Pneumatic tire

A technology for pneumatic tires, tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0059] Next, other embodiments of the present invention will be described.

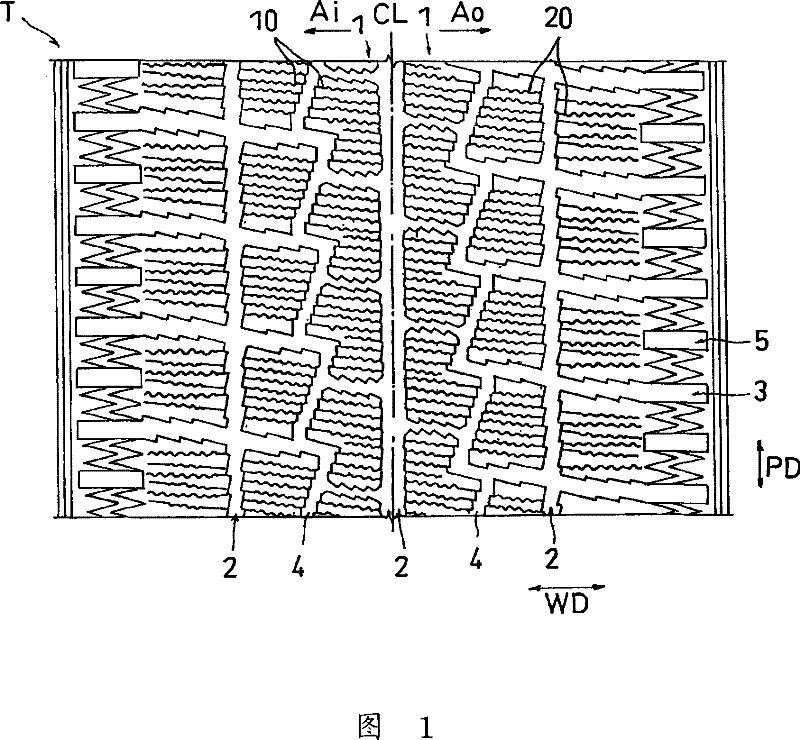

[0060] (1) Although the above-mentioned embodiment shows that the figure 1 The blocks of the shown shape are examples, but the blocks are not limited to this shape, and may be substantially square, parallelogram, V-shaped, pentagonal, or curved-based blocks. In addition, instead of the blocks, ribs extending linearly in the tire circumferential direction, ribs extending zigzag in the tire circumferential direction, lugs, or the like may be formed.

