Method for preventing vulcanized rubber entering into jack

A technology of vulcanized rubber and jacks, which is applied to the parts of connection devices, the manufacture of contacts, and cable terminals, to achieve the effects of ensuring quality, prolonging service life, and improving electrical performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

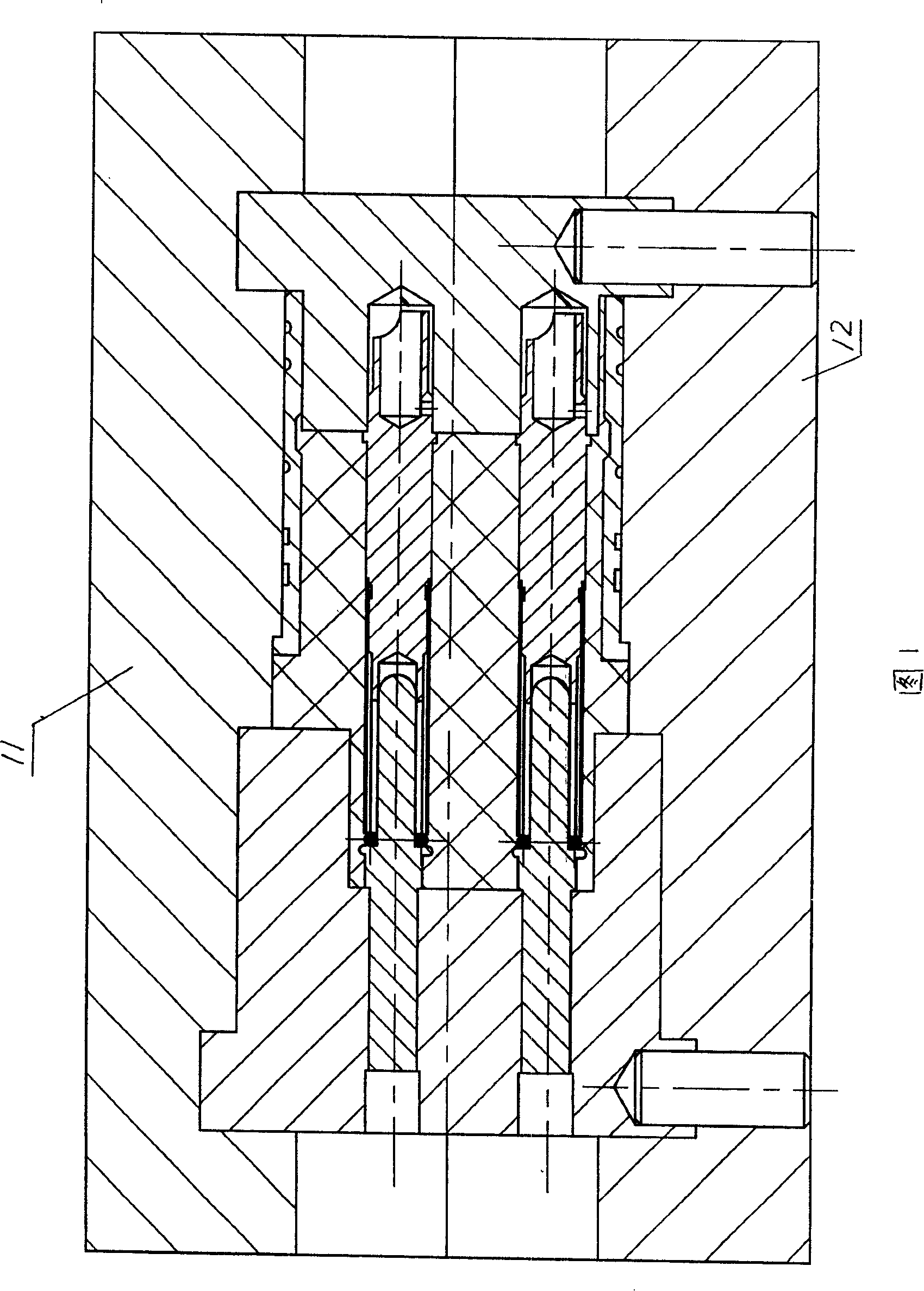

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0019] This embodiment takes the six-core plug used for underwater operations as an example to illustrate the method of preventing the vulcanized rubber from entering the socket during the vulcanization process, as follows:

