Shear type hoisting device

A scissor type, bottom plate technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of large lifting height, low lifting resolution, large driving force, etc., to achieve the effect of rapid lifting movement, ensuring flexibility, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

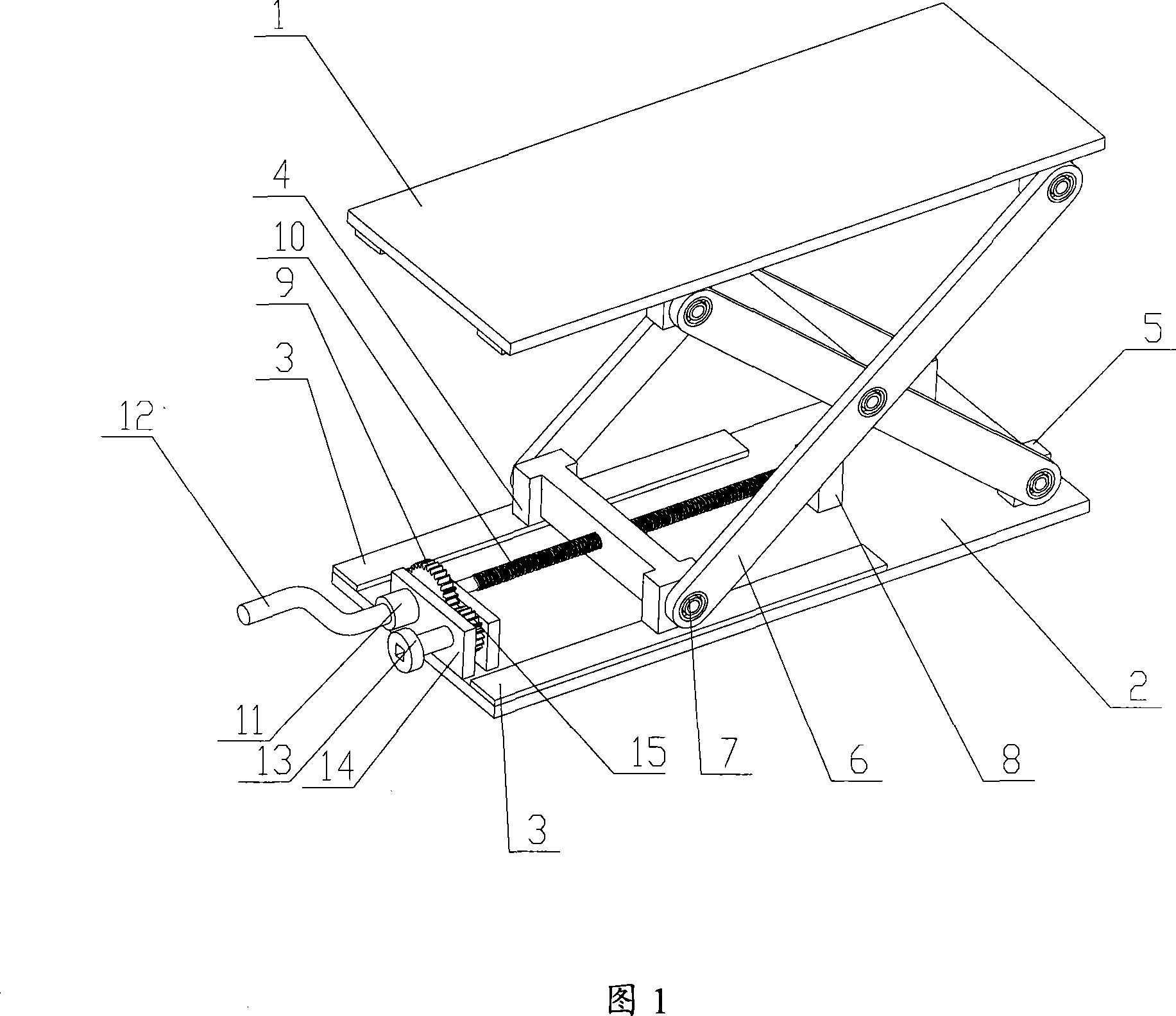

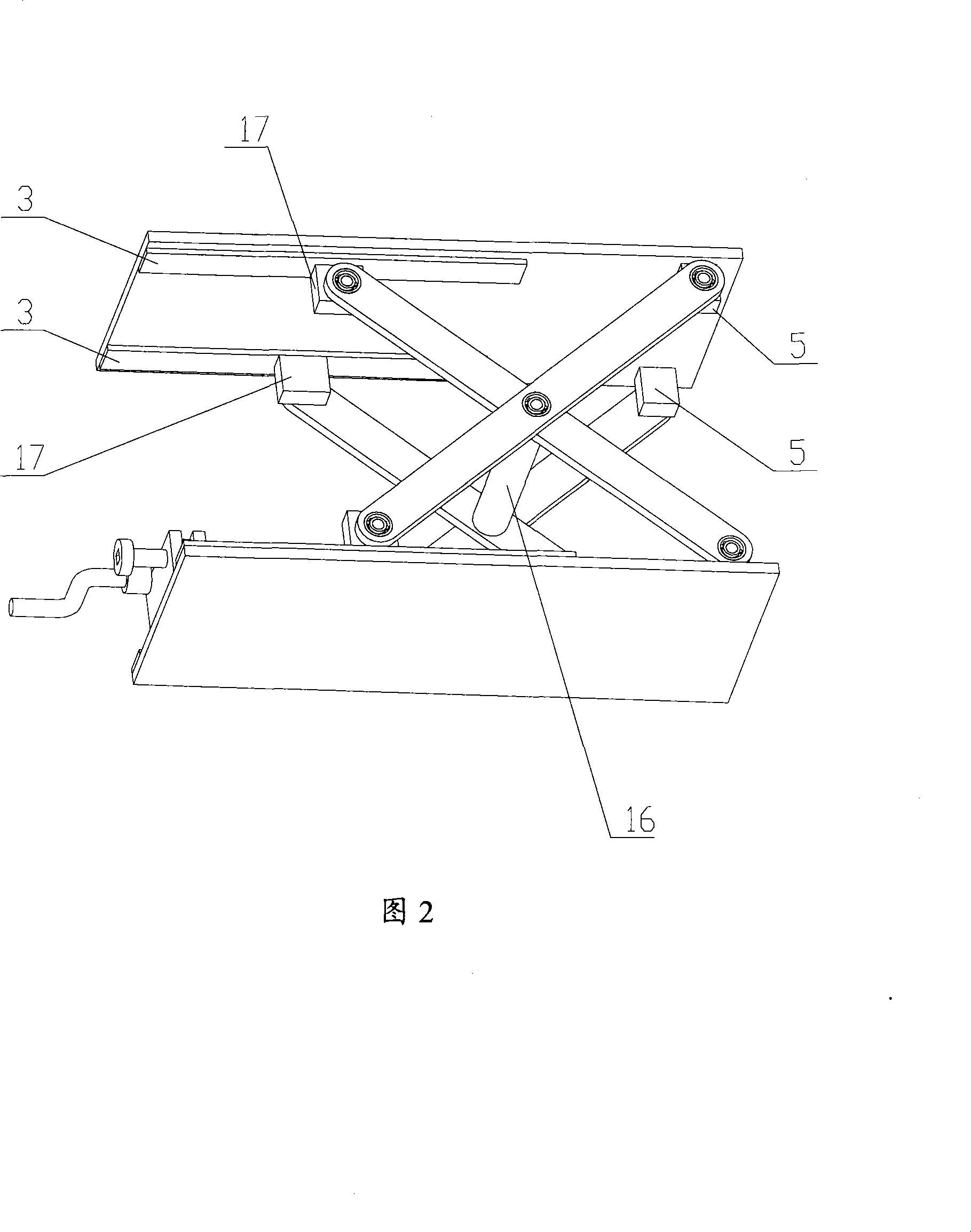

[0018] The scissor lifting device of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] 1 and 2, the present invention includes: bearing plate 1, bottom plate 2, guide rail 3, driving slider 4, fixed shaft seat 5, connecting rod 6, bearing 7, screw seat 8, large gear 9, screw 10 , Coarse adjustment knob 11, drive crank 12, fine adjustment knob 13, gear bracket plate 14, pinion 15, pin shaft 16, slide block 17.

[0020] The bearing plate 1 and the base plate 2 are connected by two sets of intersecting connecting rods 6 in an X shape, and four guide rails 3 are respectively installed on both sides of the bearing plate 1 and the base plate 2 in parallel along the longitudinal direction. The driving slider 4 is connected to the two ends of the two co-directional connecting rods 6 through the bearing 7, and can slide along the guide rail 3 on the bottom plate 2, and the slider 17 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com