Train dead-hooking treatment system and method for

A technology for handling systems and trains, applied in the field of engineering, can solve problems such as accelerated damage to the boom and hook head of positioning vehicles, inability to remove them, and affecting unloading efficiency, so as to avoid trains falling off the track and overturning, avoiding huge impacts, and avoiding overload damage. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

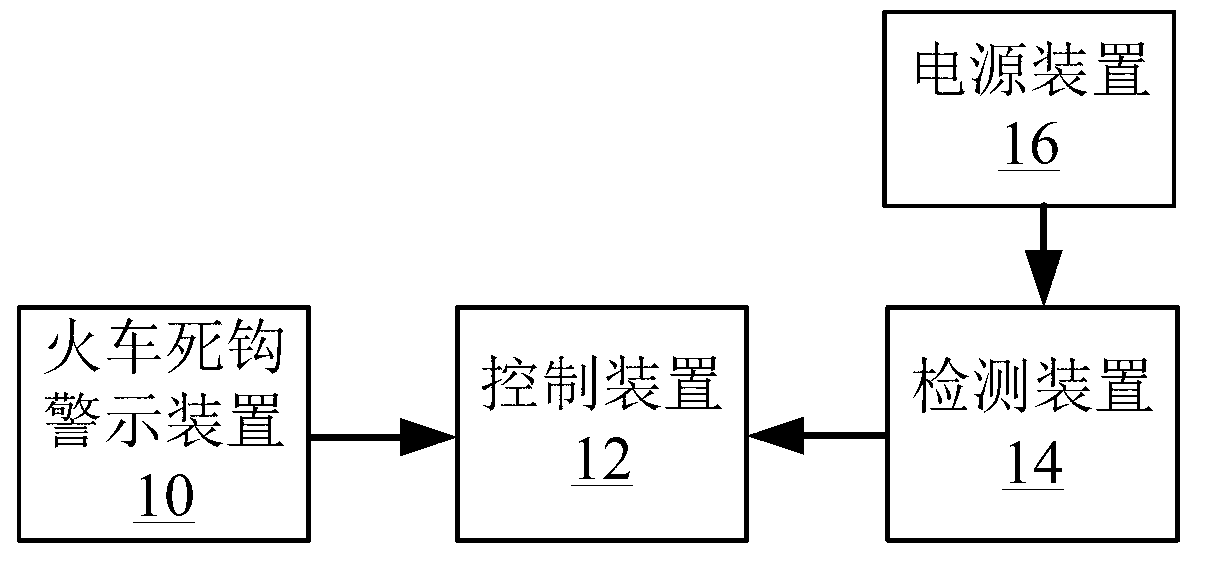

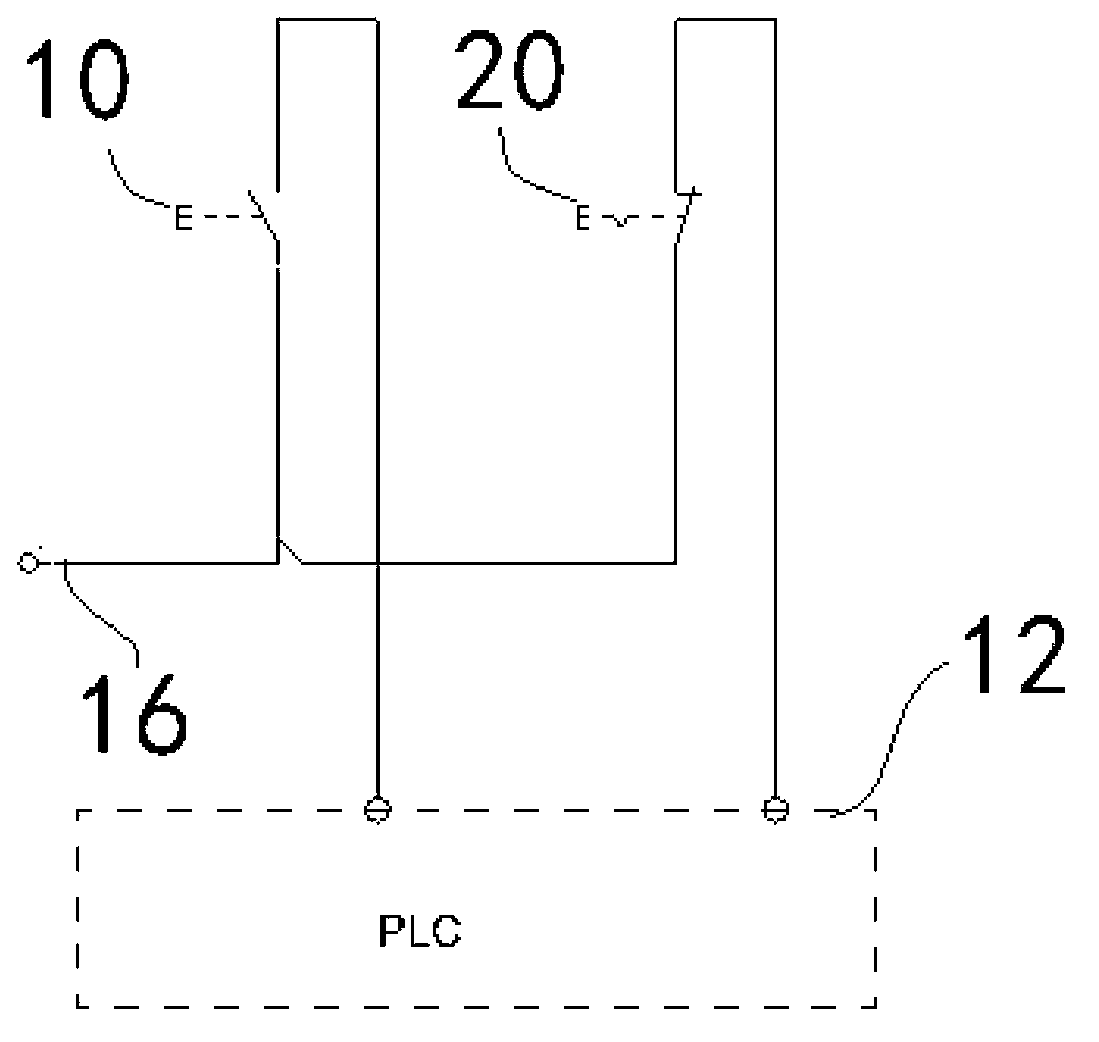

[0018] figure 1 is a block diagram of a train dead hook processing system according to an embodiment of the present invention. Wherein, the train includes multiple heavy train trains.

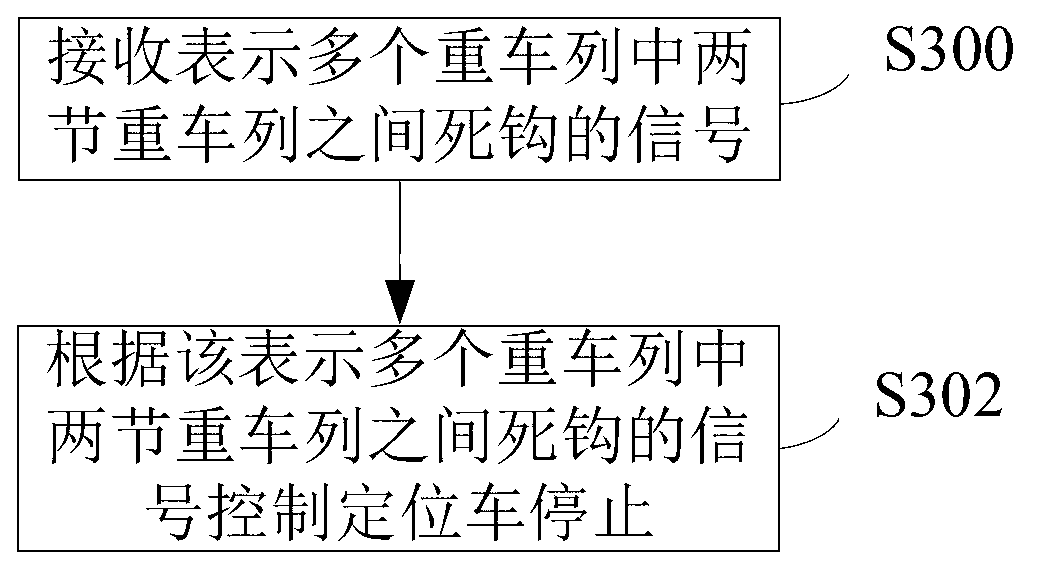

[0019] Such as figure 1 As shown, the system includes: a train dead hook warning device 10, which is used to send a signal representing a dead hook between two heavy train trains in a plurality of heavy train trains; and a control device 12, which is connected with the train dead hook warning device 10, It is used to receive the signal indicating the dead hook between two heavy trains in multiple heavy trains, and control the positioning when receiving the signal indicating the dead coupler between two heavy trains in multiple heavy trains The car stops, wherein the positioning car is used to pull the heavy train and position the heavy train.

[0020] By sending and receiving signals representing dead hooks between two heavy trains in multiple heavy trains and controlling the positioning veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com