Shaping drum for tyre shaping machine

A technology of tire building machines and building drums, which is applied to tires, other household appliances, household appliances, etc. It can solve the problems of non-adjustable shrinkage of drum shoulders, insufficient stability of axial and radial forces, and increase convenience. , good rigidity, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

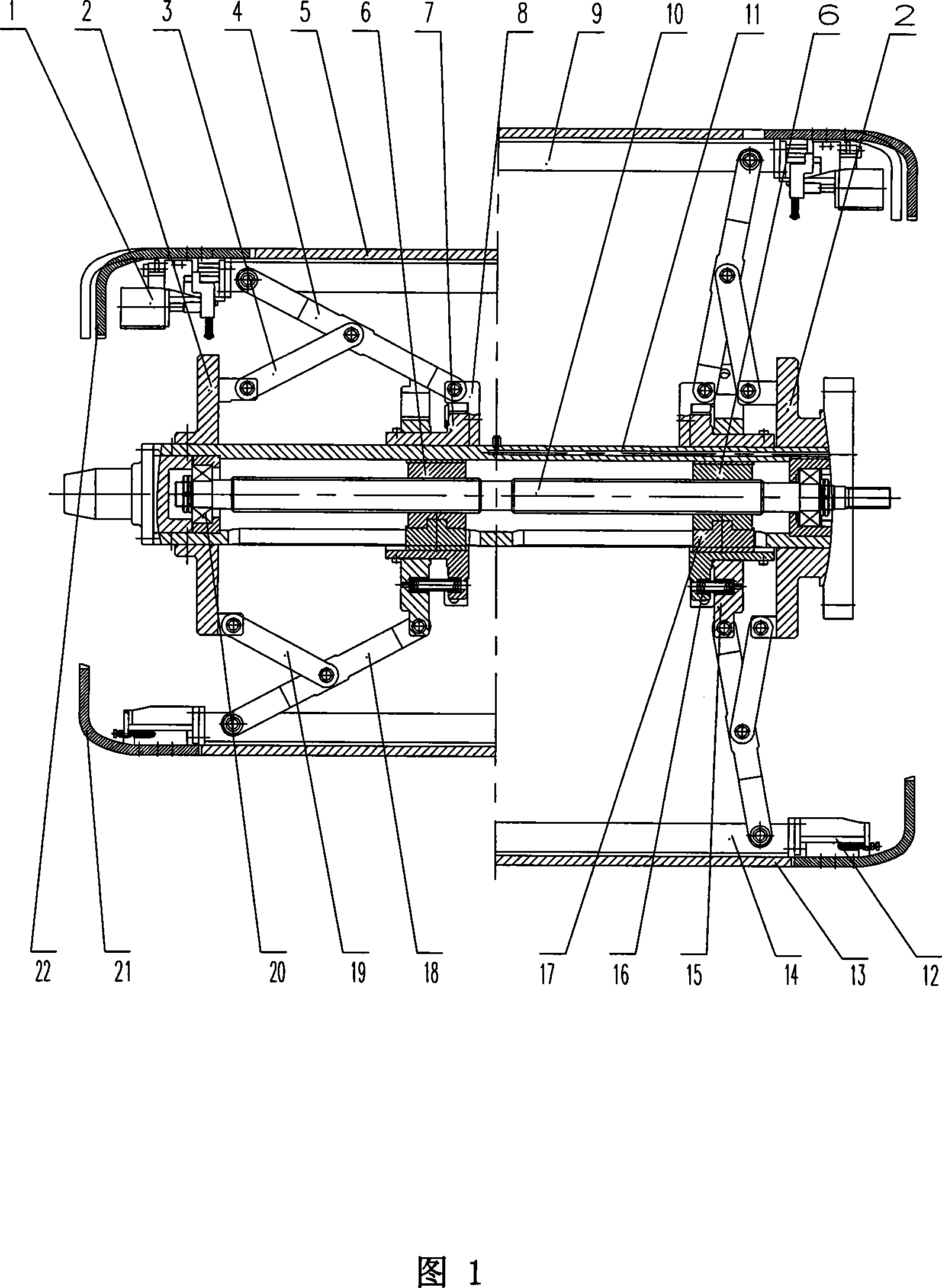

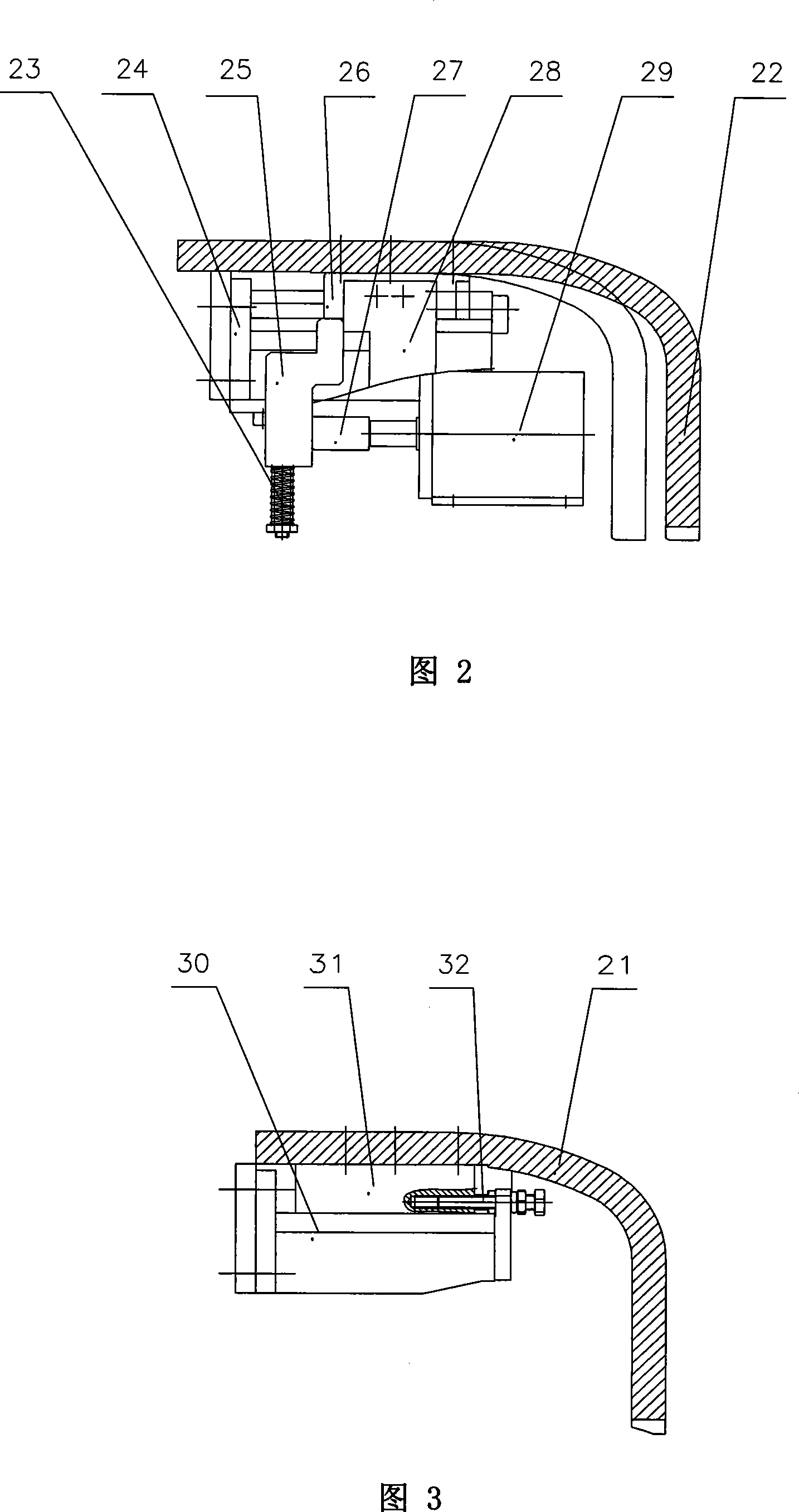

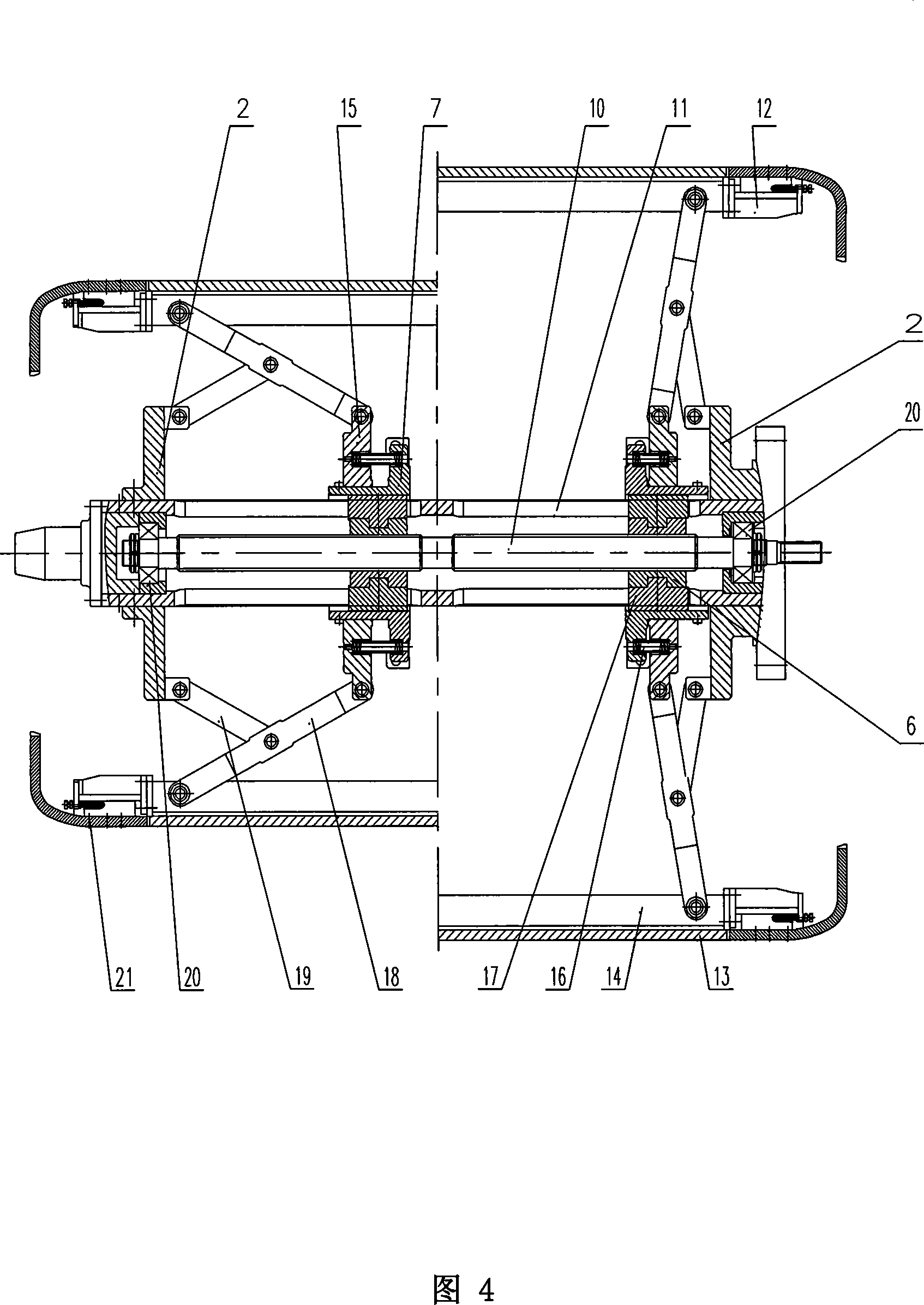

[0030] The tire building machine building drum of the present invention comprises a power transmission mechanism, wide and narrow tile expansion and contraction mechanisms, and wide and narrow tile drum shoulder expansion and contraction mechanisms (12, 1).

[0031] 1. Power transmission mechanism: including the hollow main shaft 11 and the screw nut pair, the hollow main shaft 11 is set horizontally, the screw nut pair is built in the hollow main shaft 11, and the two ends of the screw rod 10 are respectively installed on the two end bearings 20 inside the hollow main shaft 11 Above, the screw mandrel 10 is bounded by the midpoint, and its left and right sections are reverse threads respectively, and the nuts 6 matched with the reverse threads are respectively left and right, as shown in Fig. 1 , Fig. 4 and Fig. 5 .

[0032] 2. Narrow tile expansion and contraction mechanism: including two sets of narrow tile expansion and contraction mechanisms distributed symmetrically on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com