White smoke removal equipment for flue gas from exhaust chimney of chemical plant

A technology for exhaust chimneys and chemical plants, which is used in gas treatment, chemical instruments and methods, and dispersed particle filtration. , Improve stability and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

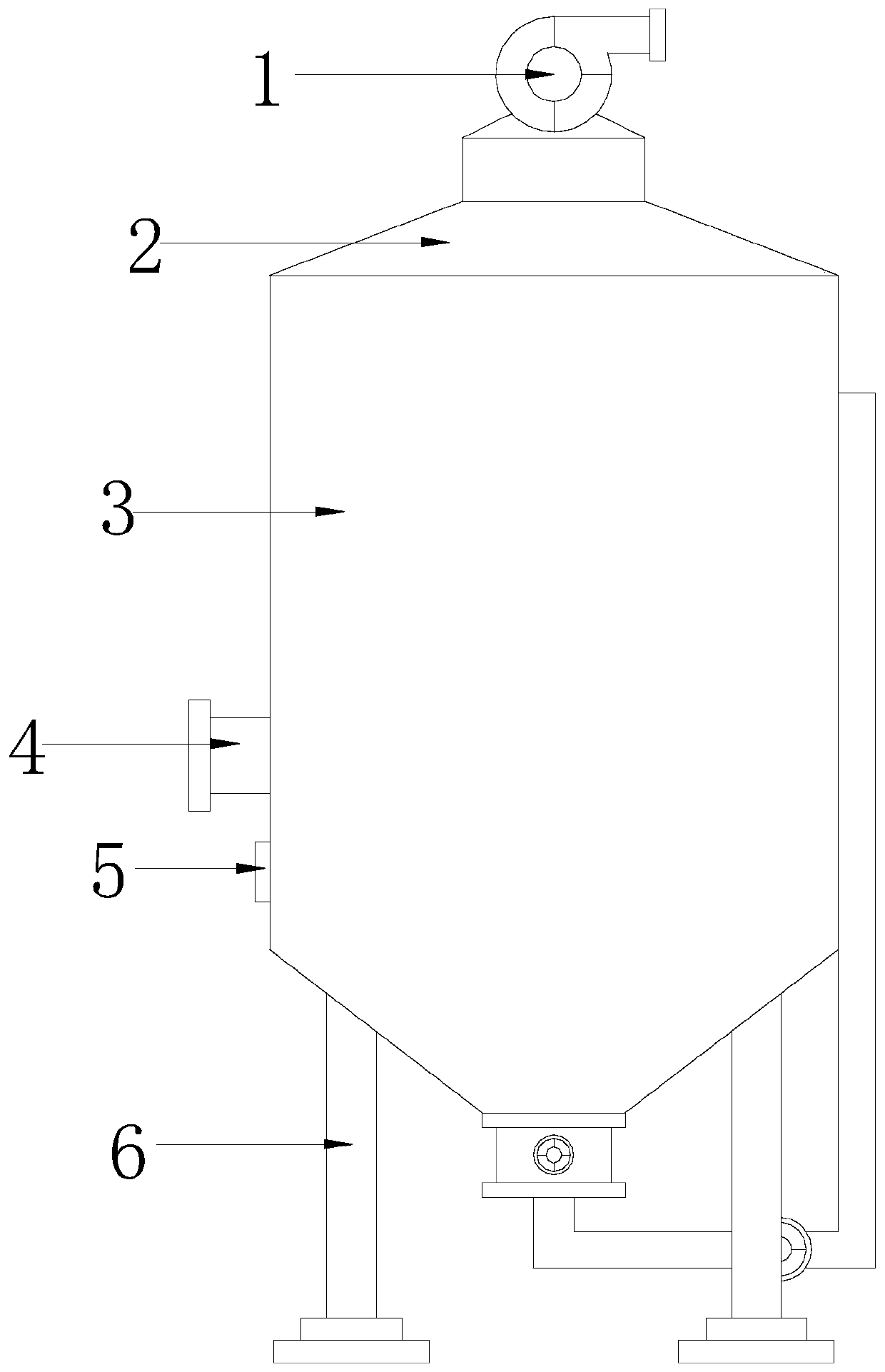

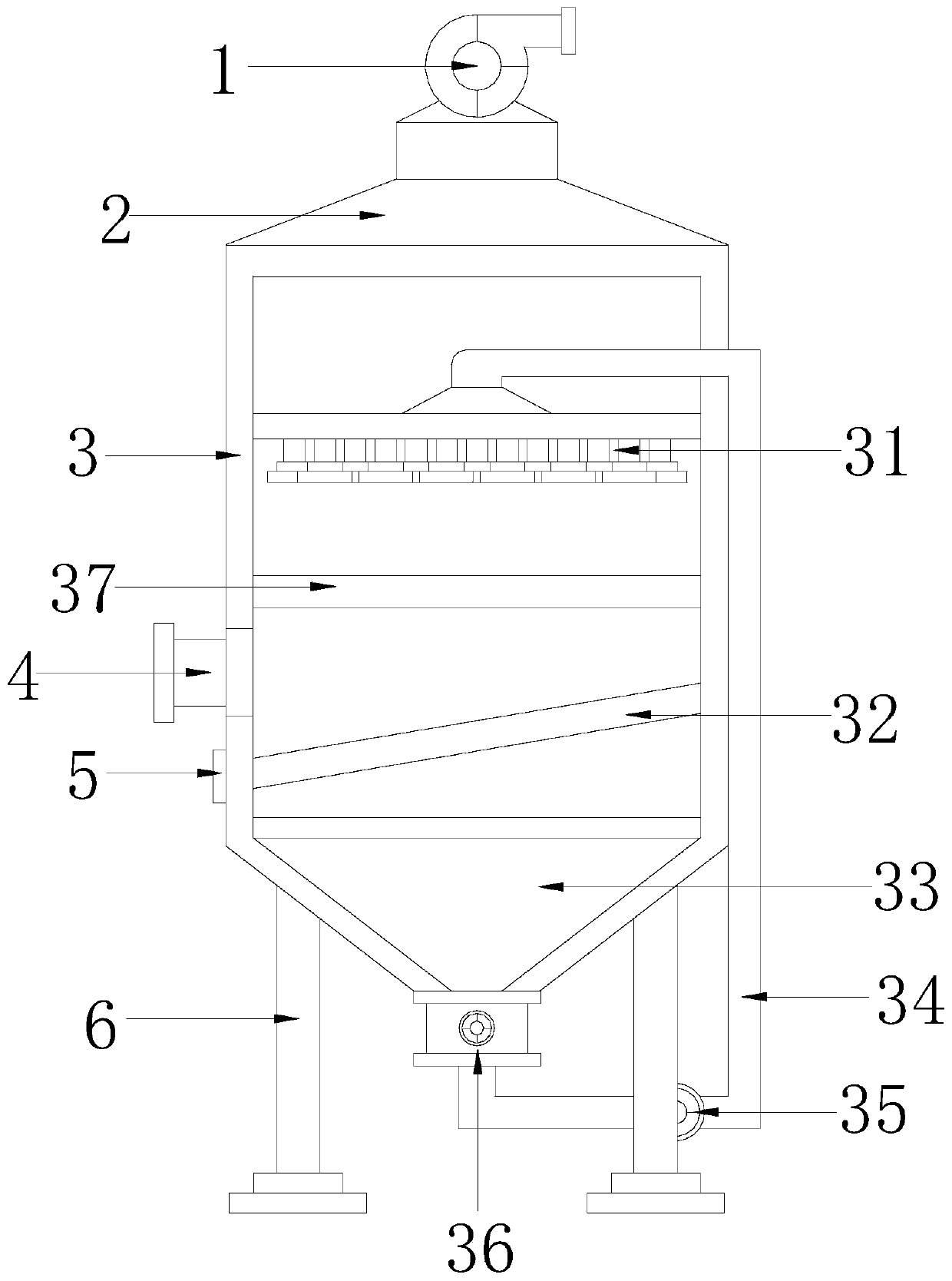

[0032] see Figure 1-4 , the present invention provides a technical scheme of flue gas dewhitening equipment for exhaust chimneys of chemical plants: its structure includes a suction fan 1, a flue gas treatment device 2, a flue gas dewhitening body 3, a smoke inlet 4, and a sewage outlet 5 , support feet 6, a suction fan 1 is installed on the top of the flue gas de-whitening body 3, and a flue gas treatment device 2 connected to the flue gas de-whitening body 3 is arranged below the suction fan 1, and the flue gas de-whitening The bottom of the body 3 is vertically connected with a supporting foot 6, and a smoke inlet 4 is installed on one side of the flue gas dewhitening body 3, and a sewage outlet 5 connected with the flue gas dewhitening body 3 is provided under the smoke inlet 4 ;

