Li-ion pole coiling method and coiling pin for the method

A technology of lithium batteries and rolling needles, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries, etc. It can solve the problems of no improvement, the maximum pressure of positive and negative electrodes, etc.

Inactive Publication Date: 2008-07-02

BYD CO LTD

View PDF2 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This kind of winding needle improves the curvature of the first bending part of the wound-out pole core, but the condition that the separator at the first bending part bears the maximum pressure of the positive electrode sheet and the negative electrode sheet has not been improved.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0069] Using the first implementation of the winding needle of this aspect, use the method described in the first embodiment of the winding method of this aspect to wind.

example 2

[0071] Using the second embodiment of the winding needle of this aspect, use the method described in the second embodiment of the winding method of this aspect to wind.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

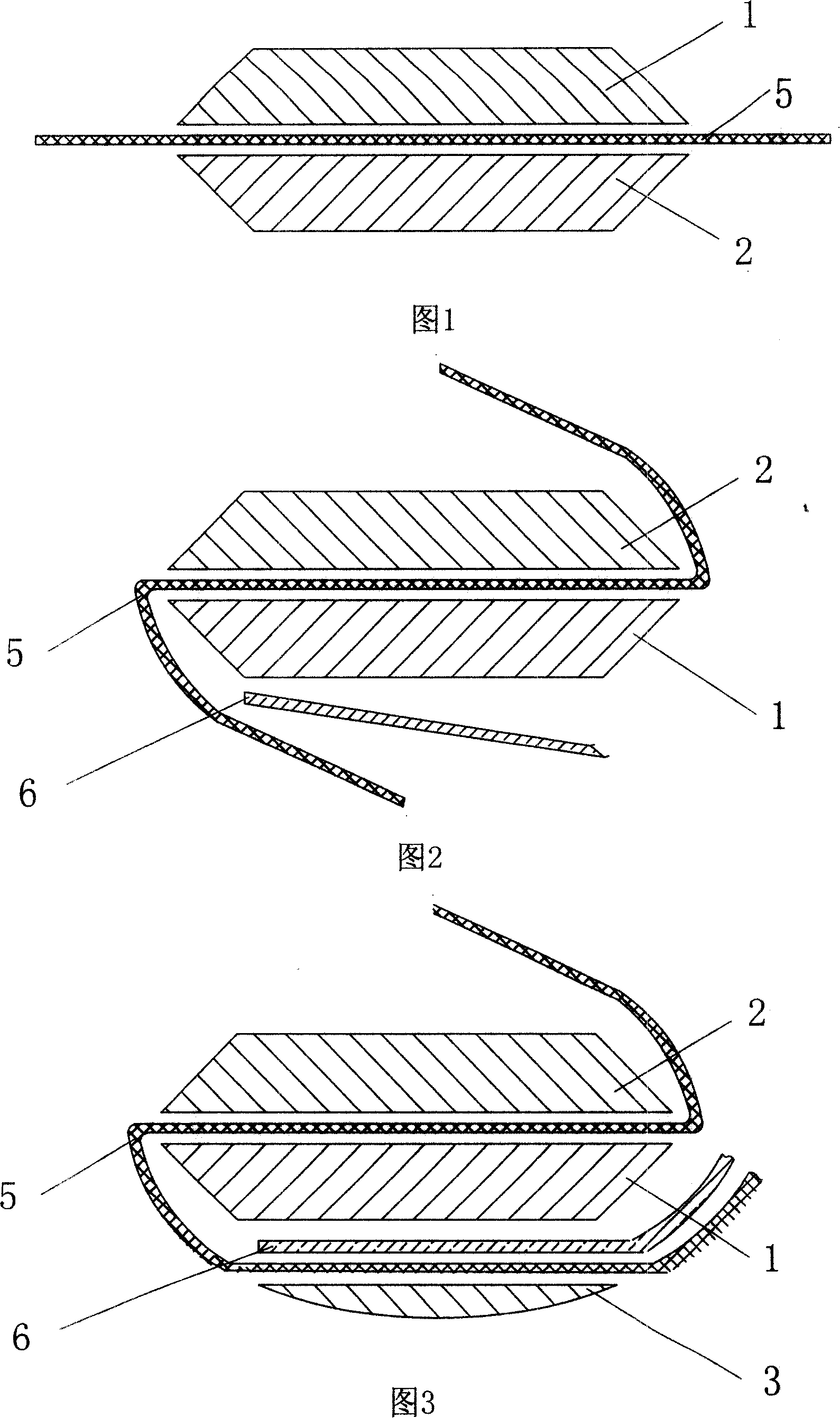

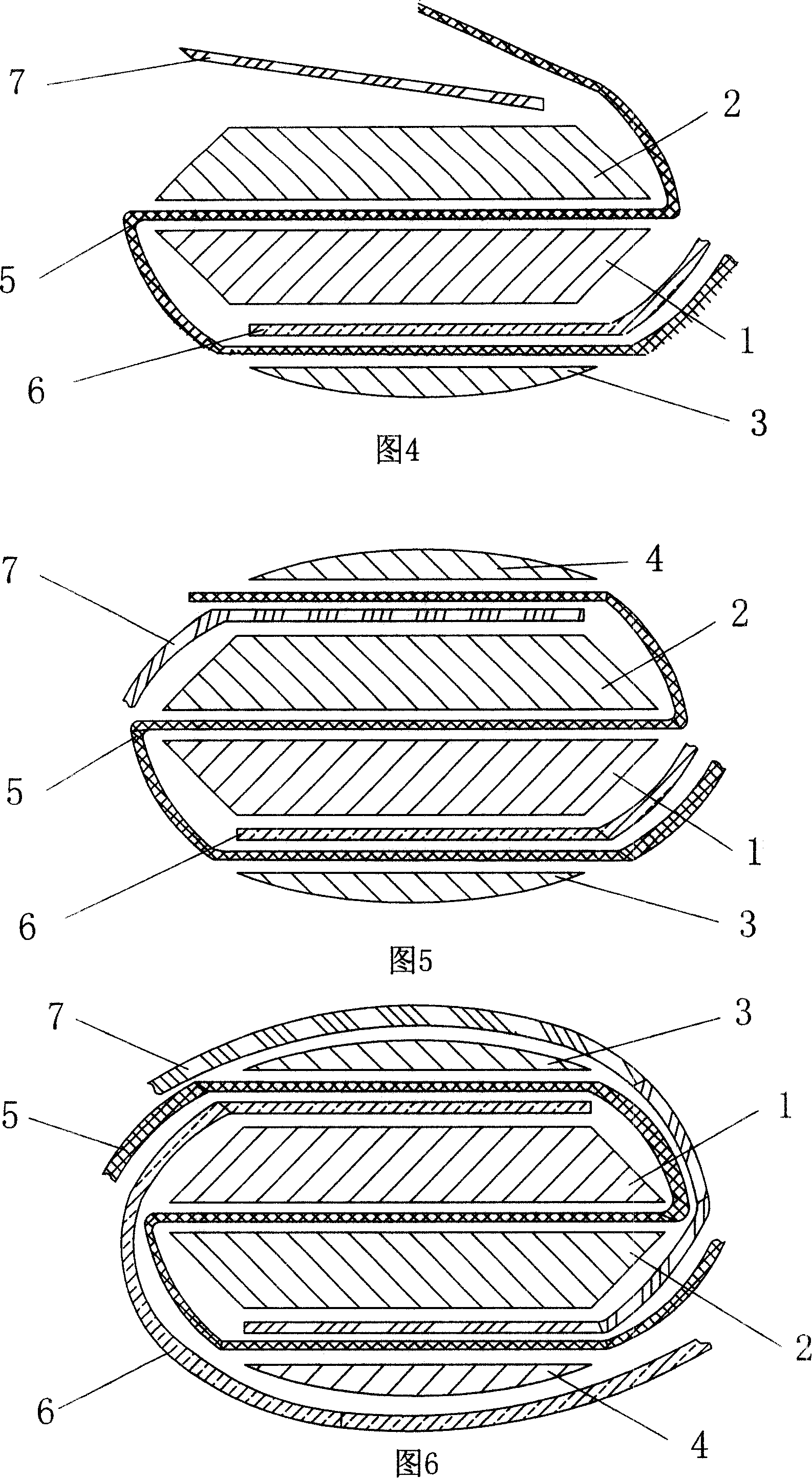

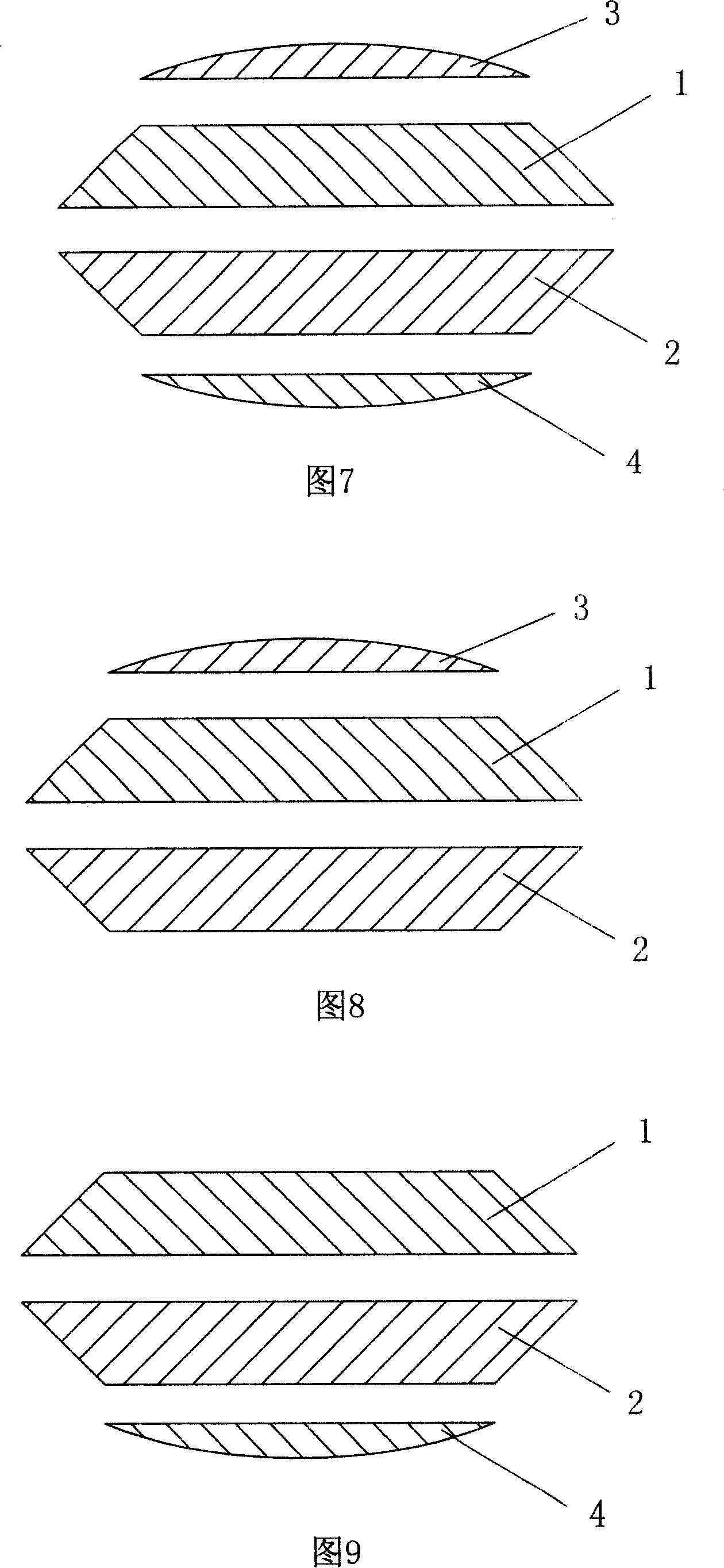

