Embedded forming method and mold for embedded forming

A technology of insert molding and mold, applied in the direction of coating, etc., can solve problems such as deformation of integrated products, deformation of secondary injection molded products, and rupture of secondary injection molded products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

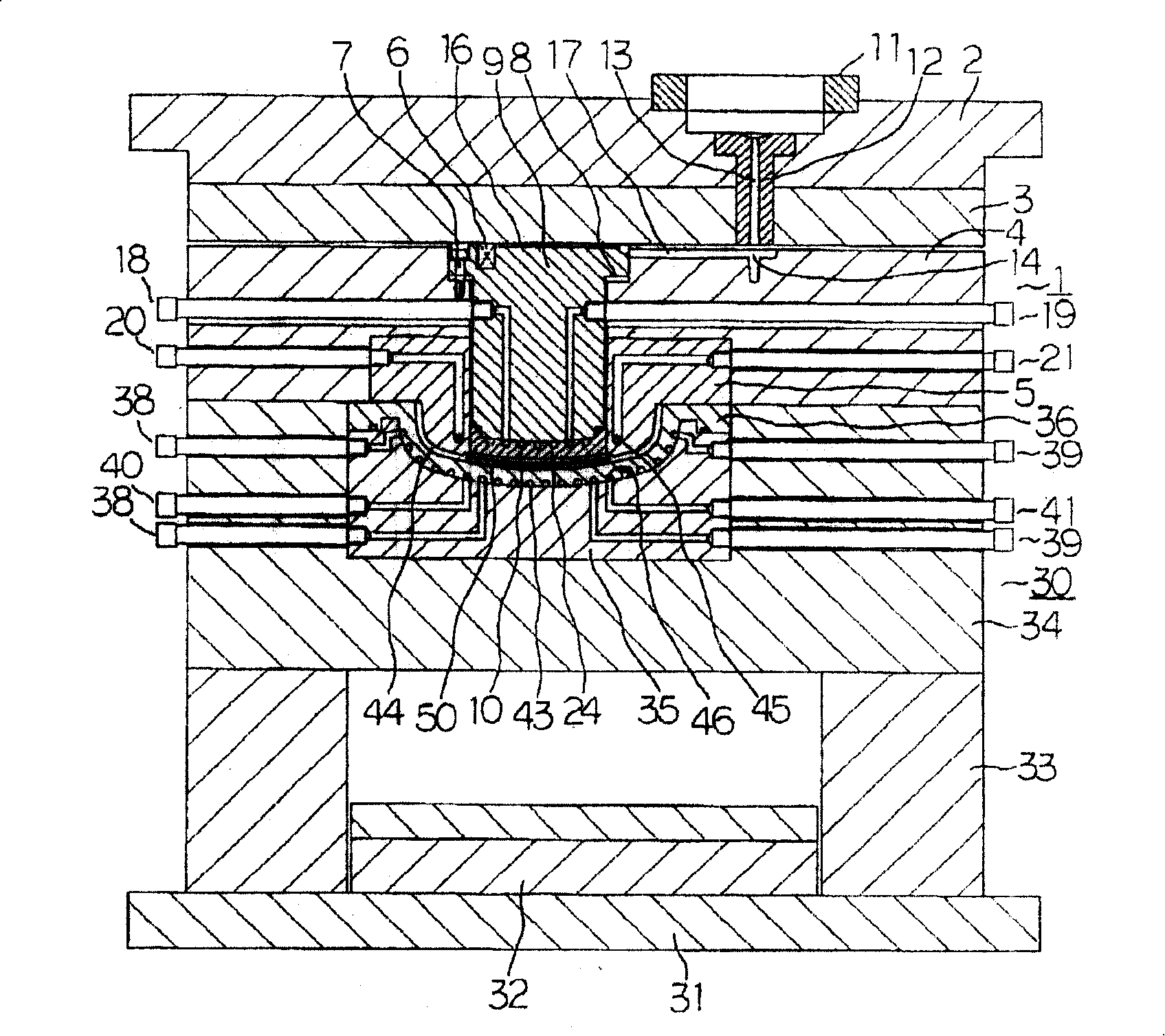

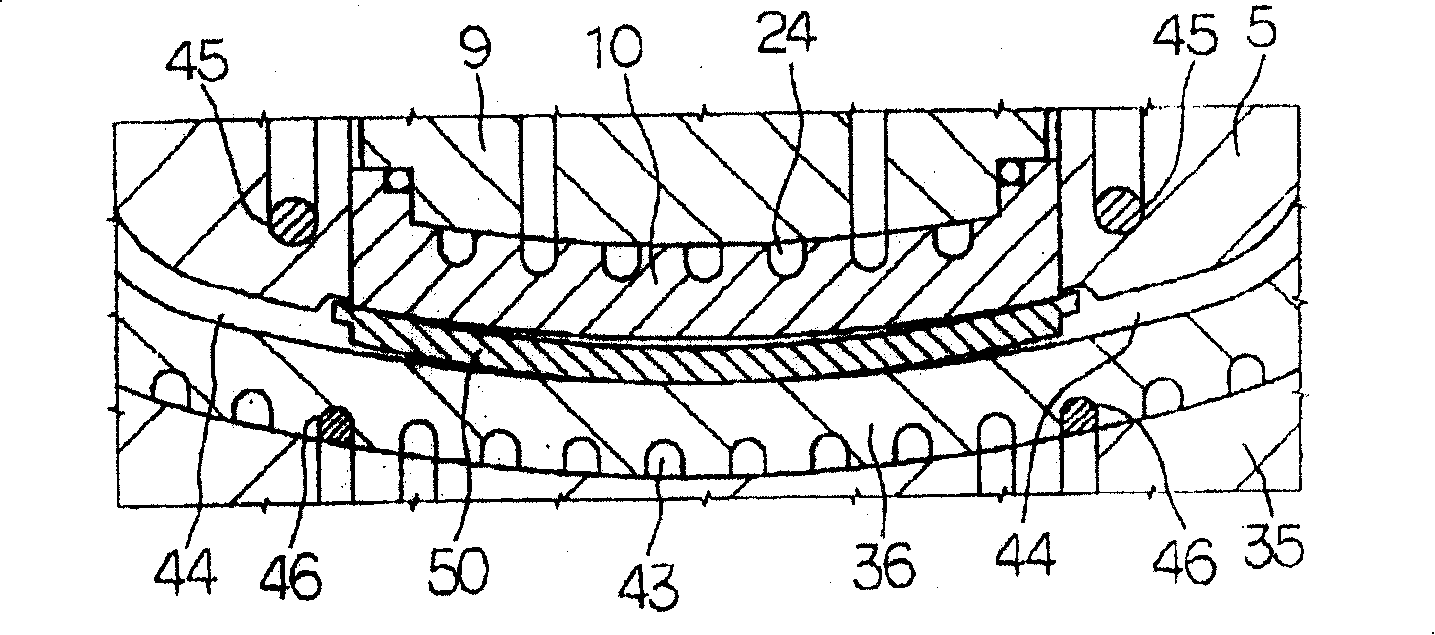

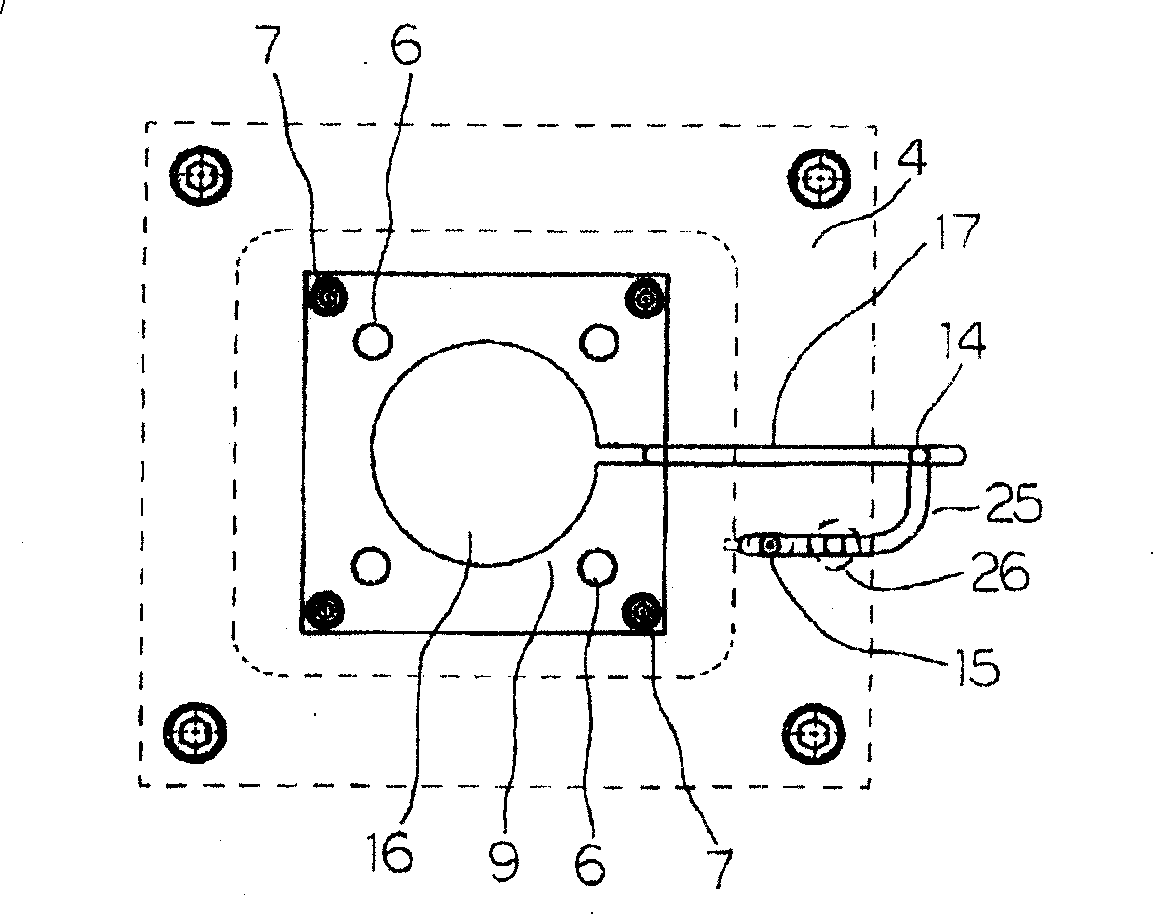

[0112] Below, according to Figure 1 to Figure 9 , to describe the first embodiment for carrying out the present invention. First, according to Figure 1 to Figure 4 , illustrating the overall structure of the mold. figure 1 It is a fixed-side assembly mounted on a fixed platen (not shown) with bolts. The fixed side assembly 1 includes: the first fixed side base plate (base plate) 2 positioned at the top; the second fixed side base plate 3 fixed on the first fixed side base plate 2 by screws; The bottom plate 3 is connected or separated from the fixed side third bottom plate 4; the male die (Male Die) 5 is fitted in the recess of the fixed side third bottom plate 4 and fixed on the fixed side third bottom plate 4; the bushing base 9 , it runs through a plurality of support rods 7 with heads and the lower ends of these support rods 7 are fixed on the third bottom plate 4 on the fixed side, and the bushing base 9 can be placed on the opening of the third bottom plate 4 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com