Multipolar bit fixture clamp

A tooling fixture and multi-pole technology, applied in the field of tooling fixtures, can solve problems such as low production efficiency, strong limitations of tooling fixtures, and poor safety, and achieve the effects of improving efficiency, breaking through single limitations, and being flexible and light in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

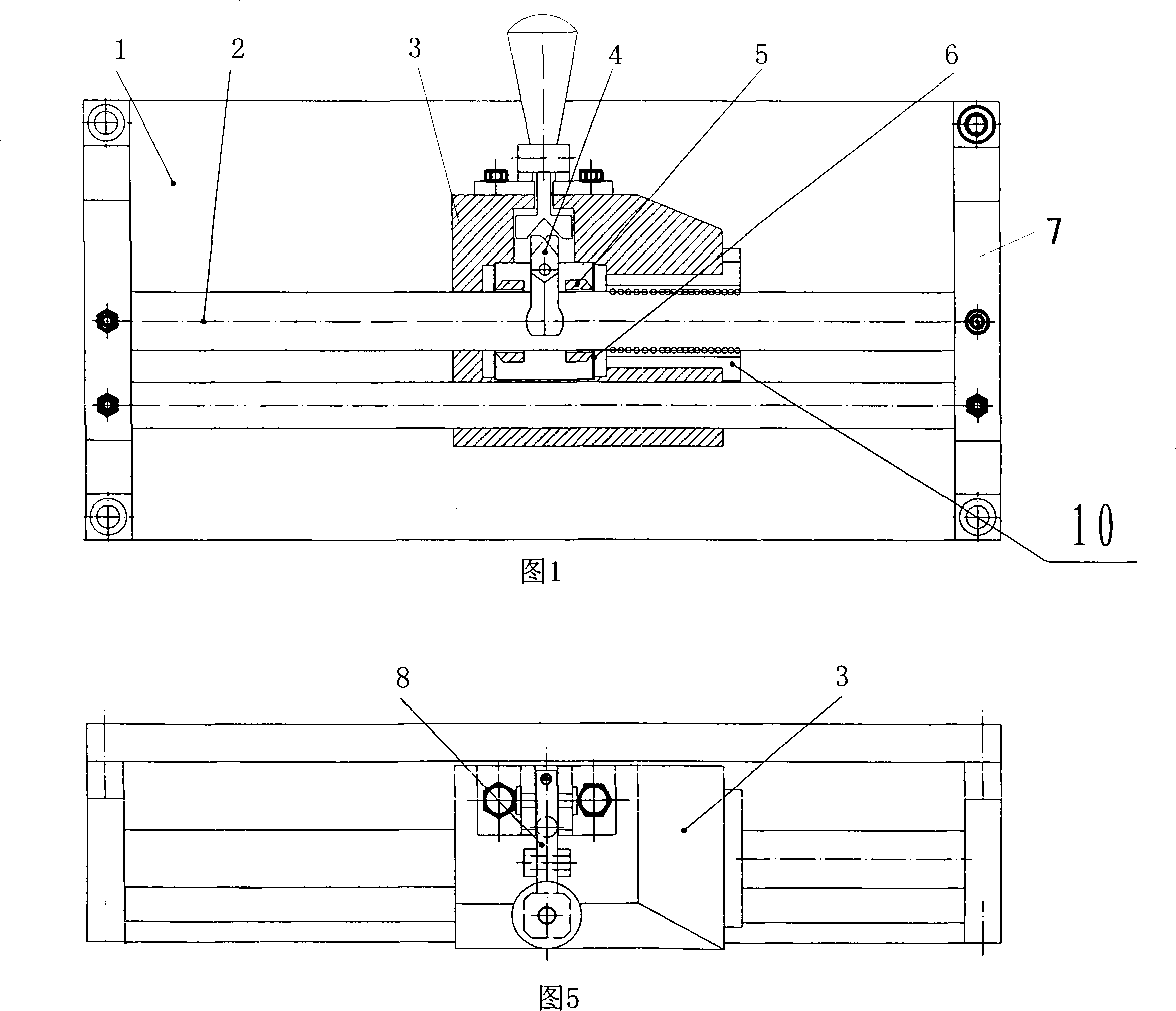

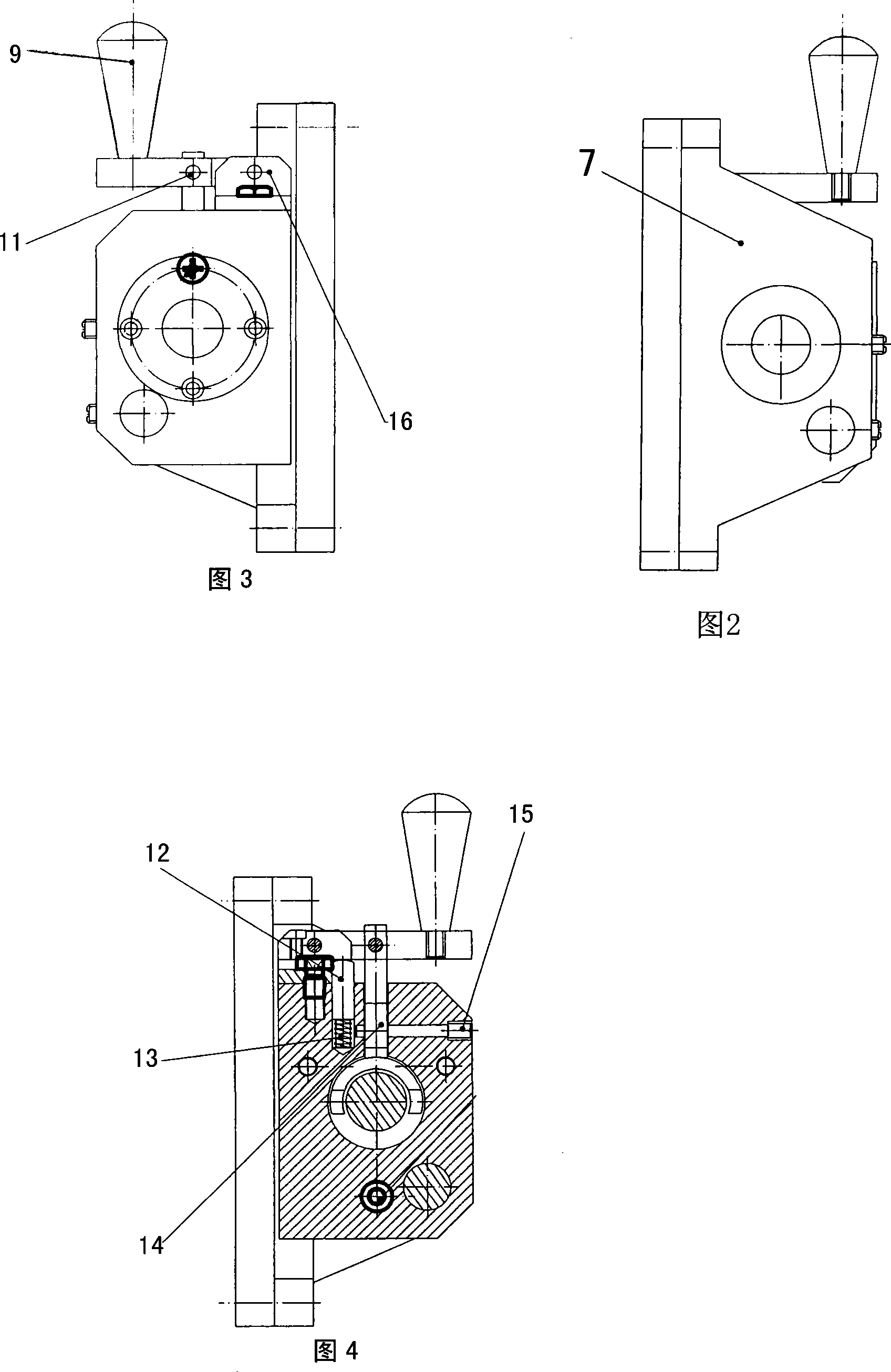

[0027] The base 1 is provided with a bracket 7, the two ends of the straight bar 2 are mounted on the bracket 7, the straight bar 2 is slidably provided with a guide body 3 through a linear bearing 10, and a V-shaped iron 14 is connected to the guide body 3 through a pin shaft 15. The upper end of the shaped iron 14 is fixedly connected with the pulling iron 8 through the pin shaft 11, one end of the pulling iron 8 is connected with the pulling handle 9, the other end of the pulling iron 8 is inserted into the socket 16, and the bottom end of the V-shaped iron 14 is provided with There is an opening and closing plug 4 , and steel sheets 6 are respectively provided on both sides of the opening and closing plug 4 through the plugging sleeve 5 . The guide body 3 is provided with a push rod 12 , the upper extending end of the push rod 12 is in active contact with the pulling iron 8 , and the lower end of the push rod 12 is connected with a spring 13 arranged inside the guide body 3...

Embodiment 2

[0029] The guide body 3 is provided with a cylinder or a hydraulic oil cylinder for automatic control, and other structures are the same as those in Embodiment 1.

[0030] The working process of the present invention is as follows:

[0031] When working, pull the handle 9 to start the pull-down, transmit power to the pulling iron 8, and the pulling iron 8 drives the V-shaped iron 14, forcing the puller 4 to separate, and the puller 4 pushes the two-way synchronous steel sheet 6 on both sides through the pusher sleeve 5 to slide. . When it is not fixed, the spring 13 bounces up the top rod 12, so that the pulling iron 8 pushes the pulling handle 9 to lift away.

[0032] When the workpiece is not in motion, that is, in a fixed position, the tooling can be equipped with a cylinder and a hydraulic cylinder, and the actuator can be operated automatically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com