Method and device for preventing load impacting in crane hook lifting process

A technology of cranes and hooks, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of high speed of load movement, short safety distance, equipment damage, etc., and achieve the effect of eliminating the influence of inertia and preventing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

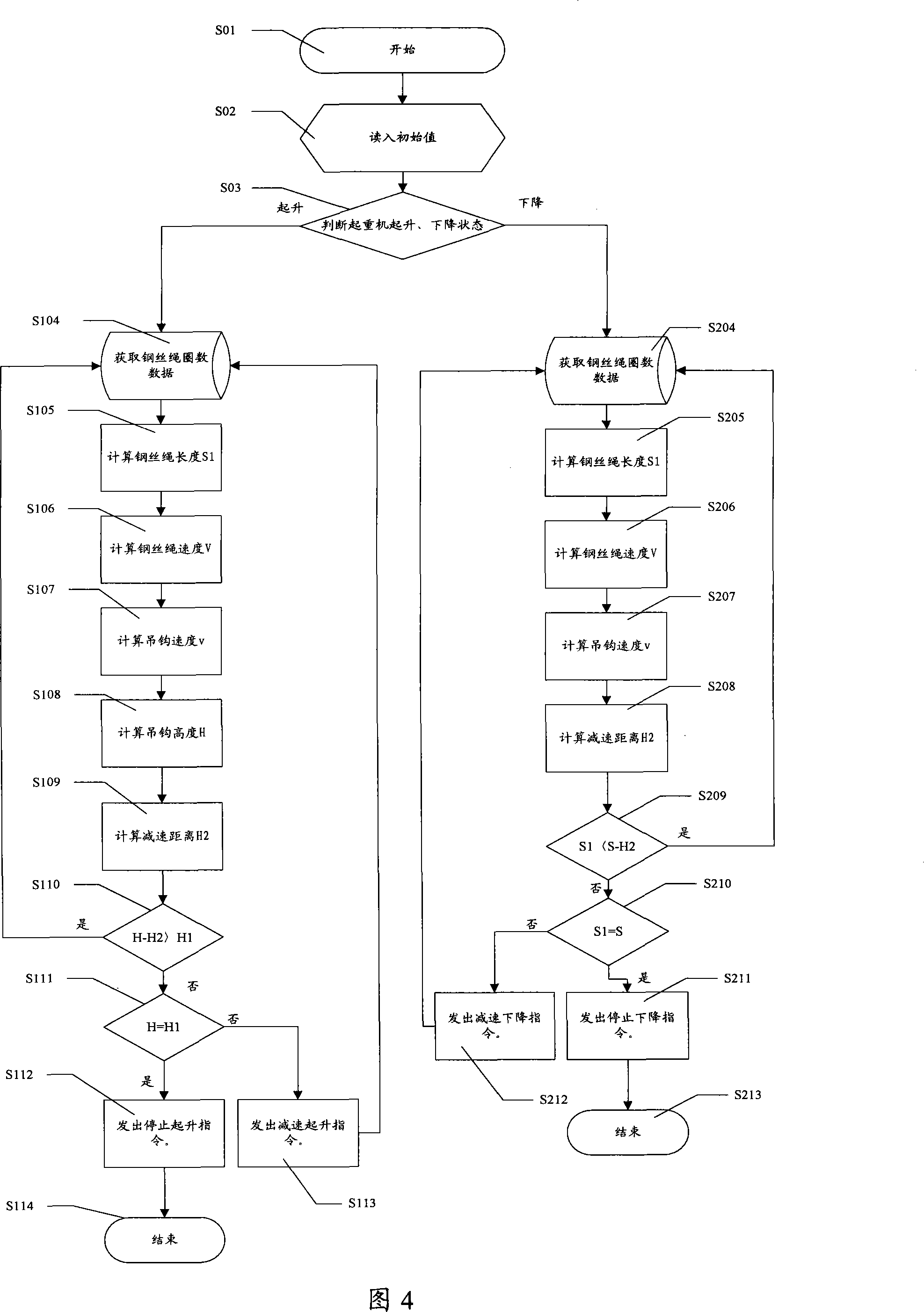

[0047] For the convenience of discussion, the relevant symbols are defined below.

