Clip ring embedded jig

A snap ring and fixture technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., to achieve the effect of stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

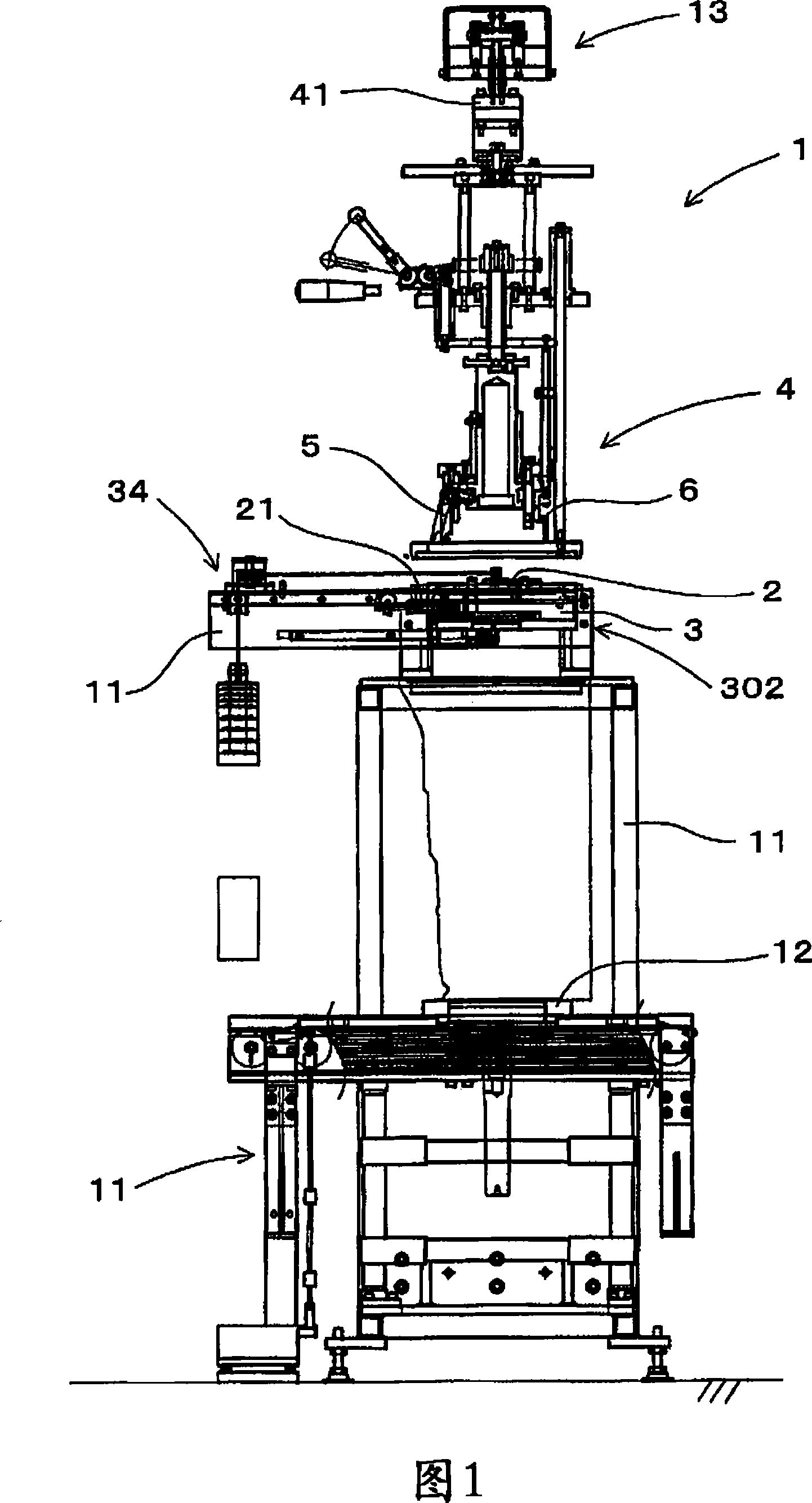

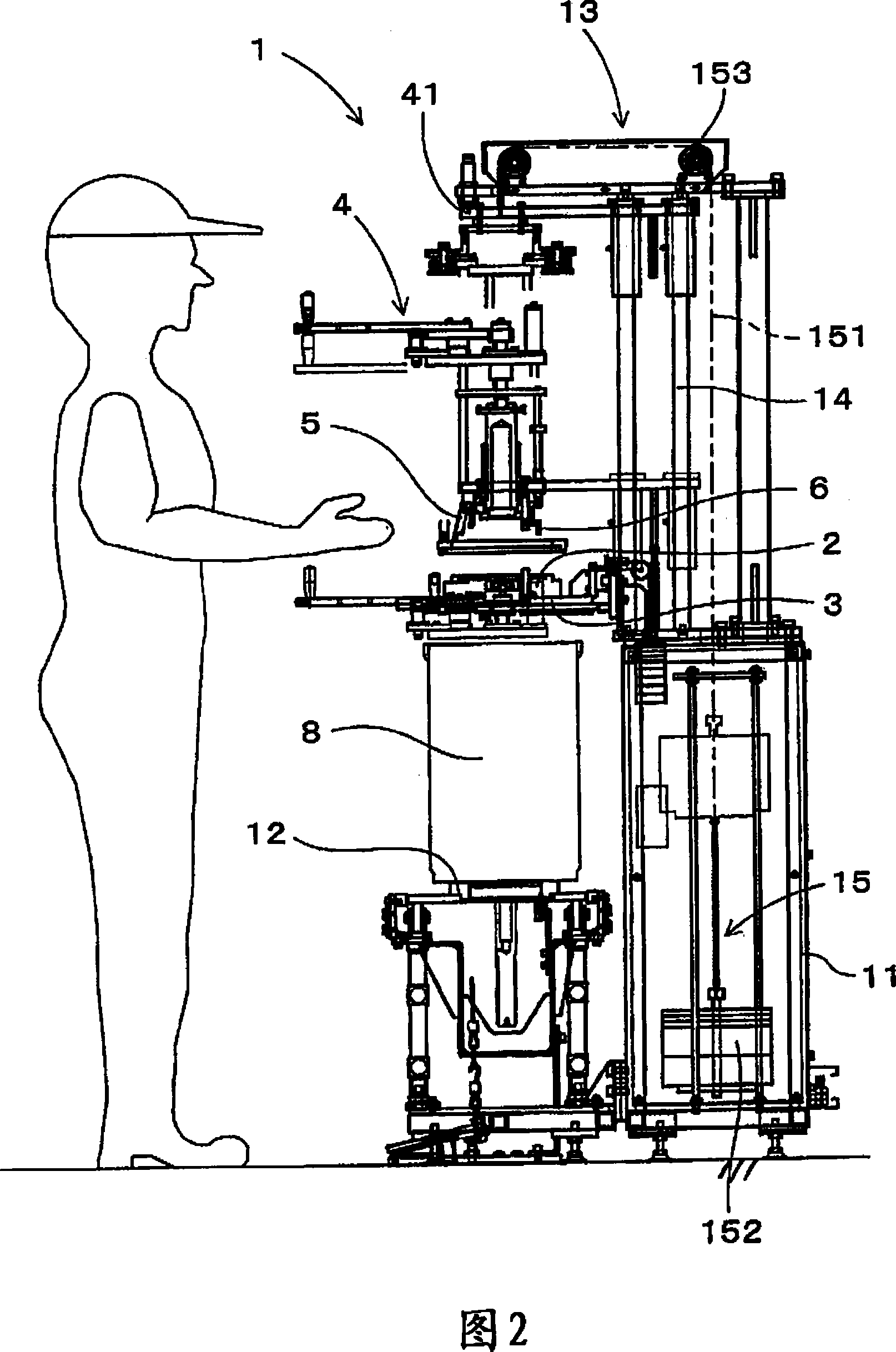

[0069] Next, the embodiment related to the jig for judging the front and back of the snap ring will be described in detail in conjunction with FIGS. 1 to 18 and 29 .

[0070] As shown in Fig. 1 and Fig. 8 to Fig. 12, the snap ring front and back judging jig 2 of this example is a jig for judging the front and back of the snap ring 9 when the snap ring 9 is handed over to the snap ring inserting jig 4. In addition, the snap ring fitting jig 4 is also a jig for fitting the snap ring 9 into the component to be assembled 8 .

[0071] As shown in Fig. 4 and Fig. 5, the snap ring 9 of this example has a C-shape with a notch 91 on a part of its circumference, the end surface 901 on one side in the axial direction is a vertical surface, and the end surface 901 on the other side in the axial direction is vertical. 902 has a sloped portion 92 . The slope portion 92 is formed to incline so that the thickness of the snap ring 9 decreases radially outward. In addition, at both end portio...