The invention relates to an involution method for a lithium battery and a rolling needle used in the method. The method comprises the processes: a cathode slice is inserted between a diaphragm and a first rolling needle; a second rolling needle is fixedly arranged on a basement and holds the diaphragm and the top end of the cathode slice with the first rolling needle; the anode slice is inserted between the diaphragm and the first lower rolling needle. The given circle number is arrived after involution; the polar core is token after completing the involution. The rolling needle comprises a first upper rolling needle, a first lower rolling needle and a second upper rolling needle. The length of the bottom of the second upper rolling needle is equal to that of the top edge of the first upper rolling needle. The section of the second upper rolling needle presents a shape that the thickness of the two edge parts is less than the thickness of the middle part. The outer side frame can form a smooth transition with the side edges of the trapezoid. The second upper rolling needle and the first upper rolling needle can hold the diaphragm of the polar core and the rolling ends of the cathode slice. By adopting the method disclosed in the invention, the middle of the polar core rolled by the rolling needle is loose, which relieves the force from the anode slice and cathode slice borne by the diaphragm in the first bending place.

Description

technical field [0001] The invention relates to a winding method of a lithium battery pole core, in particular to a method of increasing the relative distance between the diaphragm and the pole piece at the first bending position of the pole core, and relieving the diaphragm from bearing the pressure of the positive and negative pole pieces. Winding method of lithium battery pole core. [0002] The present invention also relates to a winding needle used for winding lithium battery pole cores, in particular to a method that increases the relative distance between the diaphragm and the pole piece at the first bending position of the lithium battery pole core, thereby relieving the diaphragm from being subjected to negative pressure. Negative plate pressure of the roll pin. Background technique [0003] Since the commercialization of lithium-ion batteries in the 1990s, lithium-ion batteries have become one of the main power sources for portable electronic products such as mobi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M10/40H01M10/38H01M6/14H01M10/058

CPCY02E60/122Y02E60/10Y02P70/50

Inventor 周耀华金菁黄志娟

Owner BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com