Engine cooling system

An engine cooling and cooling channel technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve problems such as increasing engine warm-up time, heat loss, and increasing fuel consumption, reducing heat loss, realizing easy, Design a simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

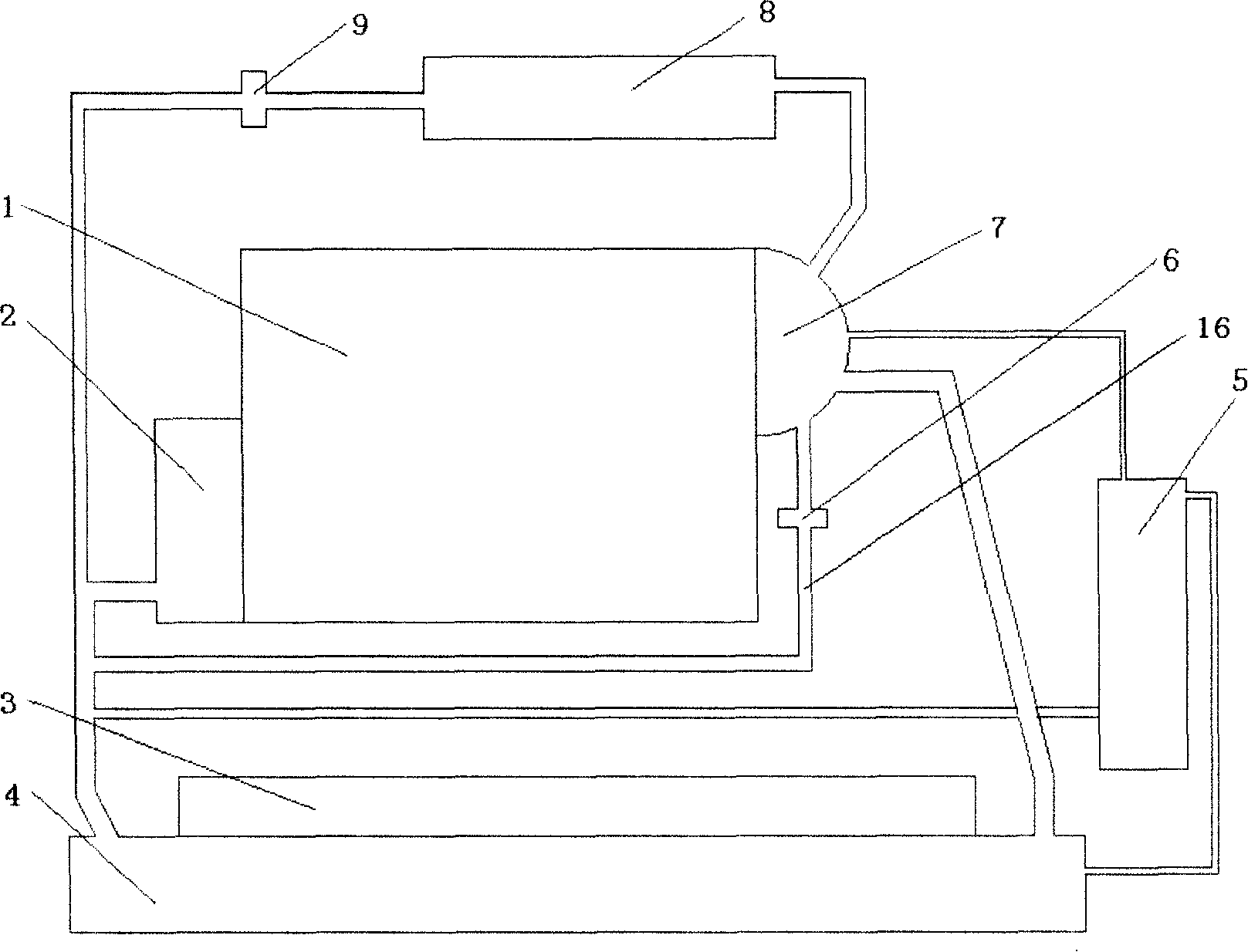

[0015] Example 1 in figure 1 Among them, an engine cooling system mainly includes an engine body water jacket (1), a water pump (2), a radiator (4), a fan (3), a thermostat (7), an expansion tank (5), and a heater for cooling (8) and connecting pipelines; when the engine coolant rises to the set temperature, the main valve of the thermostat (7) is opened, the auxiliary valve is closed, and the water jacket of the engine body (1) and the thermostat (7), Expansion tank (5), radiator (4), water pump (2) pipeline connection and engine body water jacket (1) and thermostat (7), small circulation loop (16), heater radiator (8), The pipes of the water pump (2) are connected together to form a large circulation cooling channel; when the temperature of the engine coolant is lower than the set temperature, the main valve of the thermostat (7) is closed and the auxiliary valve is opened, and the water jacket (1) of the engine body and the thermostat device (7), small circulation circuit ...

