Table tool

A tool and desktop technology, applied in the direction of manufacturing tools, wood processing equipment, mitering work equipment, etc., can solve the problems of mechanical loss, loss, overheating damage, etc., and achieve the effect of avoiding overload damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

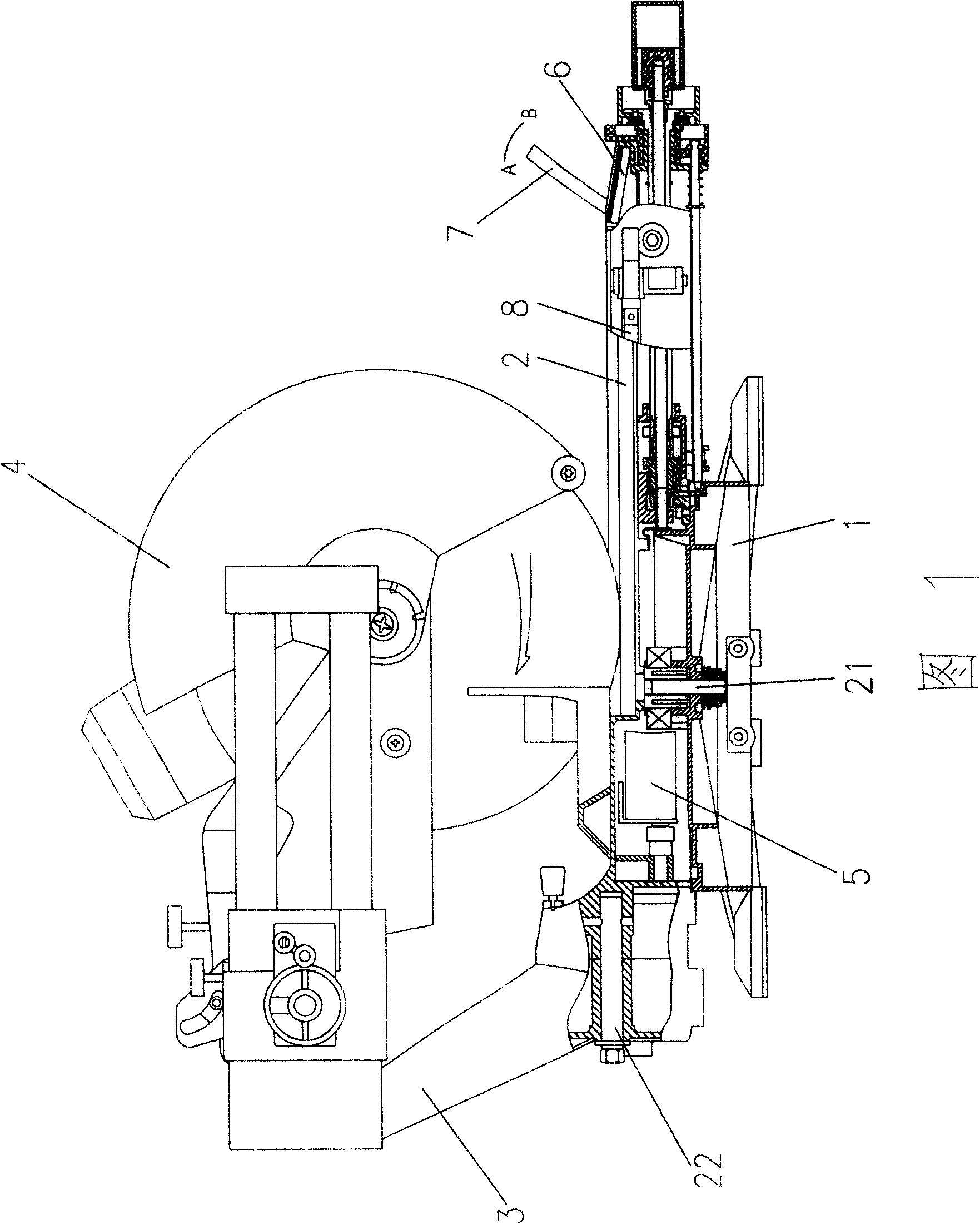

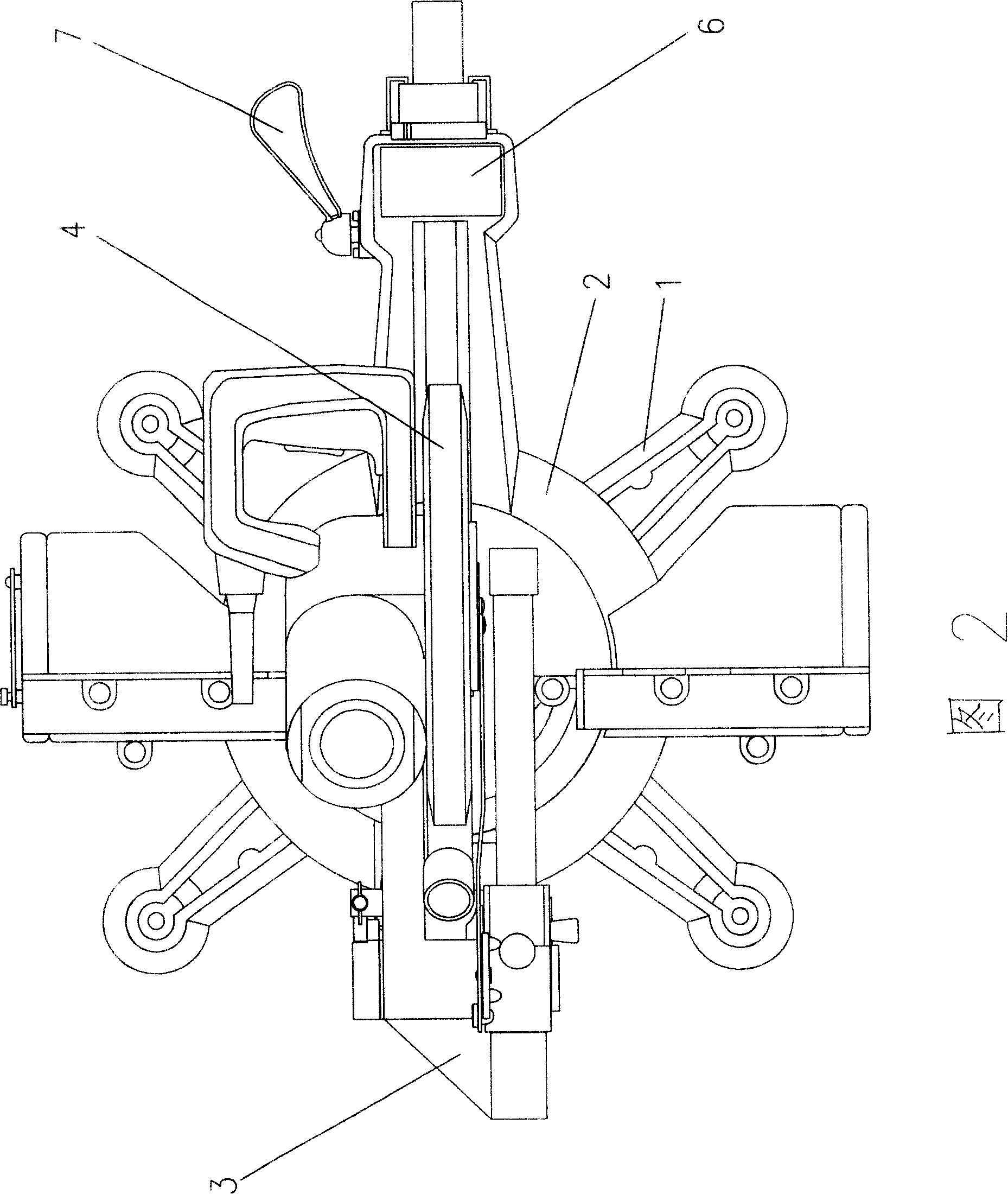

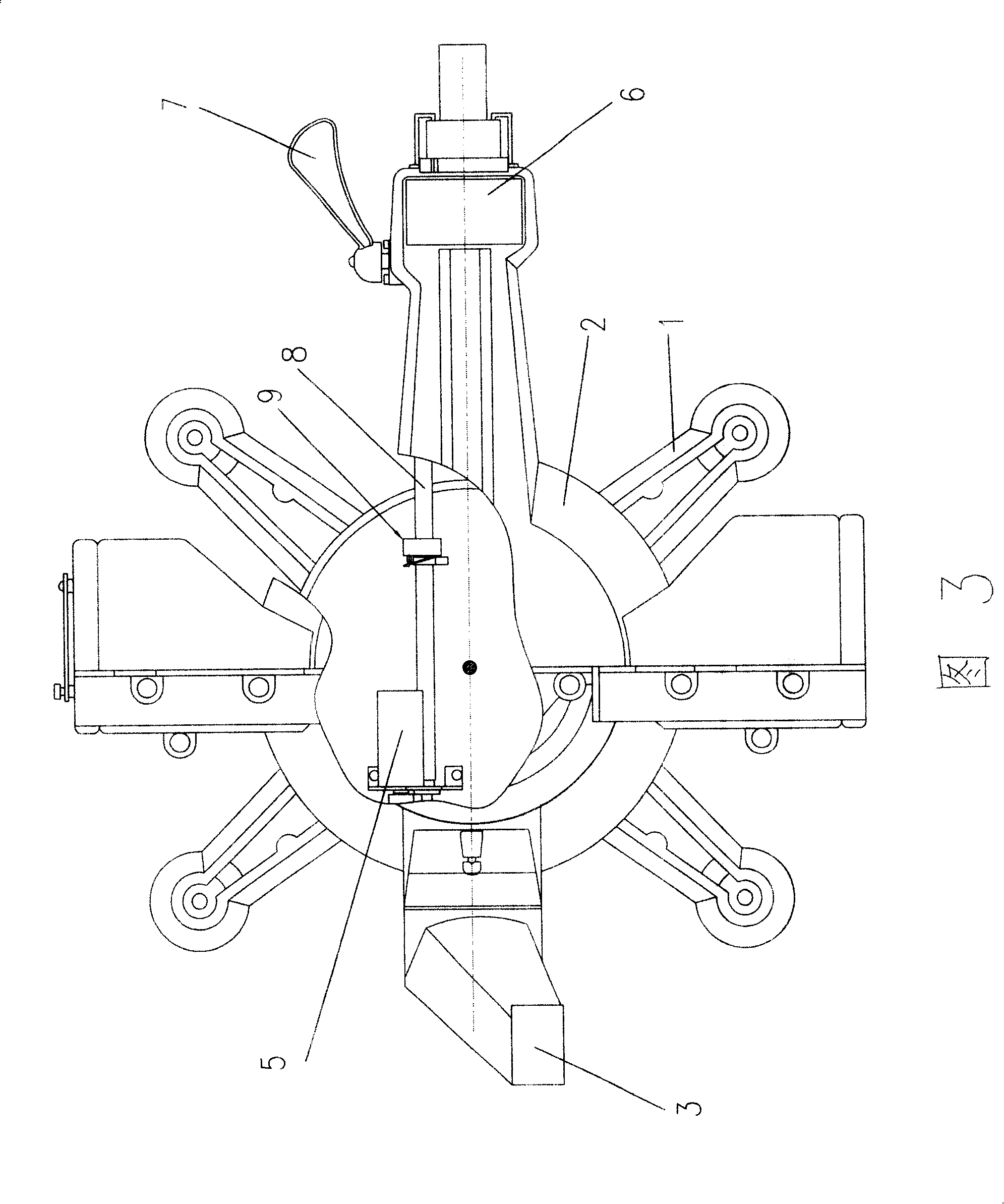

[0034] 1 to 3, the desktop tool disclosed in the present invention is a miter cutting machine, including a base 1, a worktable pivotally connected to the base 1, a machine arm 3 pivotally connected to the worktable 2, and The working head 4 at the free end of the arm 3, where the working head 4 is a saw head, is driven by a main motor to rotate and work. The workbench 2 and the base 1 are pivotally connected together by a first pivot 21, so that the workbench 2 can be rotated in a horizontal direction; the arm 3 and the workbench 2 are pivoted by a second pivot 22 The ground is connected together so that the arm 3 can be rotated in the vertical direction.

[0035] In order to precisely control the rotation angle of the worktable 2 and the arm 3, both of them are controlled by a fine-tuning motor 5. Here, the arm 3 adopts the fine-tuning motor 5 as an example for description. The fine-tuning motor 5 is arranged inside the workbench 2, and is electrically connected to the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com