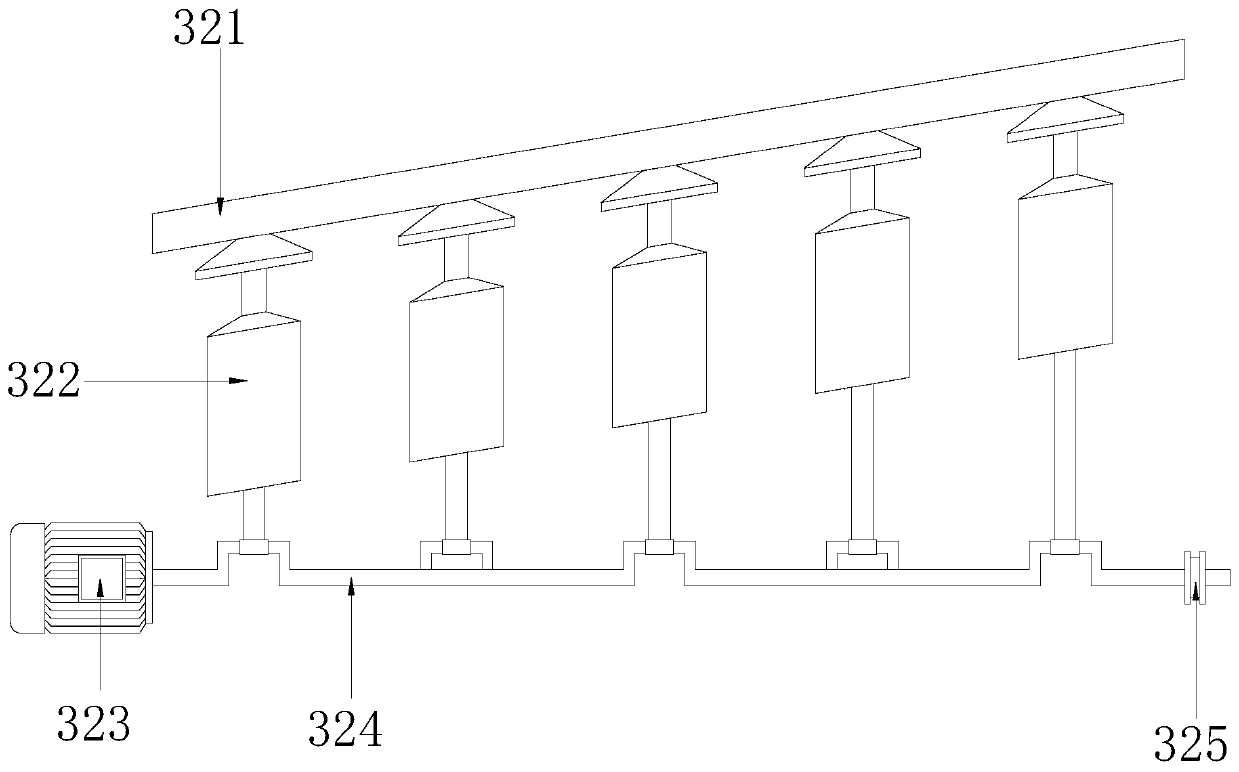

[0033] The flue gas dewhitening machine body 3 also includes a water uniform sprayer 31, a filter device 32, a water circulation bucket 33, a water circulation pipe 34, a water pump 35, and a ...

Embodiment 2

[0038] see Figure 1-8 , the present invention provides a technical scheme of flue gas dewhitening equipment for exhaust chimneys of chemical plants: its structure includes a suction fan 1, a flue gas treatment device 2, a flue gas dewhitening body 3, a smoke inlet 4, and a sewage outlet 5 , support feet 6, a suction fan 1 is installed on the top of the flue gas de-whitening body 3, and a flue gas treatment device 2 connected to the flue gas de-whitening body 3 is arranged below the suction fan 1, and the flue gas de-whitening The bottom of the body 3 is vertically connected with a supporting foot 6, and a smoke inlet 4 is installed on one side of the flue gas dewhitening body 3, and a sewage outlet 5 connected with the flue gas dewhitening body 3 is provided under the smoke inlet 4 ;

[0039] The flue gas dewhitening machine body 3 also includes a water uniform sprayer 31, a filter device 32, a water circulation bucket 33, a water circulation pipe 34, a water pump 35, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com