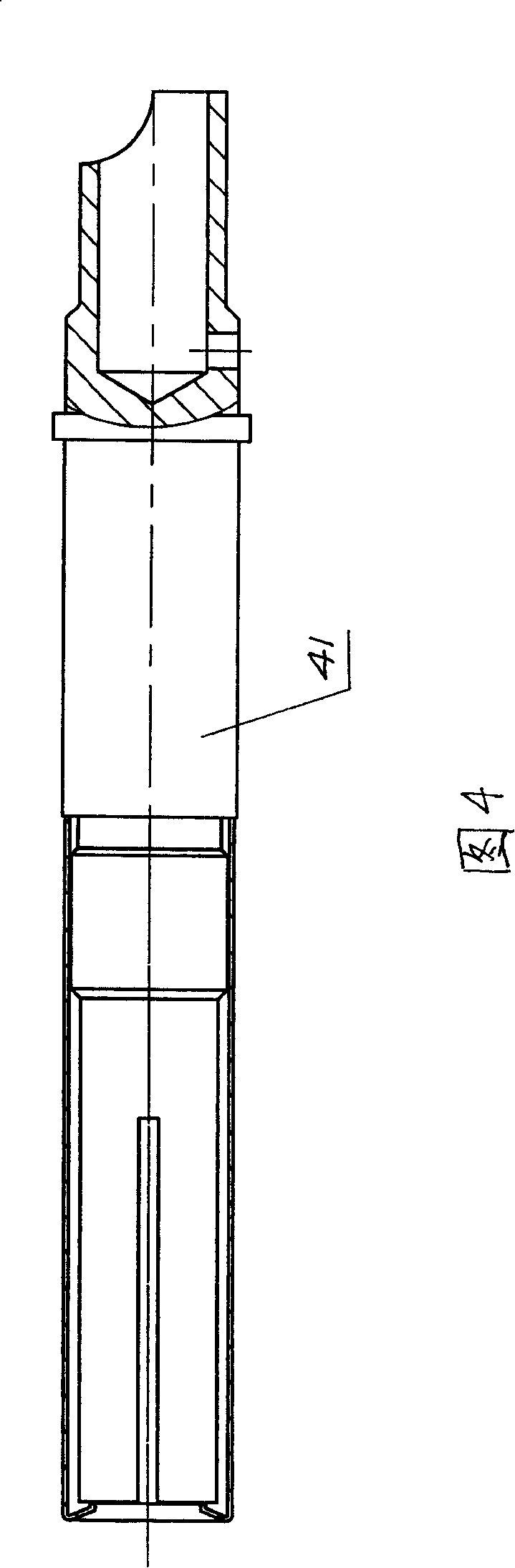

[0020] 1. First, ring the socket 41 (see FIG. 4 ) and the housing 51 (see FIG. 5 ), and then apply primer.

