Moving-coil type large range mobile magnetic floating six-freedom worktable

A large-scale, high-degree-of-freedom technology, applied in the direction of manufacturing tools, large fixed members, metal processing equipment, etc., can solve the problem that the moving range is relatively small, and achieve the effect of increasing the relative stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

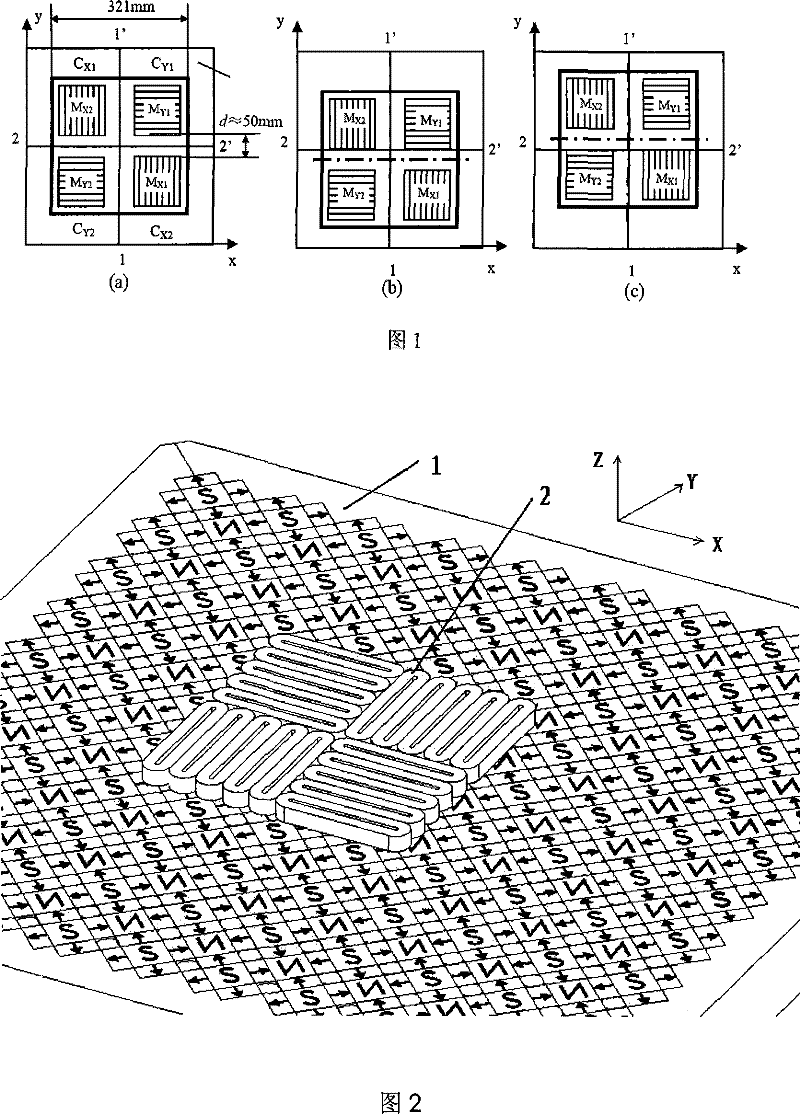

[0019] The specific structure, mechanism and working process of the present invention will be further described below in conjunction with the accompanying drawings.