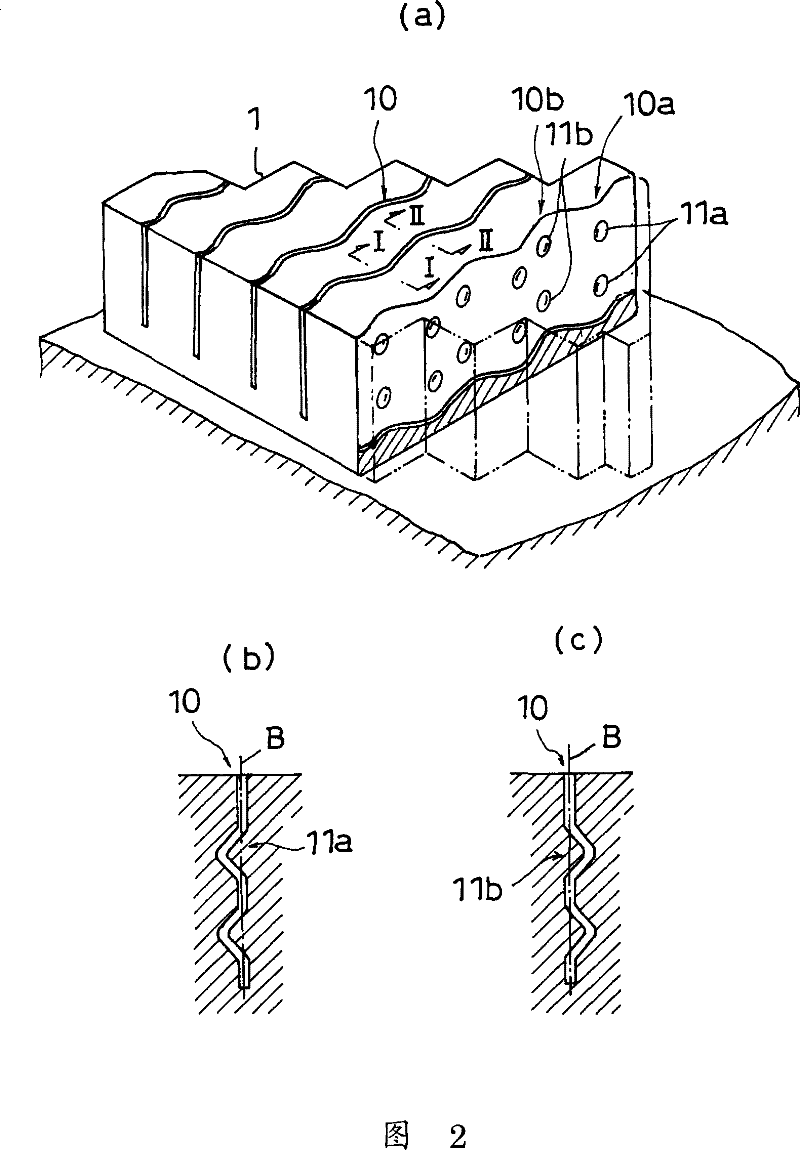

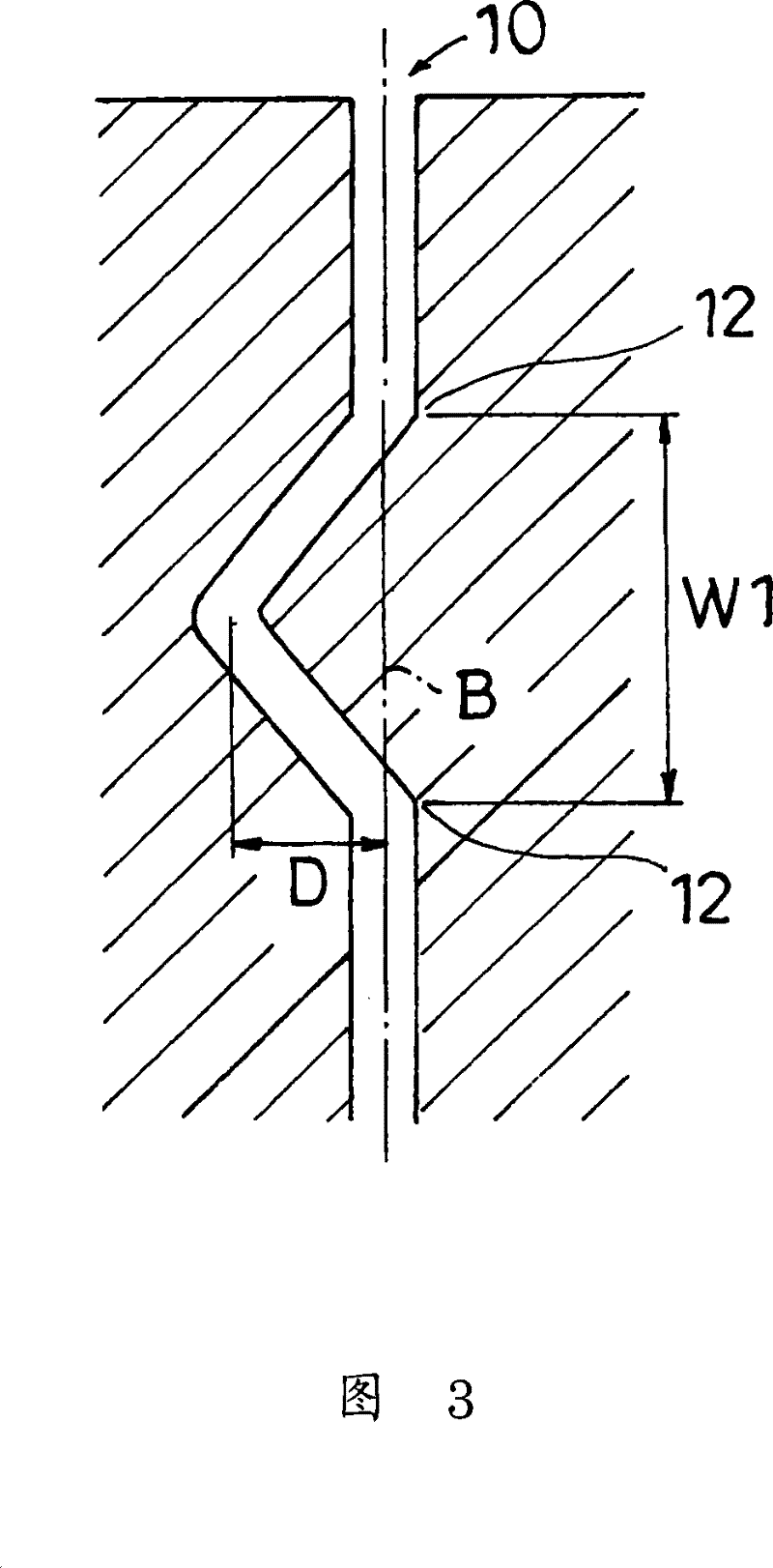

[0061] (2) Although the above embodiment shows an example in which multiple rows of sipe are formed toward the tire width direction, the formation direction of the sipe (central line direction) may be a direction inclined with respect to the tire width direction. However, from the viewpoint of both the turning performance and the braking performance of the tire, the angle between the sipe forming direction and the tire width direction is preferably 0±45°...

Embodiment

[0069] Next, examples and the like which specifically show the configuration and effects of the present invention will be described. In addition, each performance evaluation of the tire was performed as follows.

[0070] (1) Braking performance on icy and snowy roads

[0071] Install the tires on a real vehicle (3000cc class FR sedan produced in Japan), drive it on a frozen road with a load of 1 person, and apply braking force at a speed of 40km / h to activate the ABS. The index evaluation is based on the braking distance at this time. In addition, the evaluation is indicated by an index display when the conventional product (comparative example 1) is 100, and the larger the numerical value, the better the result.

[0072] (2) Turning performance on icy and snowy roads

[0073] The tire is mounted on the same actual vehicle as in (1) above, and it is driven on the same road surface with a double-button curve (8-shaped curve: a circle of R = 25m) under the load condition of o...

Embodiment 1

[0085] for figure 1 The tread pattern shown is formed in the area inside the mounting figure 2 The first sipe shown (same size as Comparative Example 2) is formed in the area outside the mounting Figure 5 The second sipe shown (the size is the same as that of Comparative Example 3) was used to produce a radial tire with a specification of 205 / 65R15. Table 1 shows the results of the performance evaluations described above using this tire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com