Method of designing both-plane aspherical progressive refractive power lens group and both-plane aspherical progressive refractive power lens group

A technology of refractive index and lens group, applied in glasses/protective glasses, glasses/goggles, optics, etc., can solve the problems of poor method efficiency and increased cost, and achieve the effect of wide field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

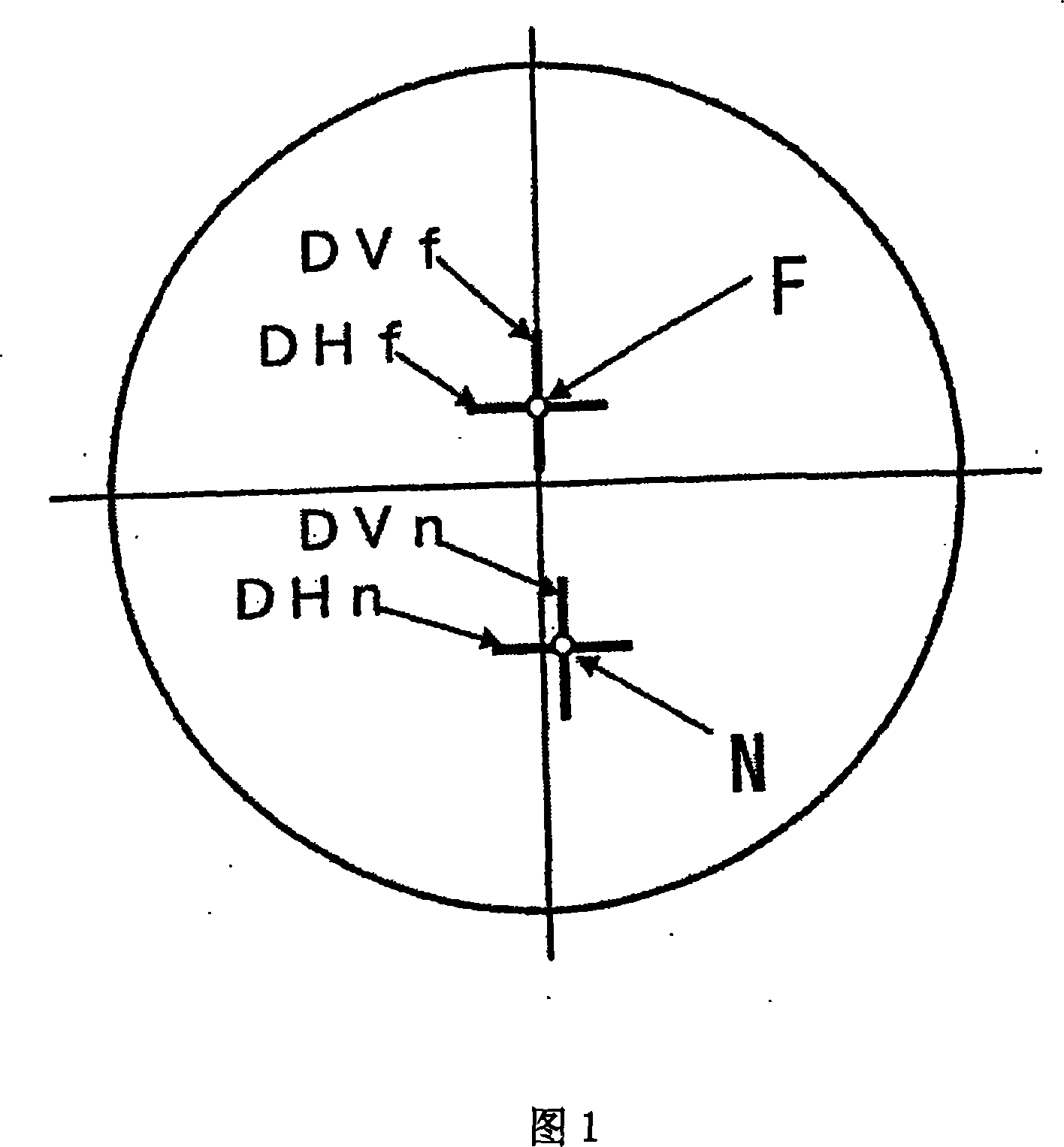

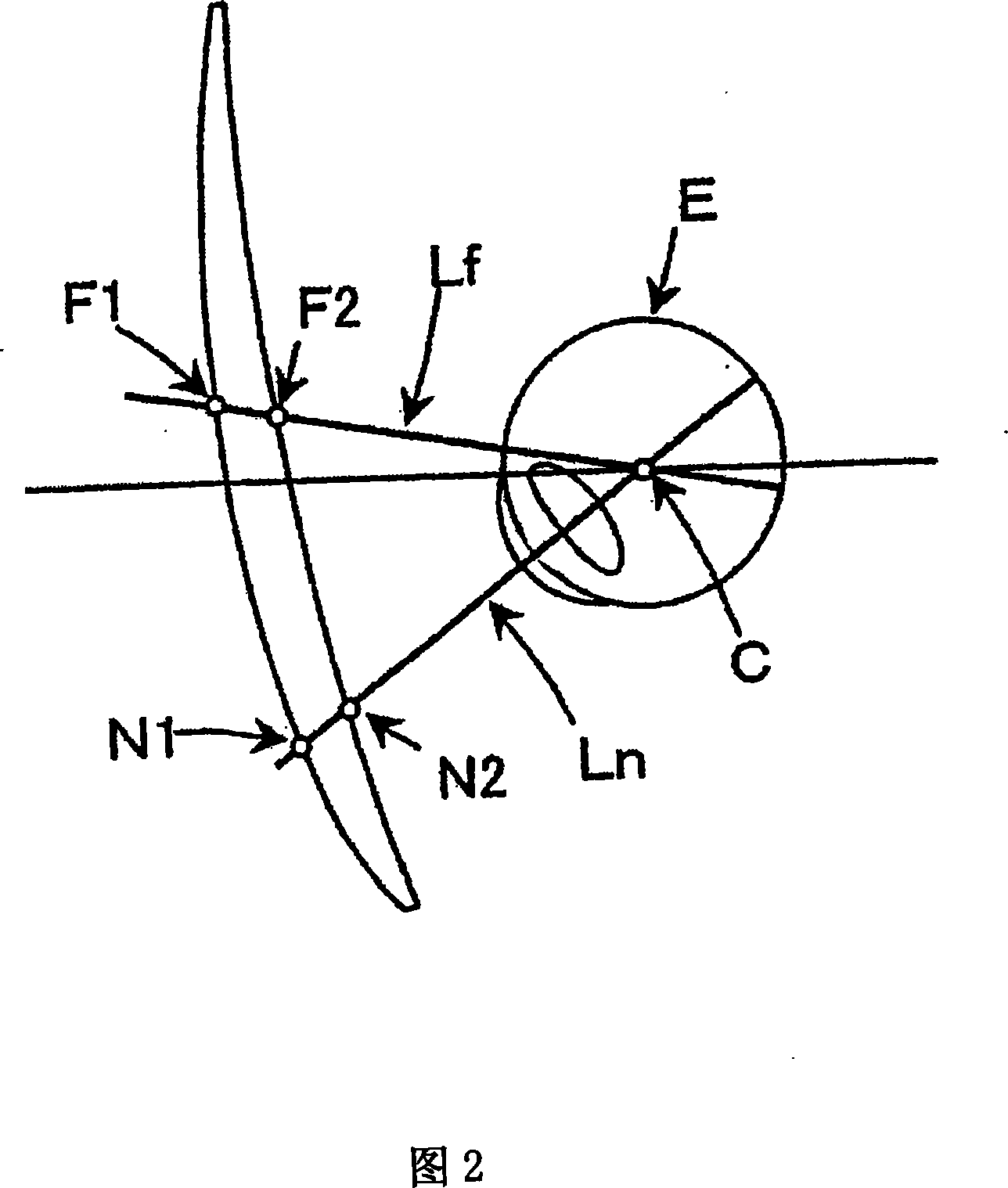

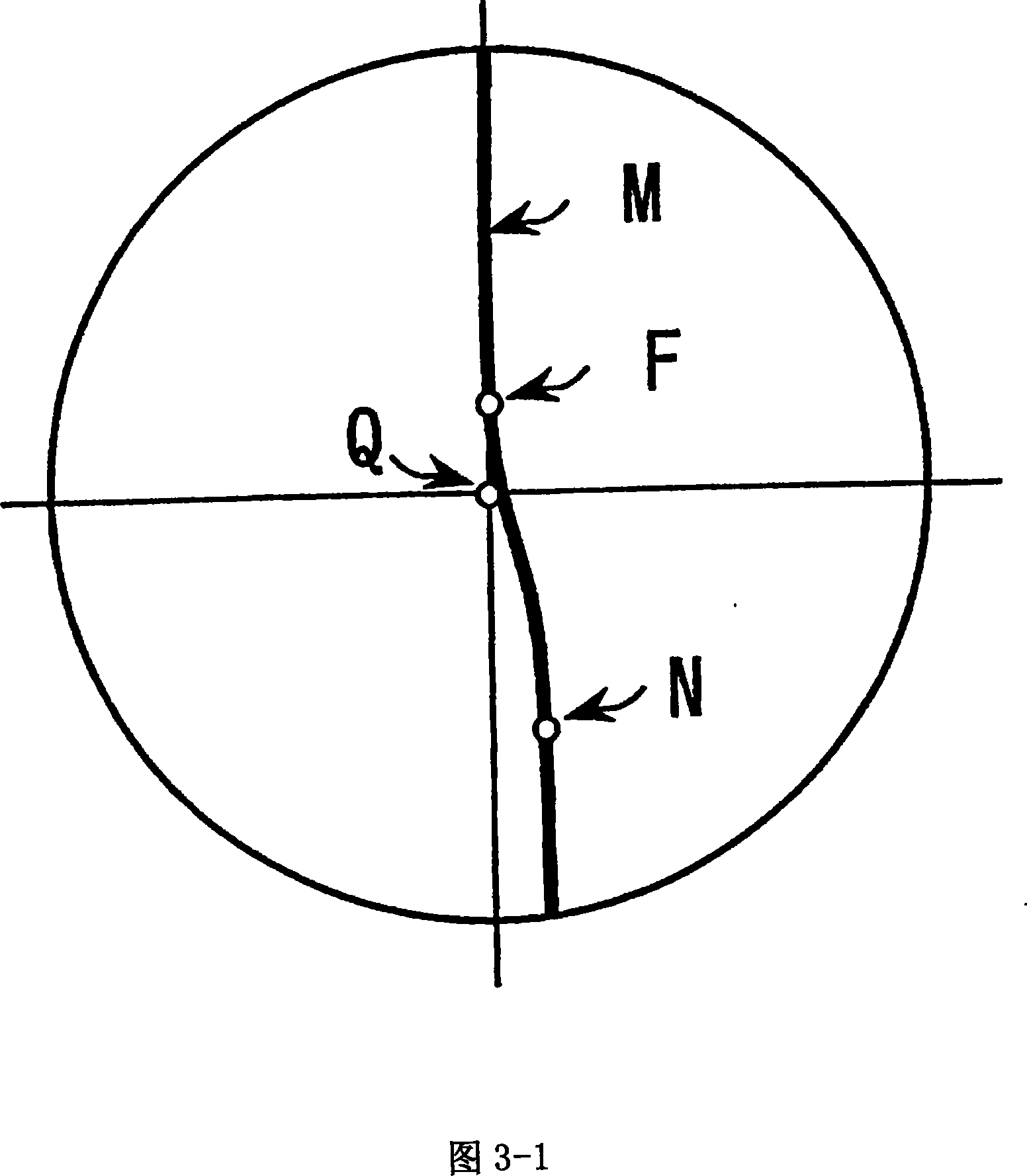

[0095] Figure 21 is a graph showing the list of Surface Refractive Index, Hyperopia Power, and Addition Power for Examples 1-4 (described below) in Tables 1-4, respectively. Tables 1-4 in FIG. 21 correspond to Examples 1-4 described below and are listings of surface refractive index, hyperopic power, and add-on power. The meanings of the items appearing in Table 1-4 are as follows:

[0096] DVf1: the surface refractive index on the object side surface in the vertical direction at the farsighted power measurement position F1;