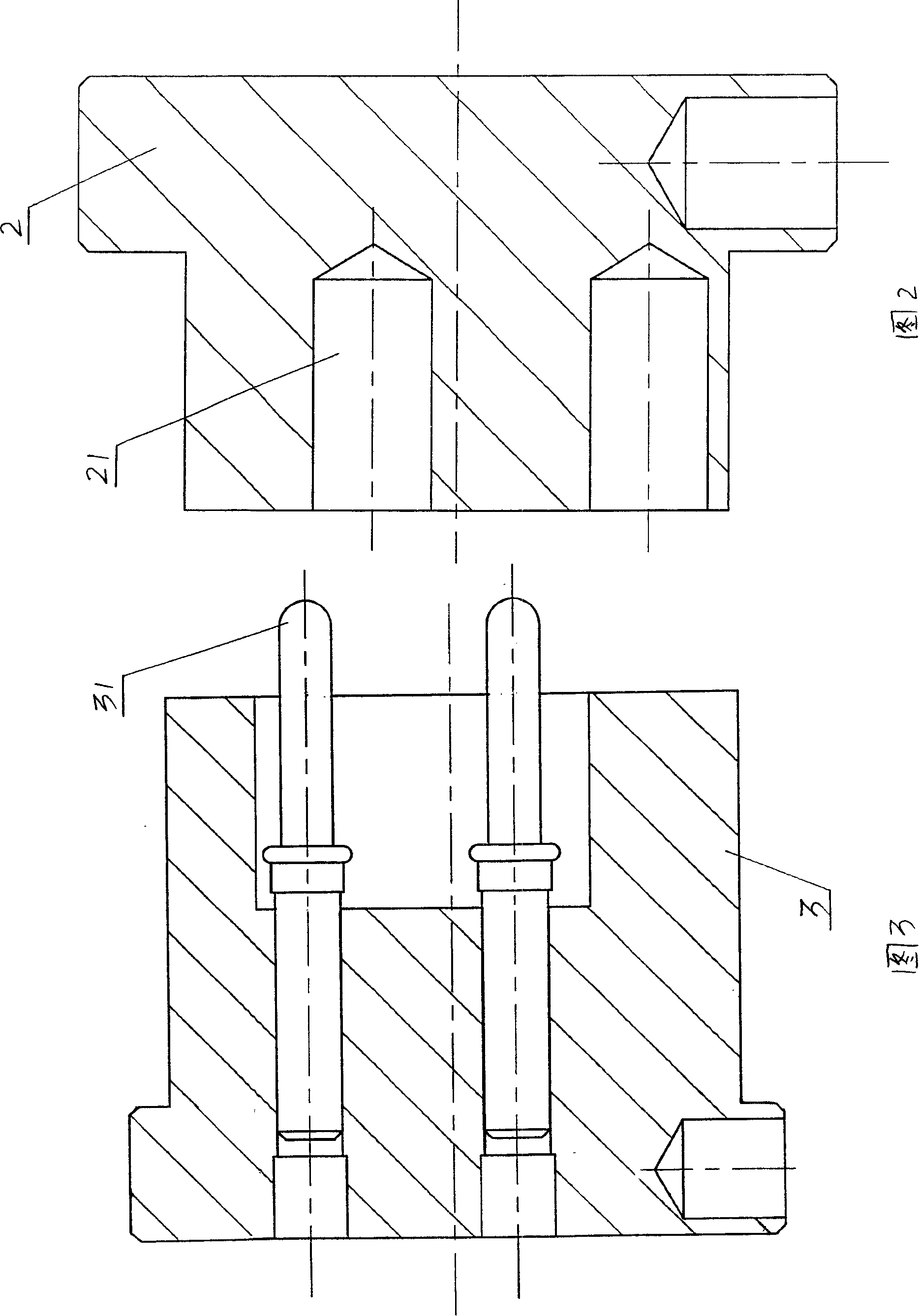

[0021] 2. Put 6 O-rings 61 (see Figure 6) into the bottom of the left mold core positioning pin 31 one by one (see Figure 3).

[0022] 3. Put the jacks 41 that have been aired into each hole of the right mold core jack 21 one by one (see Figure 2).

[0023] 4. Install the shell 51 (see FIG. 5 ) onto the right mold core 2 .

[0024] 5. Put the left mold core 3 and the right mold core 2 together, and tap them tightly with a small copper hammer, so that the socket 41 and the O-ring 61 (the material is rubber) are close without gaps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com