Shock attenuation type tire

A tire and wheel technology, applied in tire parts, transportation and packaging, with multiple air chambers, etc., can solve problems such as affecting the performance and life of the vehicle, poor cushioning and shock absorption, and discomfort for passengers. Achieve the effect of improving the performance and life of the vehicle, good buffering and shock absorption, and large pressure bearing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

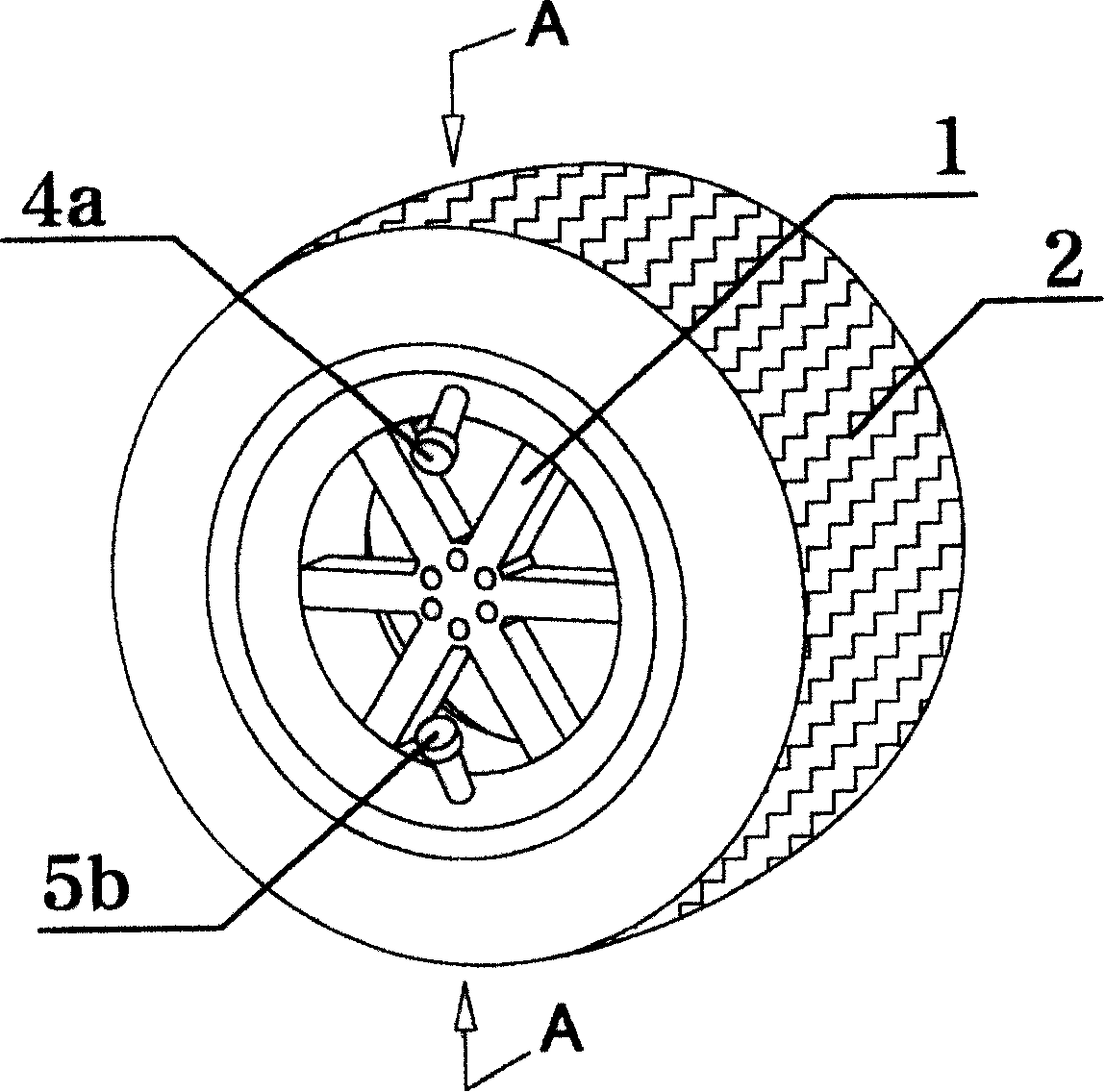

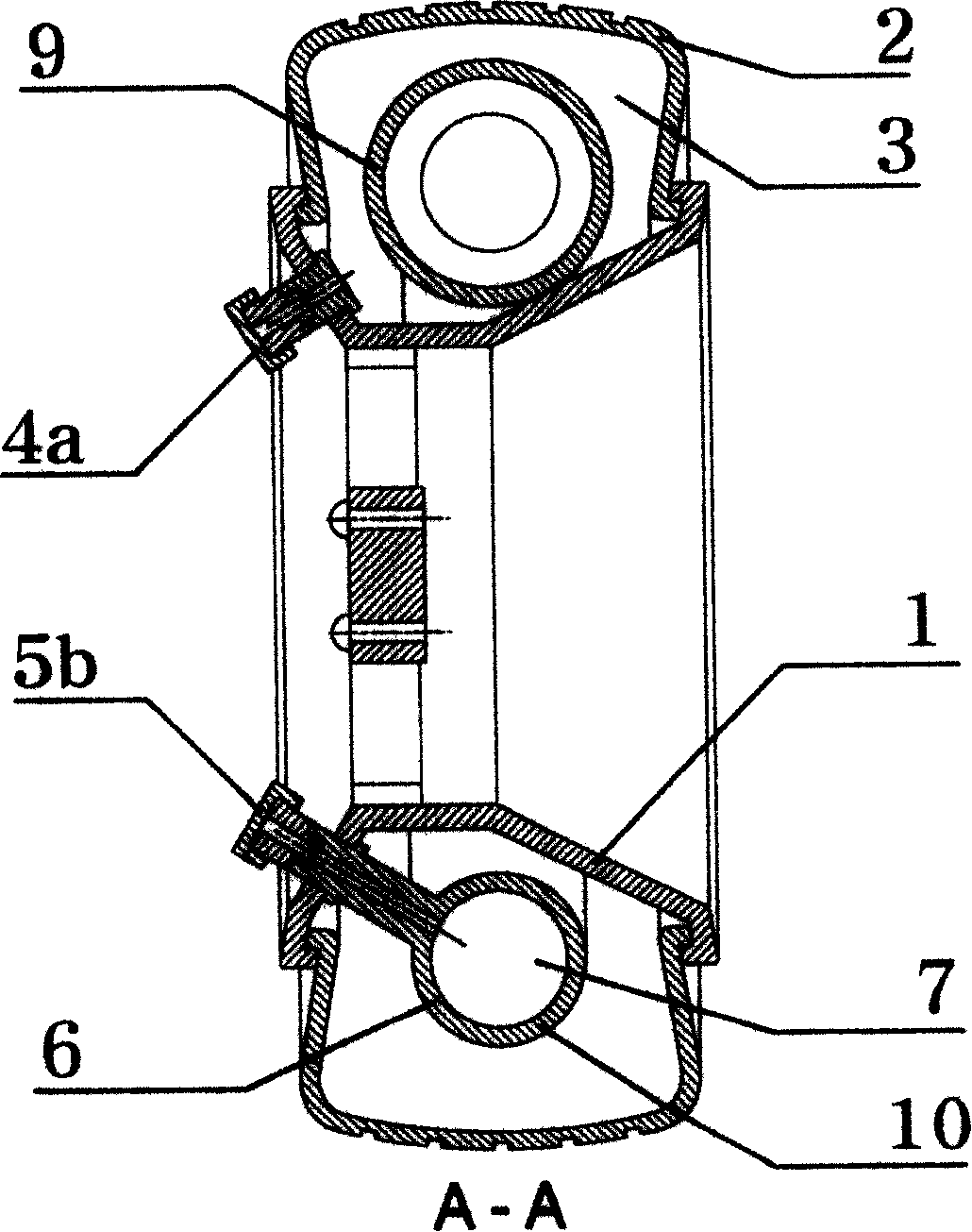

[0015] Embodiment 1: refer to figure 1 and 2 , the shock-absorbing tire of embodiment 1 is that cover tire 2 is sleeved on wheel hub 1, and the closed cavity of wheel hub 1 and cover tire 2 is outer inflation chamber 3, and the valve 4a that outer inflation chamber 3 is connected is fixed on wheel hub 1. An air bag 6 is arranged in the outer air chamber 3 , the closed cavity of the air bag 6 is an inner air chamber 7 , and the inner air chamber 7 is connected with the air valve 5 b, and the air valve 5 b is fixed on the wheel hub 1 . In the shock-absorbing tire of embodiment 1, because the air valves 4a, 5b are all fixed on the wheel hub 1, the airbag 6 is inflated after assembly. Cover tire 2 and air bag 6 all adopt rubber material usefulness mold molding.

