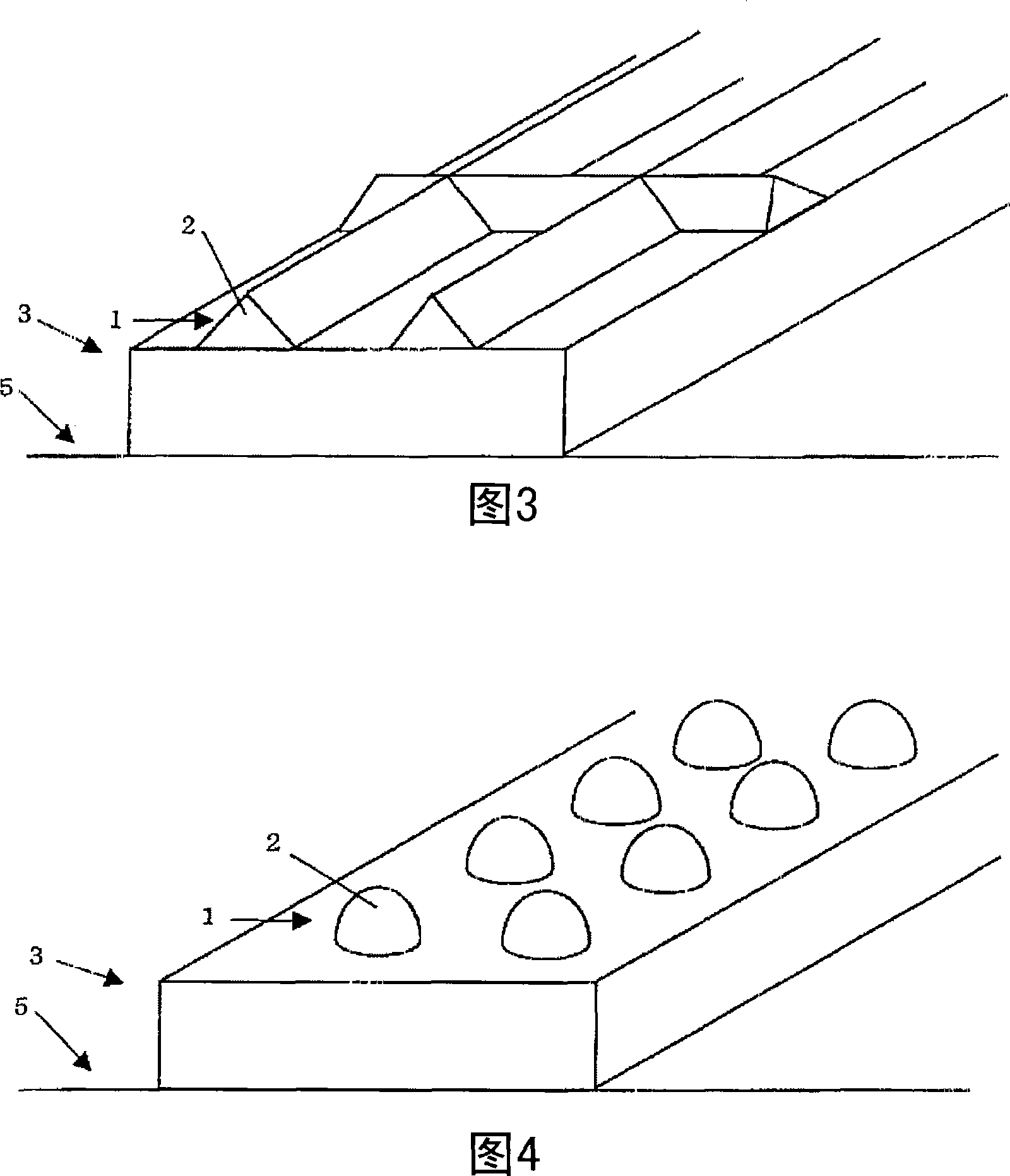

[0032] Since the bus bar electrode will become a shield when sunlight is incident on the substrate, it is necessary to narrow the electrode width, but narrowing the electrode width will reduce the contact area between the bus bar electrode and the connector, and the adhesion strength will decrease. Solder mounted connectors will help with the peeling issue.

[0033] Therefore, after in-depth research, the present inventors have found that: if it is a solar cell, it includes a semiconductor substrate formed with a PN junction, a comb-shaped finger electrode formed on at least one side of the semiconductor substrate, and The bus bar electrode connected to the finger electrode on the substrate, wherein the bus bar electrode is made to have a concave-convex pattern (pattern) formed on its surface, thereby obtaining a solar cell, wherein the connector soldered to the bus bar electrode It is difficult to peel off, and the solar shading caused by the bus bar electrode is small, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com