Demagnetizing device of electromagnet

An electromagnet and demagnetization technology, applied in circuits, magnetic objects, electrical components, etc., can solve the problems of restricting the output and quality of cement, unable to reset, easy to be magnetized, etc., to achieve the effect of improving labor production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

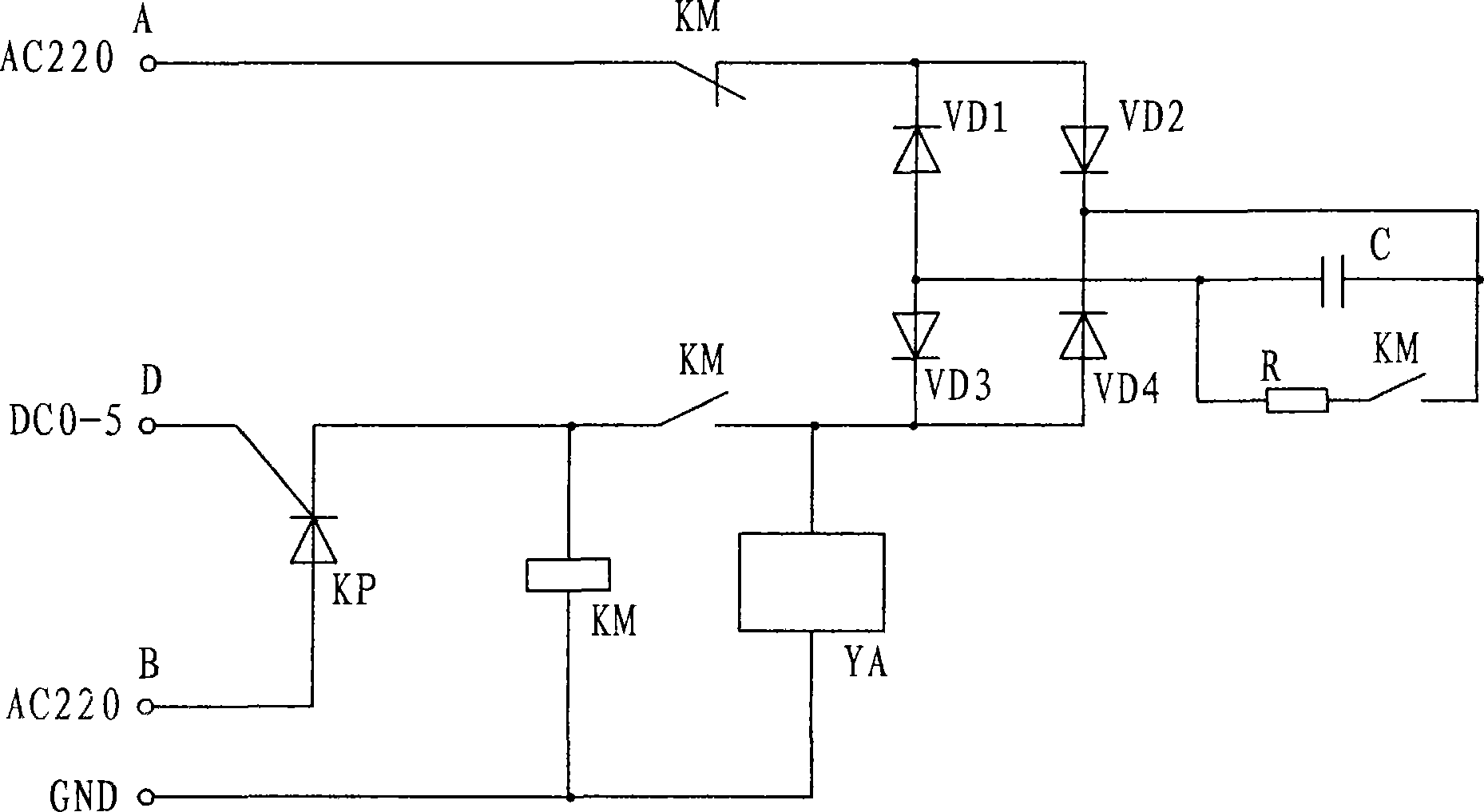

[0010] As shown in the accompanying drawings, the demagnetization device of the electromagnet includes a working iron core, an electromagnetic coil YA, and an electromagnetic coil work control circuit. The electromagnetic coil operation control circuit is connected in parallel, and the electromagnetic coil operation control circuit is electrically connected with a control relay KM for controlling the operation current or attenuation oscillation current of the electromagnet. The electromagnetic coil work control circuit includes a thyristor KP, an electromagnetic coil YA of a working core connected in series with the thyristor KP, and a thyristor conduction power supply DC; the current attenuation oscillating circuit includes a rectifier bridge VD1, VD2 , VD3, VD4, the output terminals of the rectifier bridges VD1, VD2, VD3, VD4 are electrically connected to a charging capacitor C, the charging capacitor C is connected in parallel with a discharge resistor R, and the discharge r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com