Cable hoisting machine pre-stress rear anchor

A technology of cable cranes and prestressed anchor cables, which is applied in the direction of cable cranes, cranes, erection/assembly of bridges, etc., and can solve problems such as large engineering volume and occupied area, increased weight and frictional resistance, and large volume of rear anchors , to achieve the effect of small excavation works, flexible use, saving cost and construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

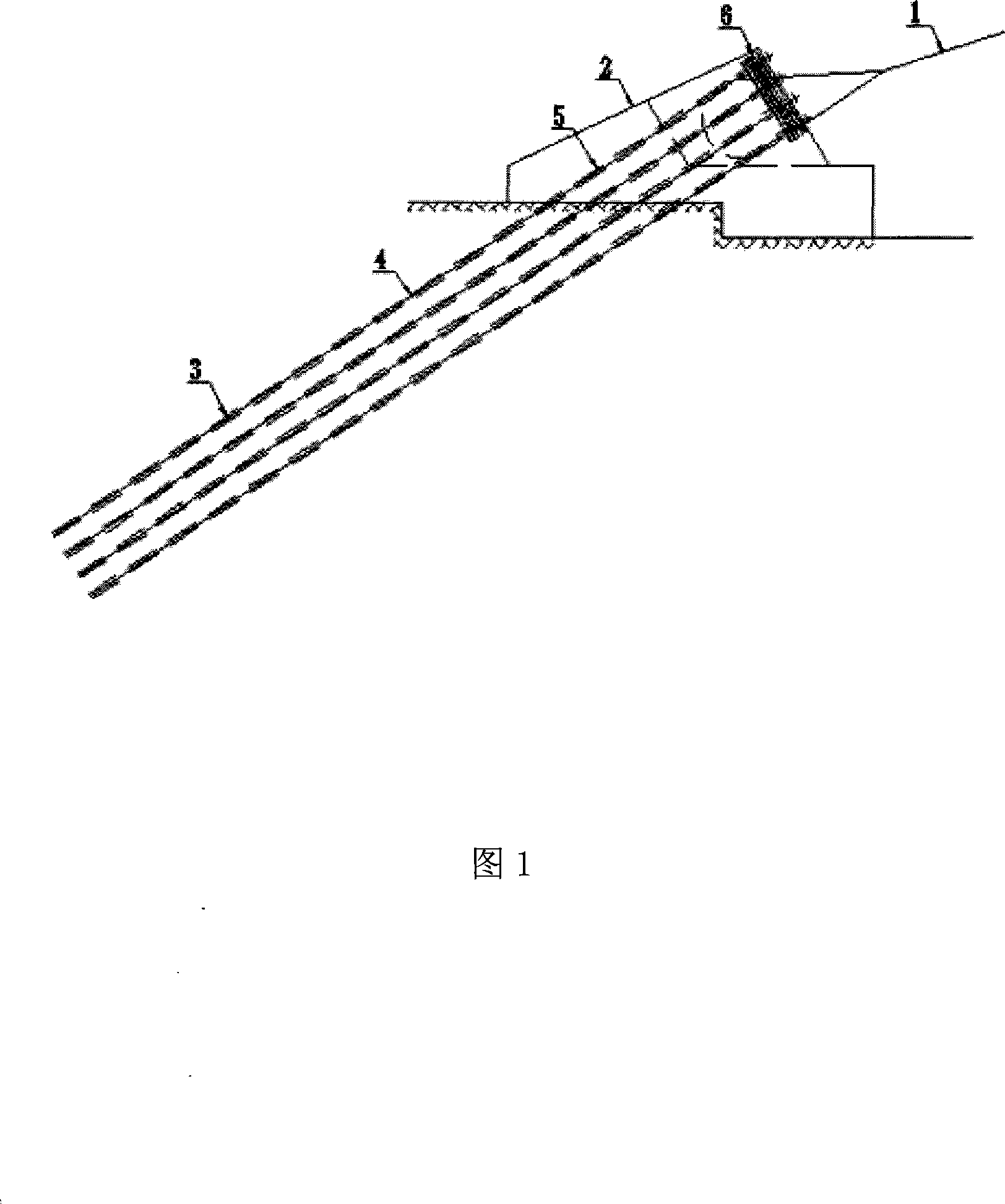

[0020] With reference to the accompanying drawings, the wooden prestressed anchor is composed of three parts: the anchor hole, the prestressed anchor cable, and the concrete rear anchor. 6 is connected with corrugated pipe 5, cable 1 and concrete rear anchor 2.

[0021] The diameter of the anchor hole 3 is 70-110mm, the spacing is 1-1.5m, the horizontal inclination is 30°-60°, and the depth is 10-20m. Drilling generally uses a small pneumatic drilling rig, which is flexible and convenient to disassemble and move, and is suitable for various terrains and rock formations.

[0022] The prestressed anchor cables are bundled with steel strands, 4 to 8 as a bundle. The anchor cables 4 are anchored in the anchor holes 3. Anchor 2 front end. 4 to 8 strands are put into the anchor hole after being braided, and then grouted into the hole. After the cement slurry reaches the design strength, the anchor cable is anchored in the rock body through the bonding force. The anchoring length i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Horizontal inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com