Embodiment 2

[0016] Embodiment 2 A shut-off valve (6) with a temperature control function is set in the small circulation loop (16). When the temperature is lower than the set temperature, the shut-off valve is in an open state. When the temperature is higher than the set temperature, the shut-off valve body is off. All the other are with embodiment 1.

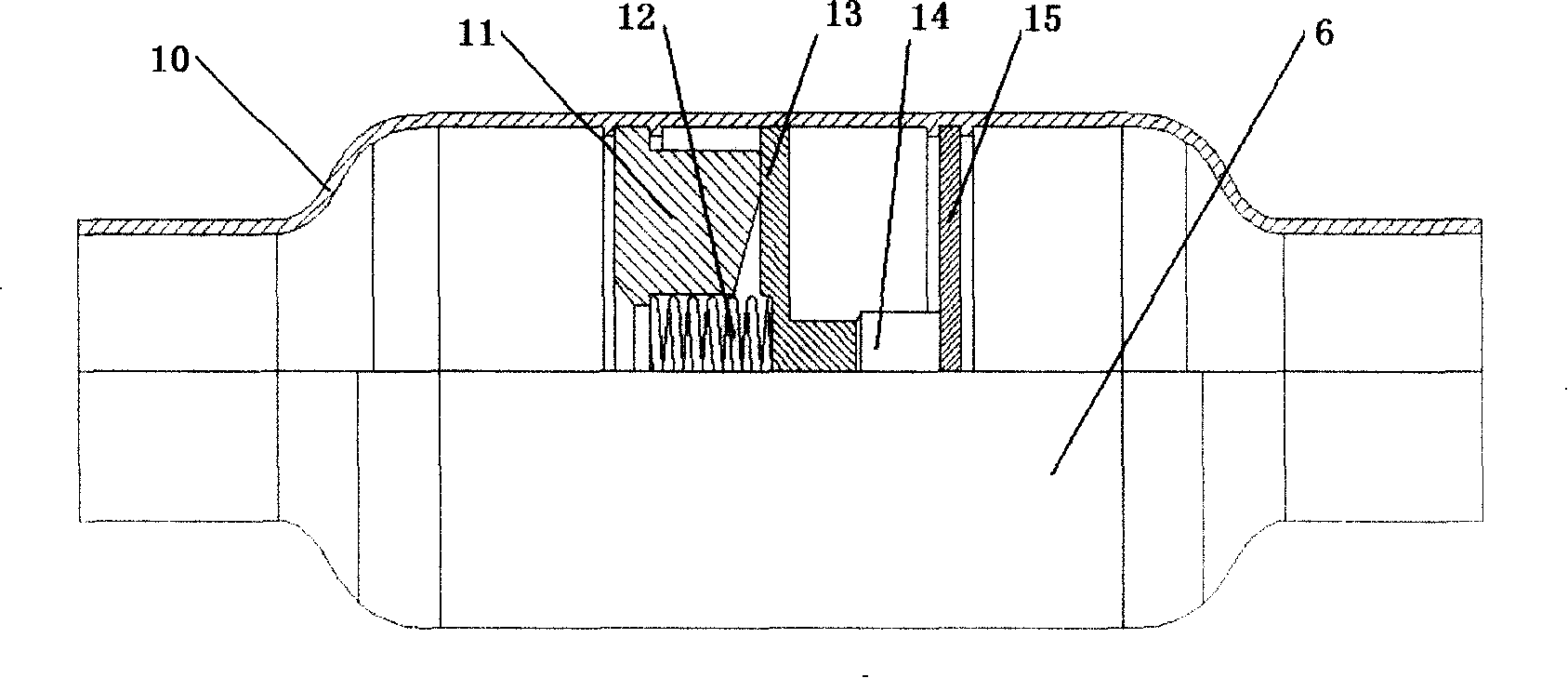

[0017] Above-mentioned shut-off valve body (16), as figure 2 As shown, it is mainly composed of a housing (10), a first fixed plate (11), a second fixed plate (15), a sliding plate and a push rod (13), a medium cavity (14), and a spring (12); The body (10) is fixed in the middle of the fixed disks (11, 15) at both ends of the inlet and outlet, and the spring (12), sliding disk and push rod (13), and the medium chamber (14) are connected in sequence; When the coolant temperature reaches the set temperature, the medium in the medium cavity (14) begins to expand, pushing the sliding plate and the push rod (13), and the linkage compresses t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com