Method and device for validating special object on weighing conveyer

A technology for specific objects and conveyors, applied in the direction of conveyor objects, using optical devices, measuring devices, etc., can solve problems such as data disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

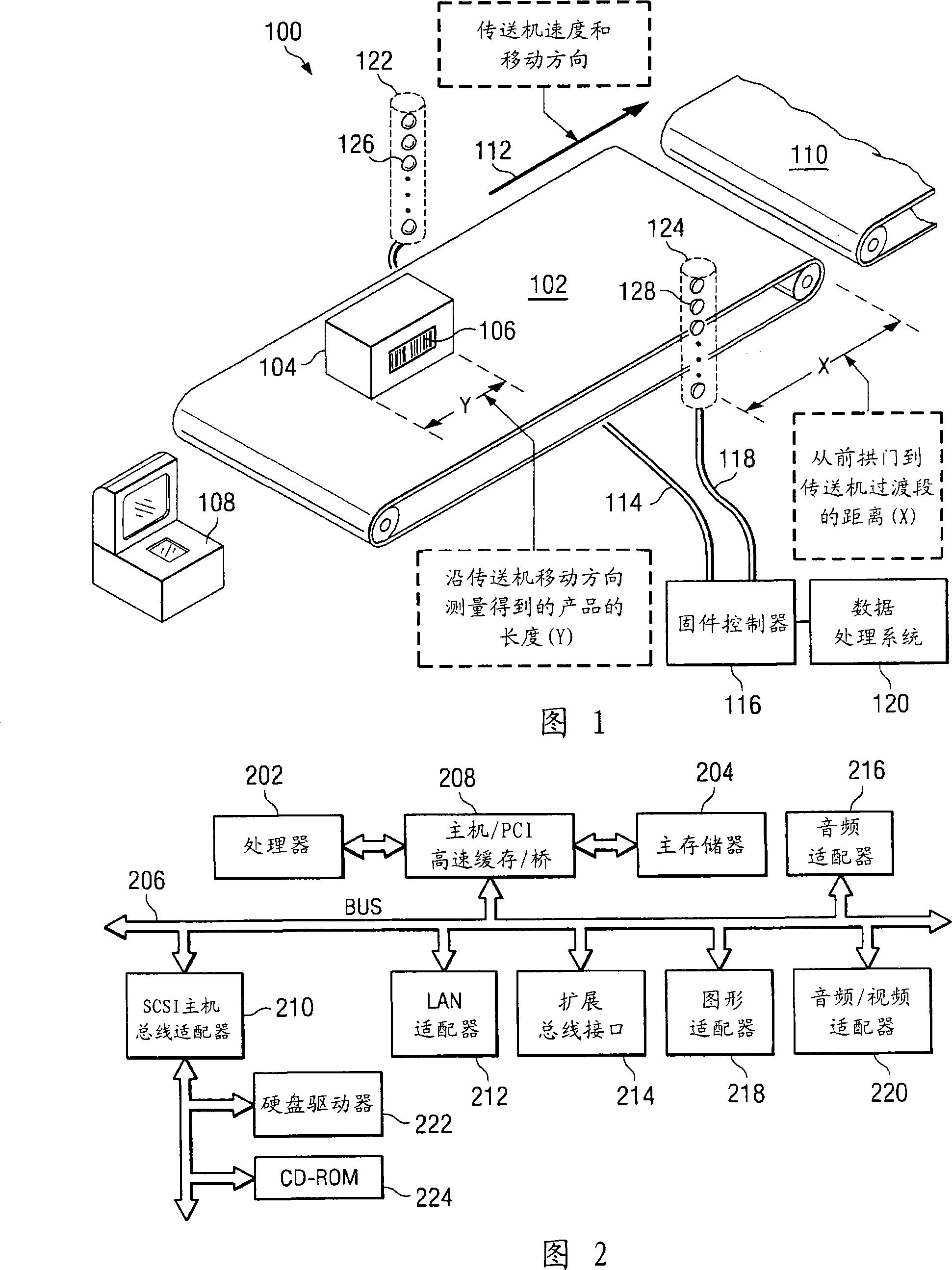

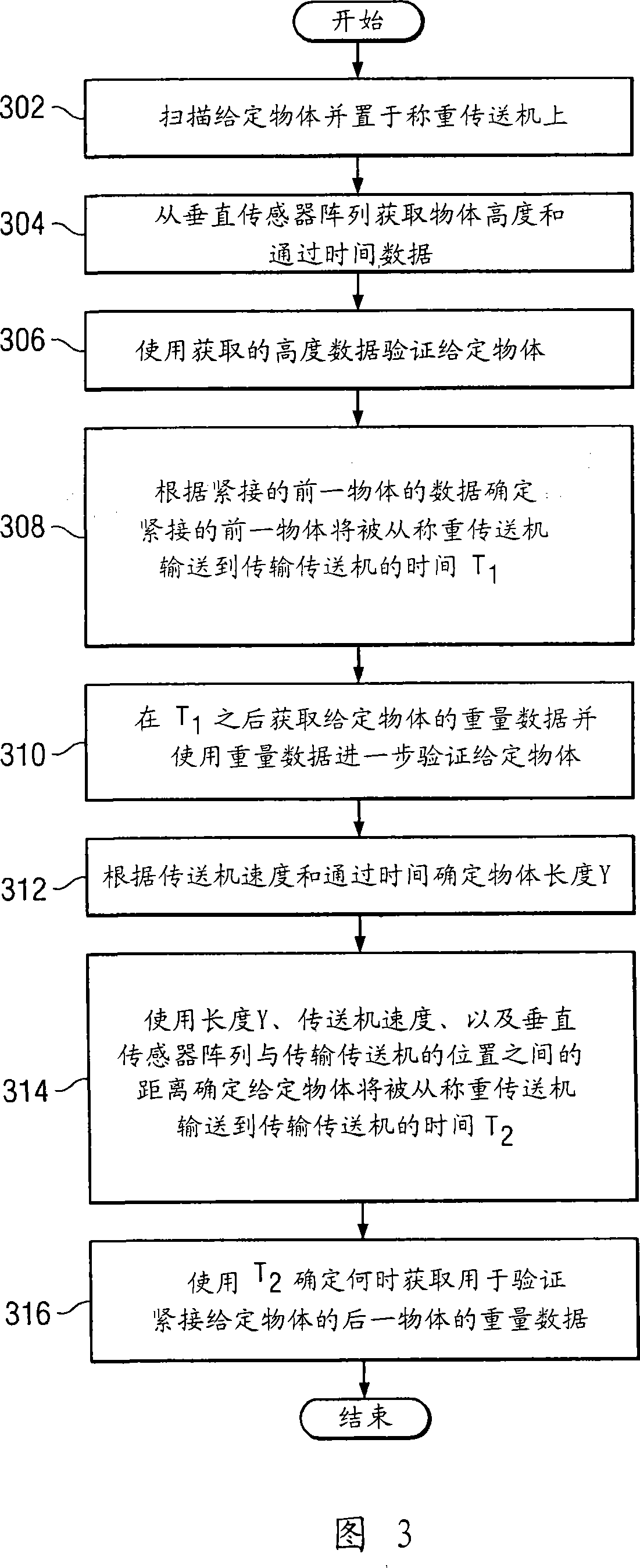

[0013] Referring to FIG. 1 , there is shown components configured to make up a self-checkout system 100 of an embodiment of the present invention. The system 100 is equipped with a scale-mounted weighing conveyor 102 for receiving, weighing and moving objects 104, which may be products, items, and the like. The system 100 may be used in stores selling various goods, but the present invention is not limited thereto. In general, the system 100 can be utilized wherever automatic verification or validation of an object as belonging to a particular object type, class or category is desired.

[0014] Typically, a scannable identifier, such as a barcode label 106 , is affixed to each object 104 to be read by a barcode scanner 108 . In one embodiment, the scanner 108 is fixed at a location in front of the conveyor to automatically scan the labels of the individual objects as they move through the scanner before being placed on the conveyor 102 . In another implementation, scanner 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com