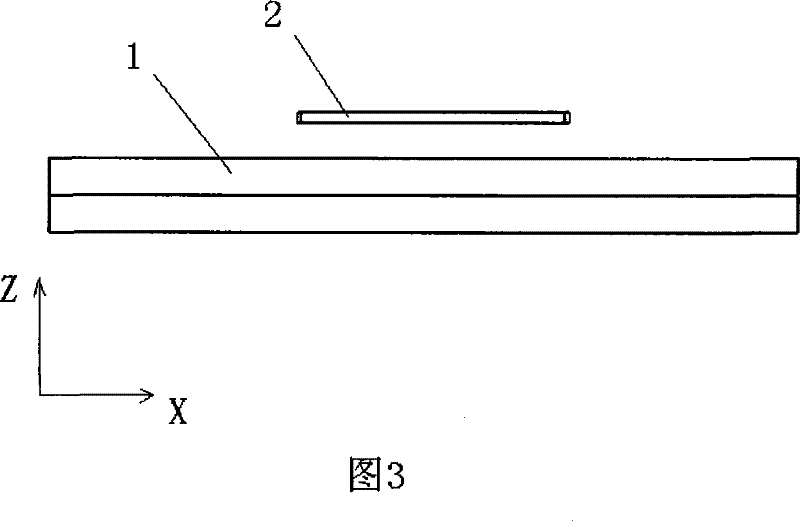

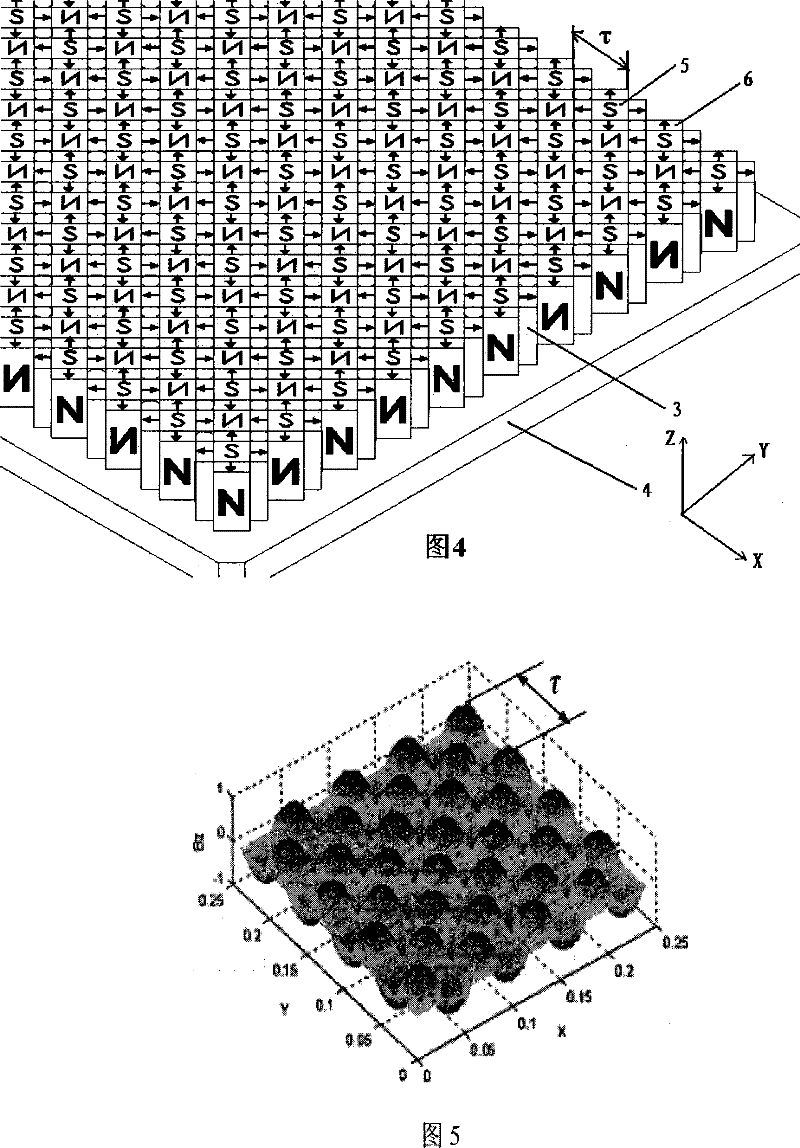

[0020] The moving coil type large-scale mobile maglev six-degree-of-freedom workbench provided by the present invention includes a base 1 and a mobile base 2, and a planar permanent magnet array 3 is arranged on the top of the base. The planar permanent magnet array consists of a series of permanent magnets on the base arranged in a Halbach array; the mobile station 2 is made up of a platform 7 and a mobile electromagnetic structure 8 arranged at the bottom of the platform, and the mobile electromagnetic structure is composed of at least four coil arrays, and each coil array is composed of one or more A rectangular ironless coil is arranged linearly.

[0021] figure 2 It is a three-dimensional view of a specific embodiment of the maglev six-degree-of-freedom workbench of the present invention. It can be seen fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com