Special extrusion machine for producing edible conveying special monofilaments

A food-grade, extruder technology, which is applied in the field of monofilament production line equipment, can solve the problems of wasting raw materials, raw material waste, and rubber leakage, and achieve the effects of ensuring quality, avoiding waste of raw materials, and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

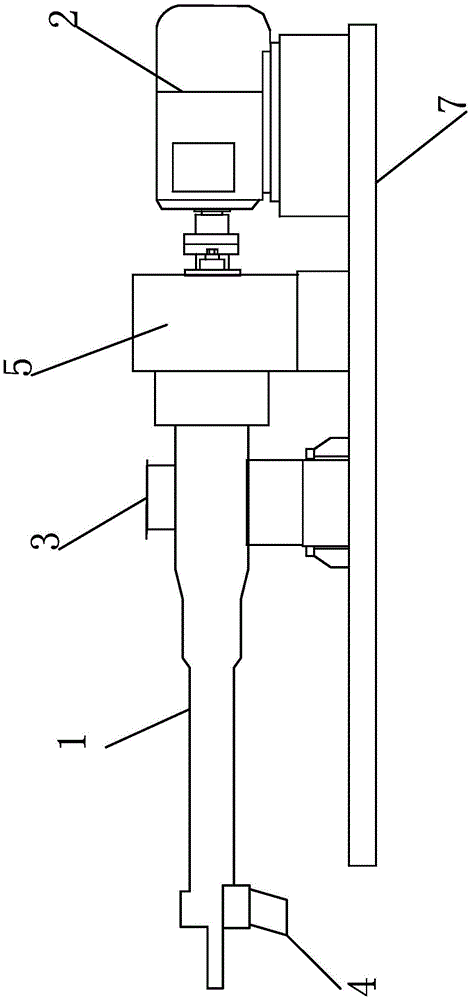

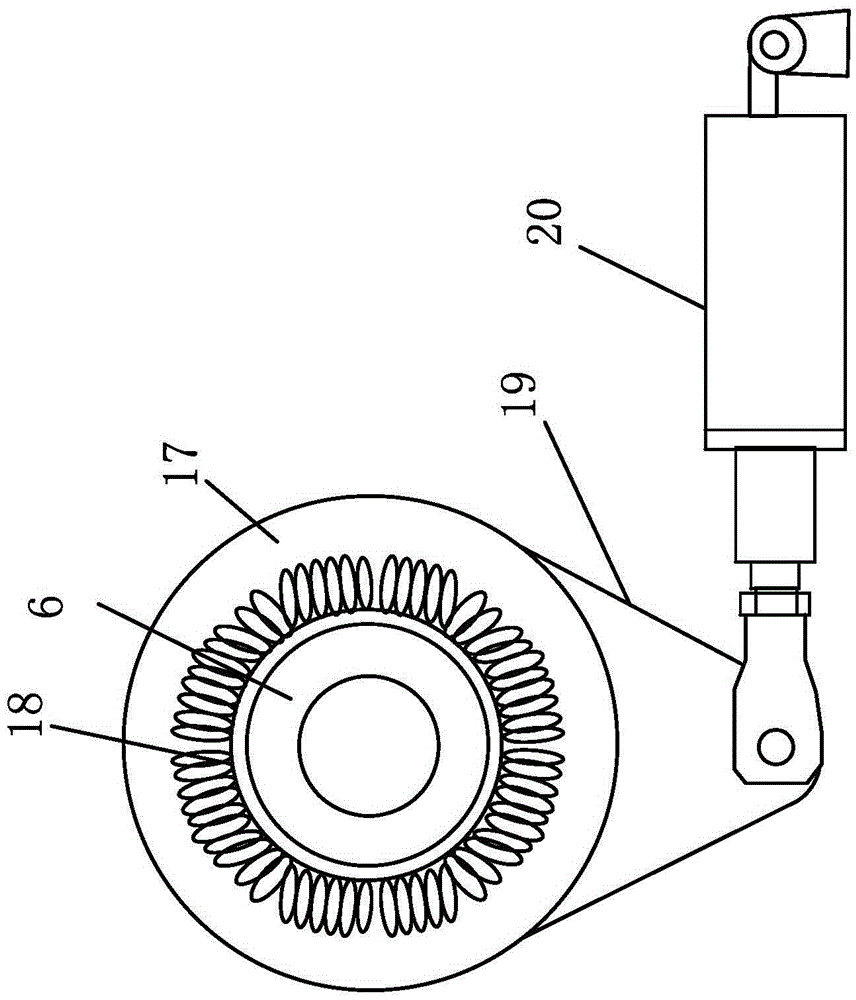

[0039] Such as figure 1 As shown, the technical solution of the present invention is: an extruder for producing special special monofilament for edible grade transportation, comprising barrel 1, motor 2, extruding device, feed port 3 and discharge port 4, in the barrel 1. One end is provided