Embodiment 2

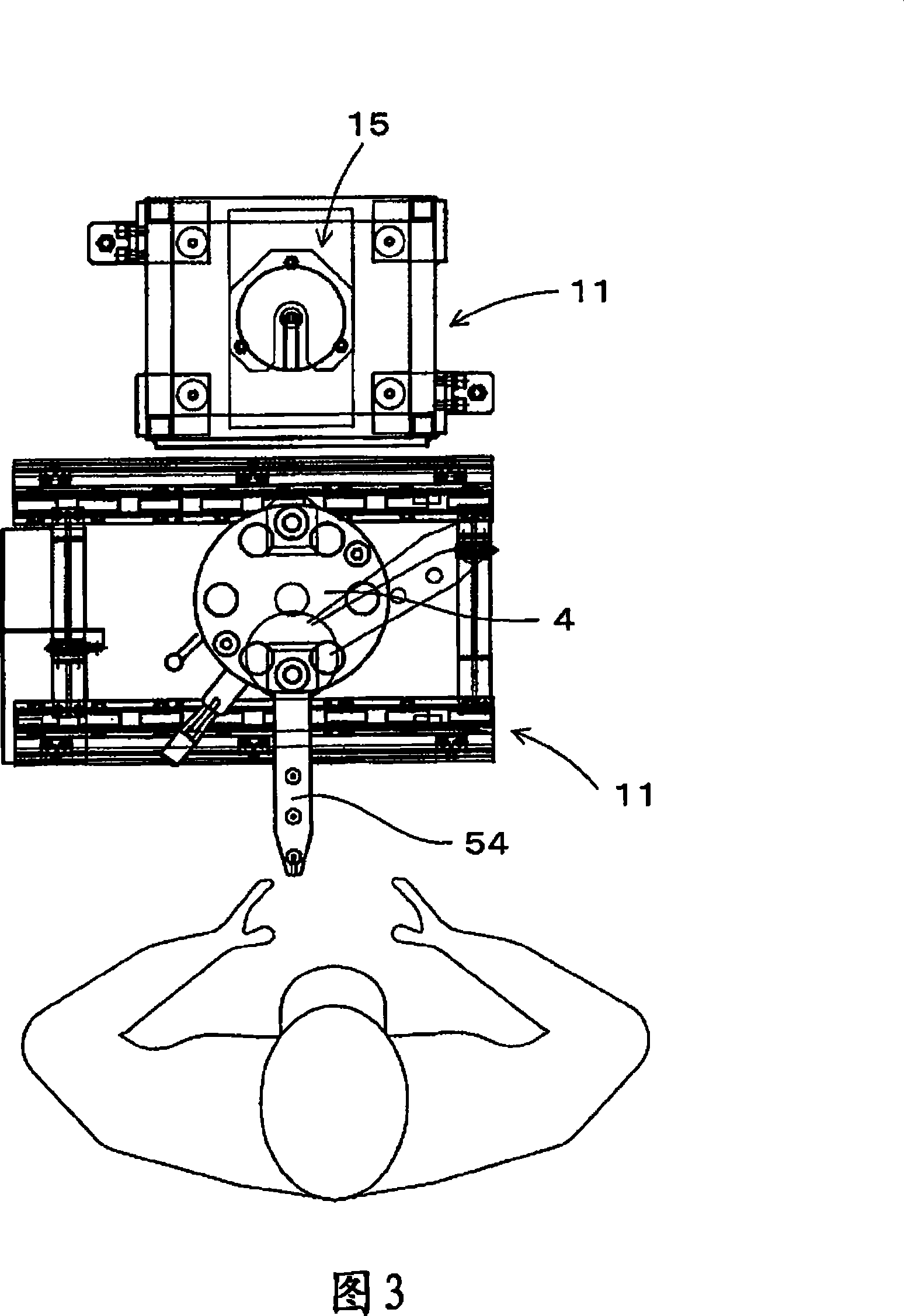

[0105] In this example, the above-mentioned snap ring fitting jig 4 will be described with reference to FIGS. 19 to 29 in particular.

[0106] As shown in Fig. 1 and Fig. 19 to Fig. 22, the snap ring fitting fixture 4 of this example is used to be inserted into the ring groove 82 formed in the circumferential direction in the assembling hole 81 of the assembled part 8, and has a The notch 91 is a clamp for the C-shaped snap ring 9 . In the assembly hole 81 of the component to be assembled 8 of this example, along the depth direction perpendicular to the peripheral direction of the assembly hole 81 , a plurality of depth direction grooves 83 in the circumferential direction of the assembly hole 81 are formed.

[0107] As shown in FIGS. 24 and 28 , the snap ring inserting jig 4 has a chuck portion 5 for clamping the outer periphery of the snap ring 9 and a push rod portion for pushing out the snap ring 9 clamped by the chuck portion 5 . 6. The chuck part 5 has a plurality of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com