Extruder

A technology of extruder and barrel, which is applied in the field of polymer material processing machinery, can solve the problems of unfavorable gas discharge and glue leakage, etc., so as to improve production efficiency and profit, facilitate operation and use, and solve glue leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

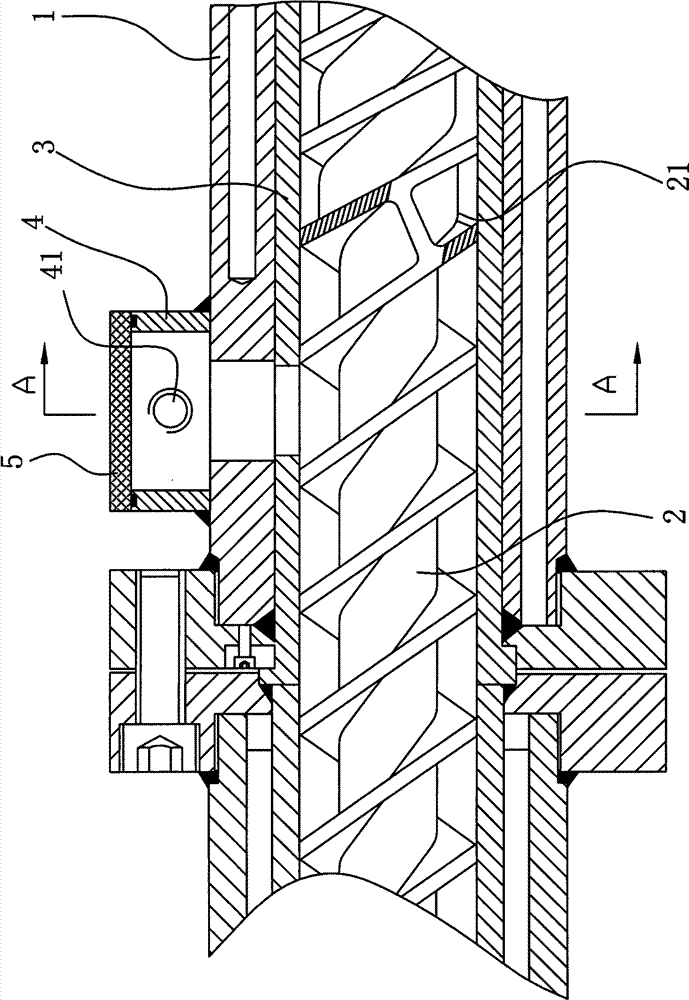

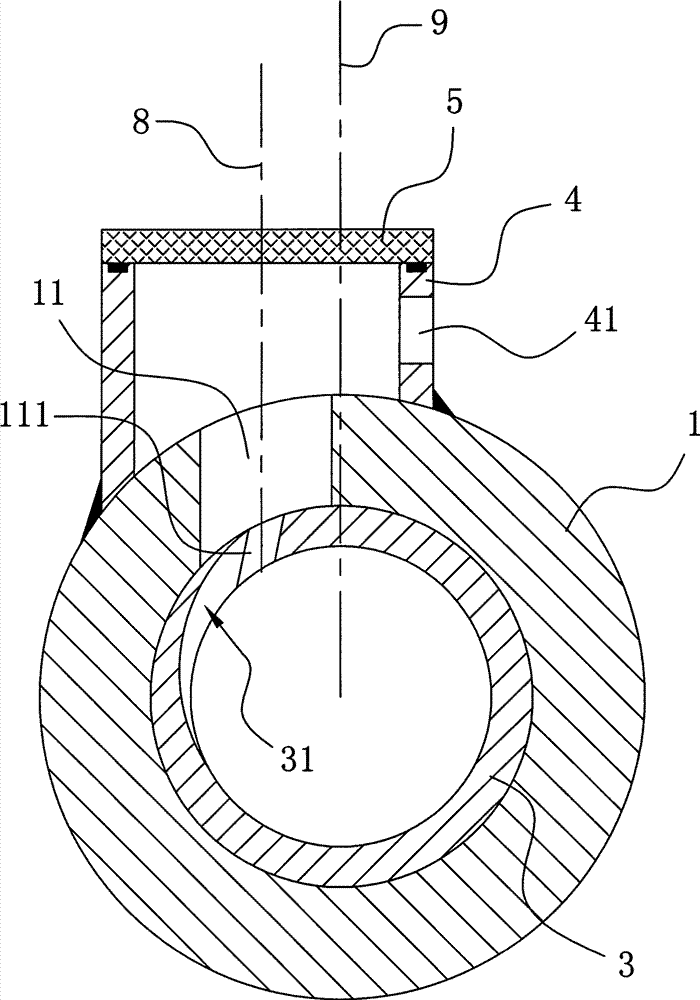

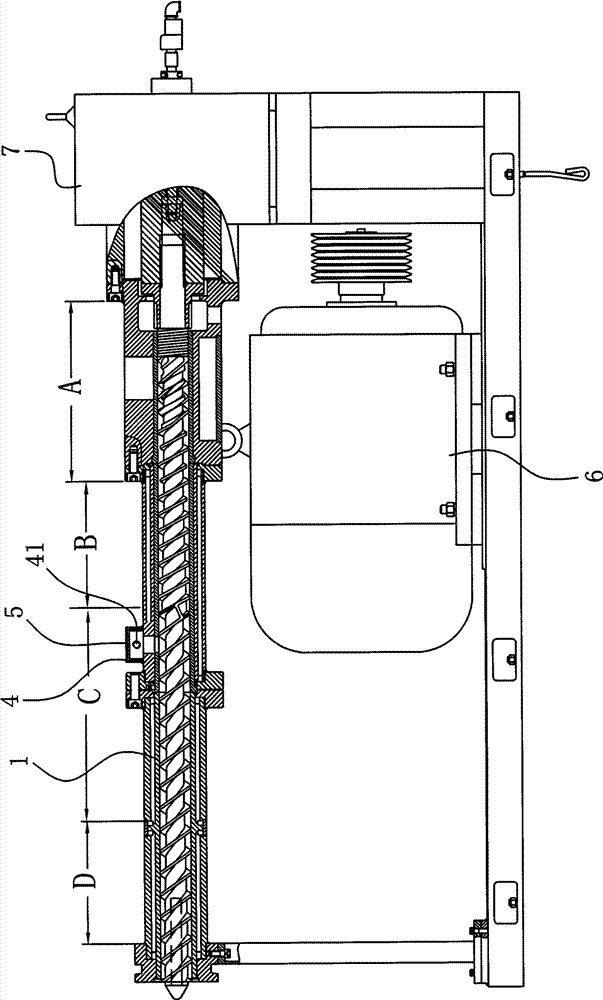

[0017] As shown in the figure, an extruder includes a barrel 1, a screw 2 and a transmission device 7. The transmission device 7 is linked with the output shaft of the motor 6 to drive the screw 2 to rotate. The feed port and the discharge port, the screw 2 is rotatably arranged in the inner cavity of the barrel 1, and is sequentially divided into a feed section A, a melting section B, a plasticizing section C and an extrusion section D; the machine The cylinder 1 is vertically provided with an air extraction port 11, the air extraction port 11 is a through hole with a small lower aperture and a large upper aperture, and the vertical center axis 8 of the air extraction port 11 is located at the center of the longitudinal axis 9 of the machine barrel 1. On one side; the inner wall of the barrel 1 is provided with a wear-resistant layer 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com