Method of producing optical fiber positioning component, and optical fiber positioning component

一种定位器、光纤的技术,应用在光波导的耦合、光导、光学等方向,能够解决引线位置偏移等问题,达到准确形成的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]Hereinafter, a first embodiment of the present invention will be described in detail with reference to the accompanying drawings.

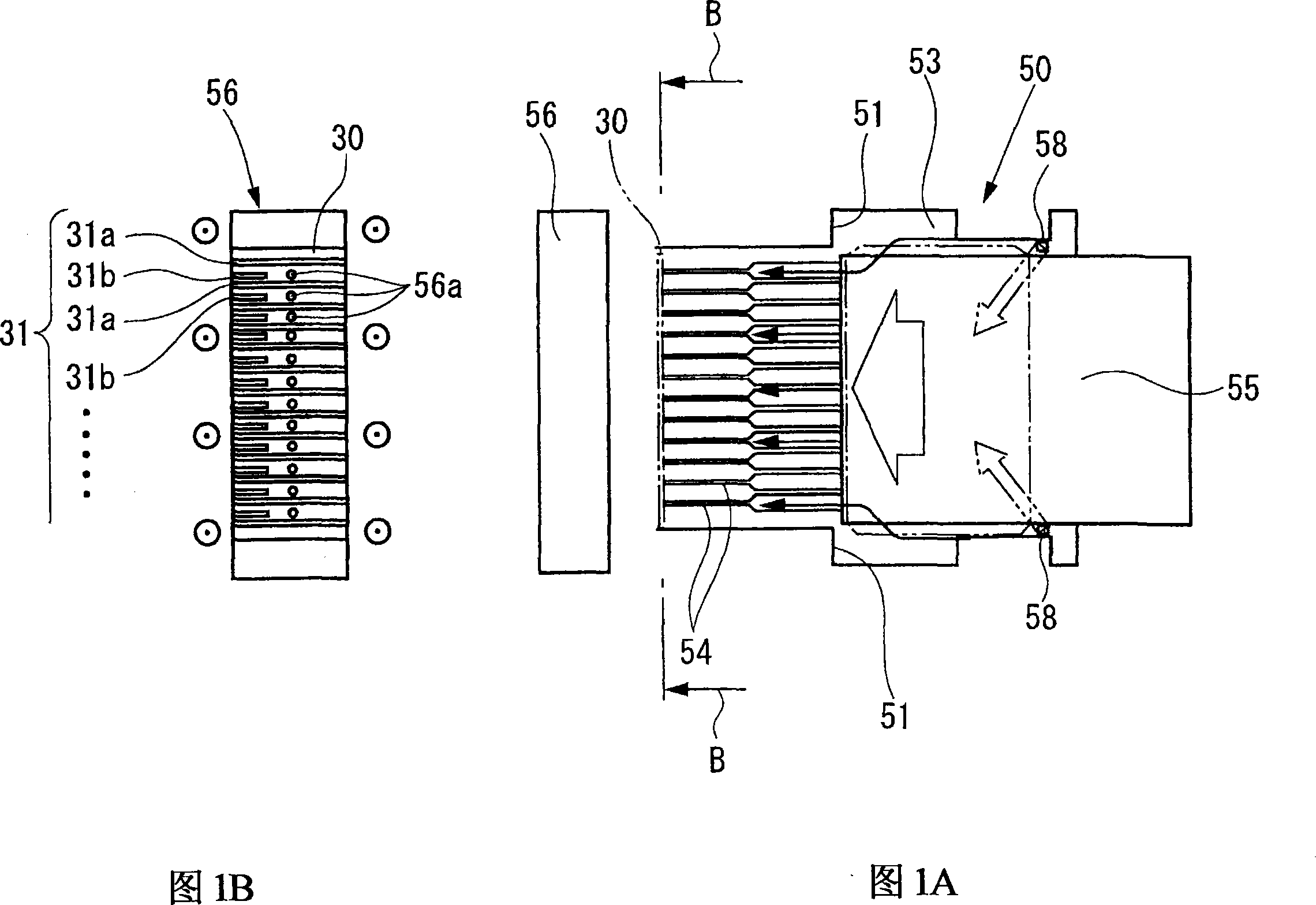

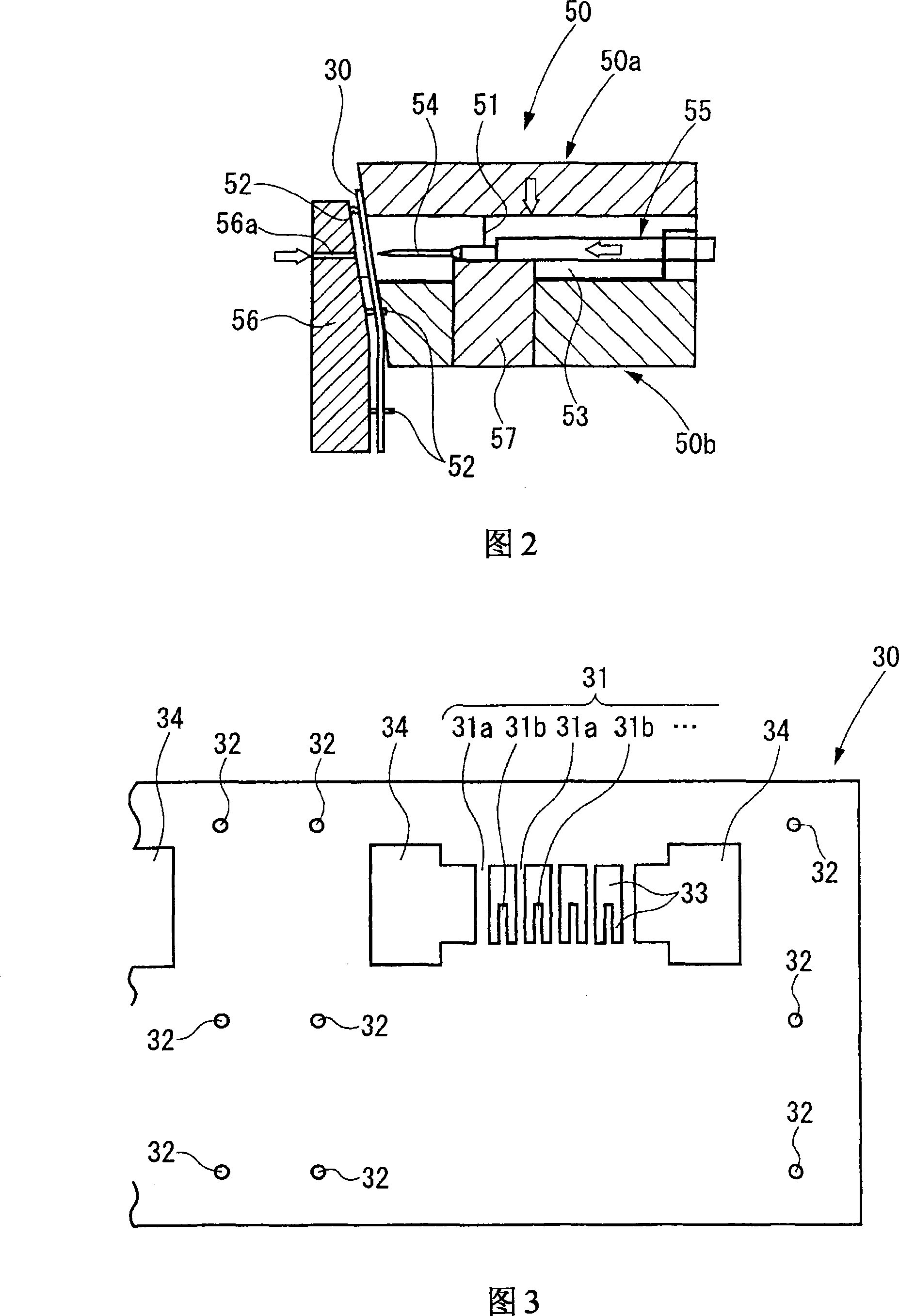

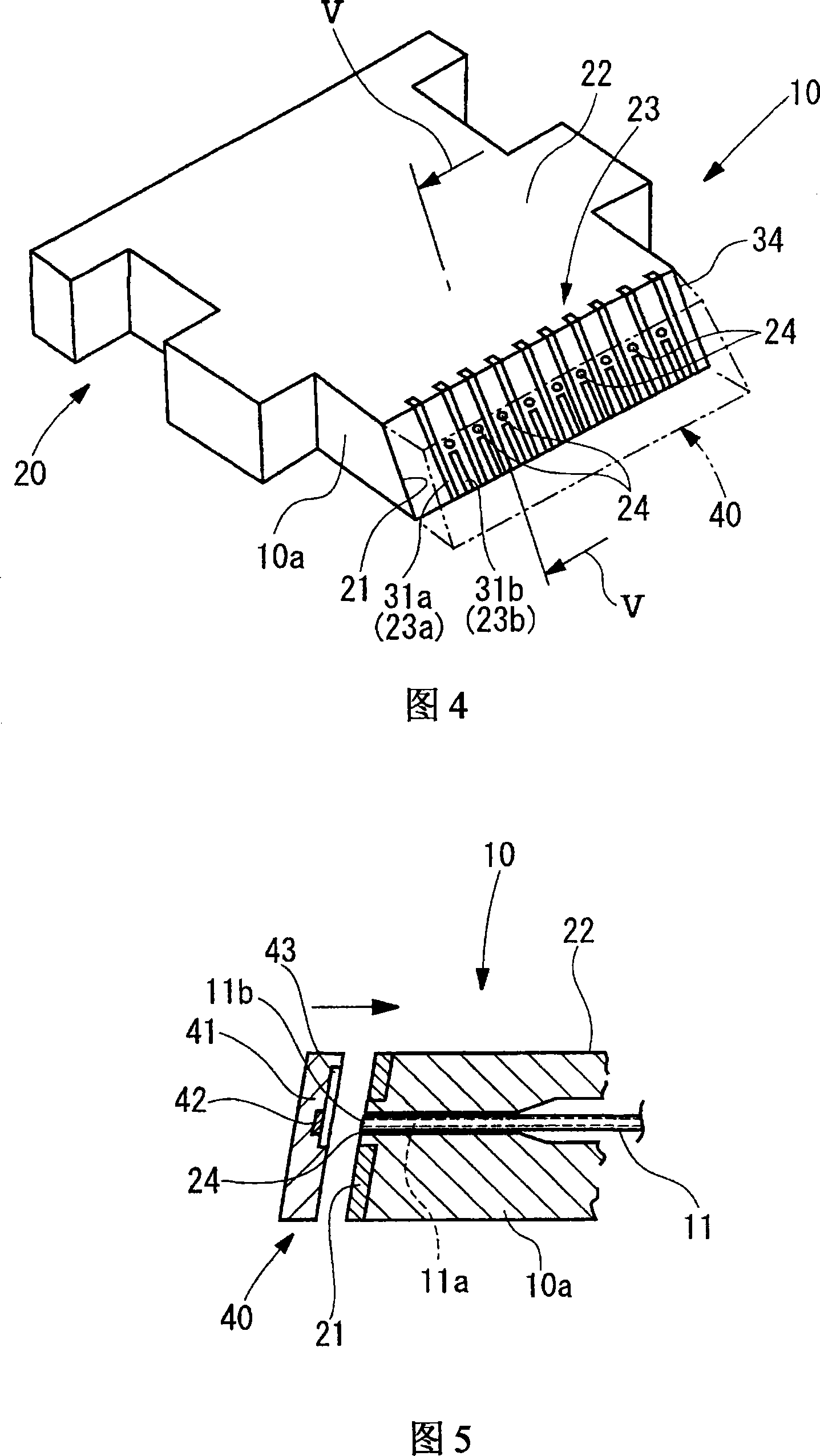

[0040] FIG. 1A is a plan view showing a first embodiment related to a method of manufacturing an optical fiber positioner according to the present invention. FIG. 1B is a cross-sectional view taken along line B-B in FIG. 1A. 2 is a sectional view showing an example of a mold used in the method of manufacturing an optical fiber positioner according to the present invention. FIG. 3 is a plan view showing an example of a lead frame. Fig. 4 is a perspective view showing an example of a fiber positioner. FIG. 5 is a cross-sectional view taken along line V-V in FIG. 4 .

[0041] As shown in FIGS. 1A and 1B , the method of manufacturing an optical fiber positioner, that is, the first embodiment of the present invention is a method of manufacturing an optical fiber positioner 10 (see FIG. 4 ), in which a lead frame 30 (see FIG. 3 ) That is, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com