[0097] DHf1: the surface refraction index in the horizontal direction at the distance measurement position F1 on the object side surface;

[0098] DVn1: the surface refraction index on the vertical direction at the myopia power measurement position N1 place on the object side surface;

[0099] DHn: the surface refractive index in the horizontal direction at the myopia measurement position N1 on the object side surface;

[0100] DVf2: the surface refra...

example 1

[0119] (Example 1-a, Example 1-b, Example 1-c, Example 1-d)

[0120] Table 1 and Figures 5-8 correspond to Example 1-a, Example 1-b, Example 1-c, and Example 1-d, respectively. These examples use the same object-side surface to provide different degrees of addition. It is understood that although the values of DVf1, DHf1, DVn1, and DHn1 in Table 1 are the same as each other, the ADD values are also different. The same applies to Figs. 5-8. The surface glitch at N1 is completely eliminated by the surface glitch at N2. For the degrees of myopia at N1 and N2, due to the difference in average refractive index between N1 and N2, different additional degrees are given, such as +1.00, +2.00, +3.00, +3.50; meanwhile, for F1 and Hyperopia at F2, the average refractive index difference between F1 and F2 is both 0.00.

example 2-a, example 2-b、 example 2-c、 example 2-d

[0122] Table 2 and Figures 9-12 correspond to Example 2-a, Example 2-b, Example 2-c, Example 2-d, respectively. These examples use the same object-side surface to provide different degrees of addition. It is understood that although the values of DVf1, DHf1, DVn1, and DHn1 in Table 2 are the same as each other, the ADD values are also different. The same applies to Figs. 9-12. The surface glitch at N1 is completely eliminated by the surface glitch at N2. Similarly, for hyperopia, the average refractive index difference between F1 and F2 is -1.00; for myopia, since the average refractive index difference between N1 and N2 is different, different additional degrees are given, such as + 1.00, +2.00, +3.00 and +3.50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com