Embodiment 2

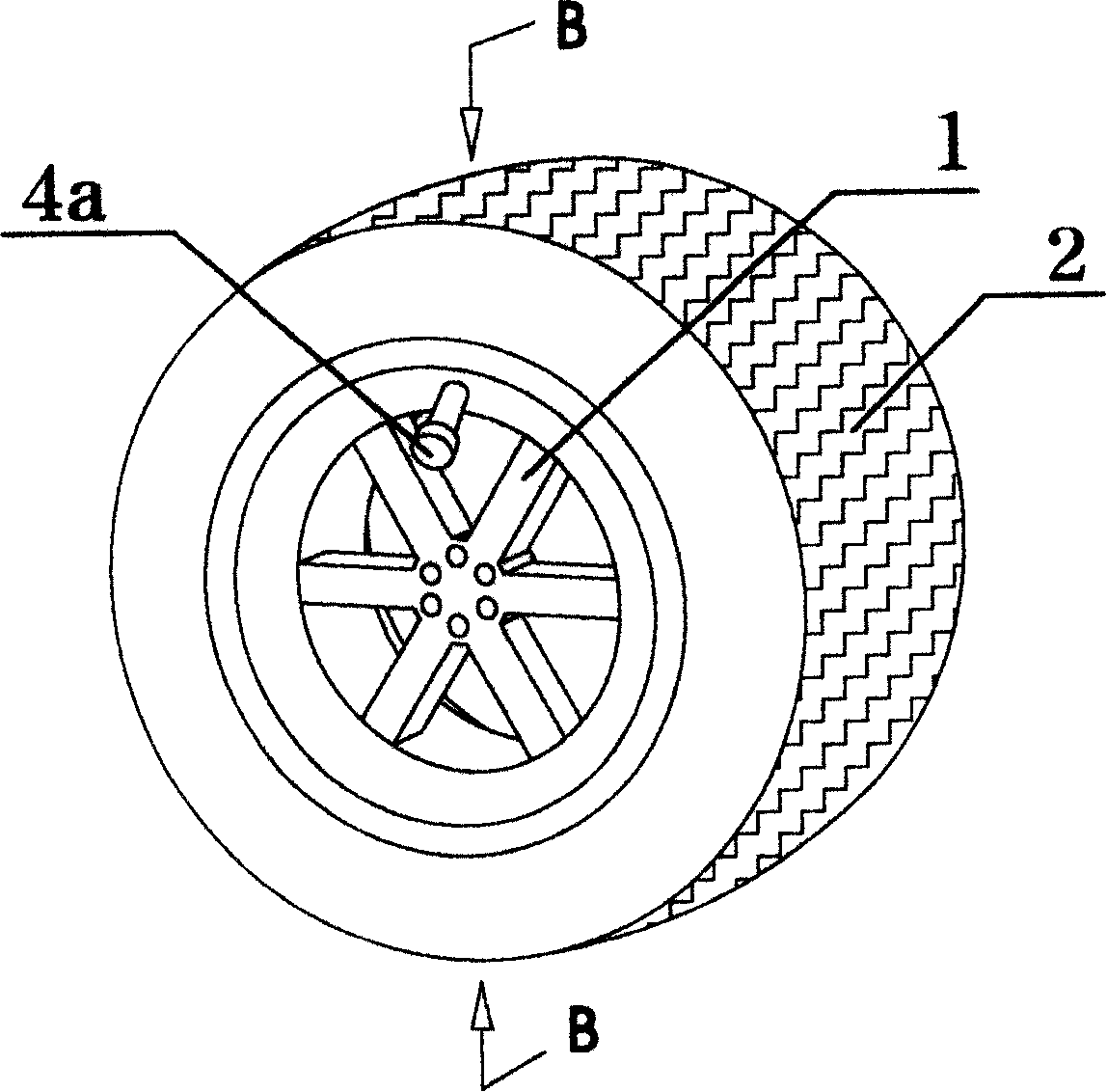

[0016] Embodiment 2: refer to image 3 and 4 , The shock-absorbing tire of Embodiment 2 is basically the same as Embodiment 1, the only difference is that the air valve 5b connected to the inner inflation chamber 7 is fixed on the air bag 6 . In the shock-absorbing tire of embodiment 2, because the air valve 5b is fixed on the air bag 6, it is necessary to inflate the air bag 6 before installing it in the outer inflation chamber 3.

[0017] refer to Figure 5 , the airbag 6 with the inner inflatable chamber 7 is composed of an airbag base 10 and several raised cavities 9 arranged thereon, the airbag base 10 of the airbag 6 and several raised cavities arranged thereon 9. The rubber material is integrally molded with a mold.

[0018] refer to Image 6 and 7 , the airbag 6 uses Figure 5 In addition to the closed integrated structure shown, a belt structure can also be used. When the belt structure is adopted, the two closed ends of the airbag 6 are connected by convex groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com