with a material inlet 3, and the other end is provided with a material outlet 4. A material chamber is axially provided in the barrel 1. The extrusion device is placed in the material chamber rotatably. The output of the motor 2 The shaft is connected to the extruder through the housing 5, and the extruder includes a screw 6, and the feeding mechanism, the melting mechanism, the plasticizing mechanism and the extrusion mechanism are arranged on the screw 6 in sequence, and the described feeding mechanism Set close to the housing 5.

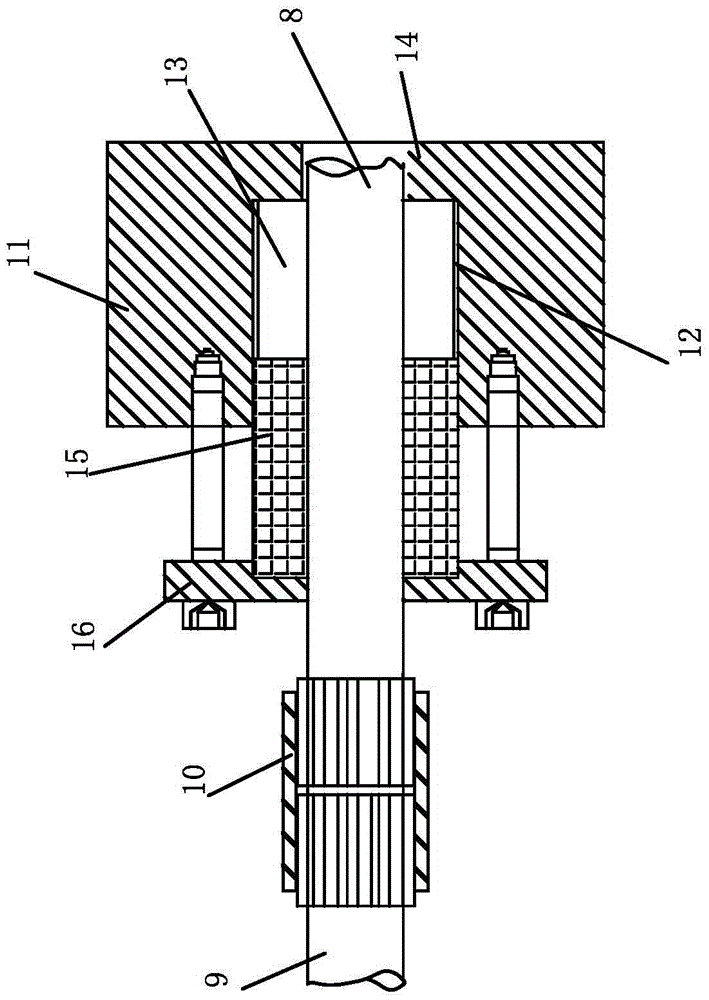

[0040] Such as figure 2 As shown, the screw rod 6 in the feeding mechanism is connected to the supporting part 8 through a coupling, one end of the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com