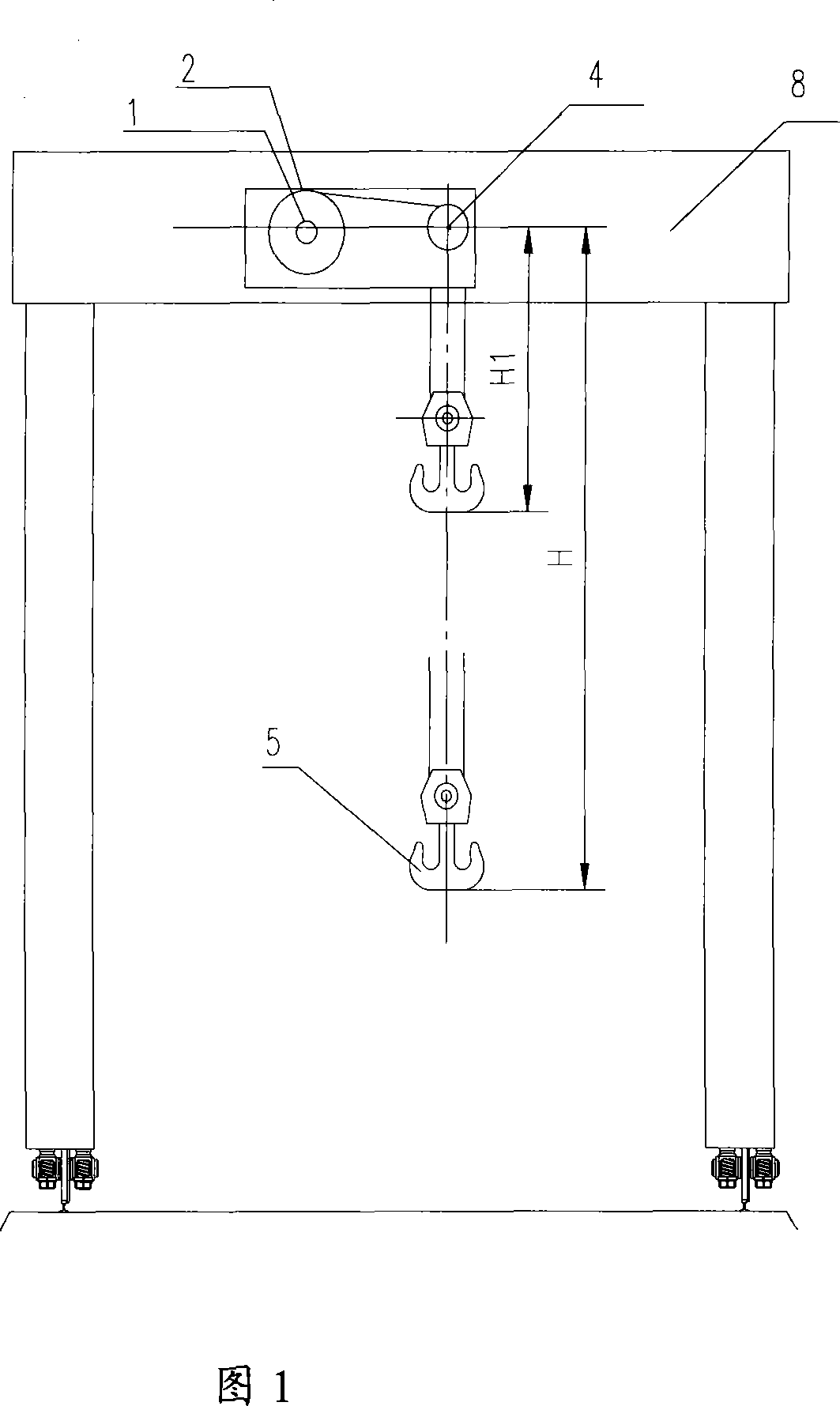

[0048] Referring to Fig. 1, this figure is the structural diagram of the gantry crane of the present invention. For gantry cranes: the hook height H is the actual height from the hook 5 to the center of the lifting pulley block 4; the hook limit height H 1 , is the actual height from the center of the lifting pulley block 4 when the hook 5 is at the upper limit position.

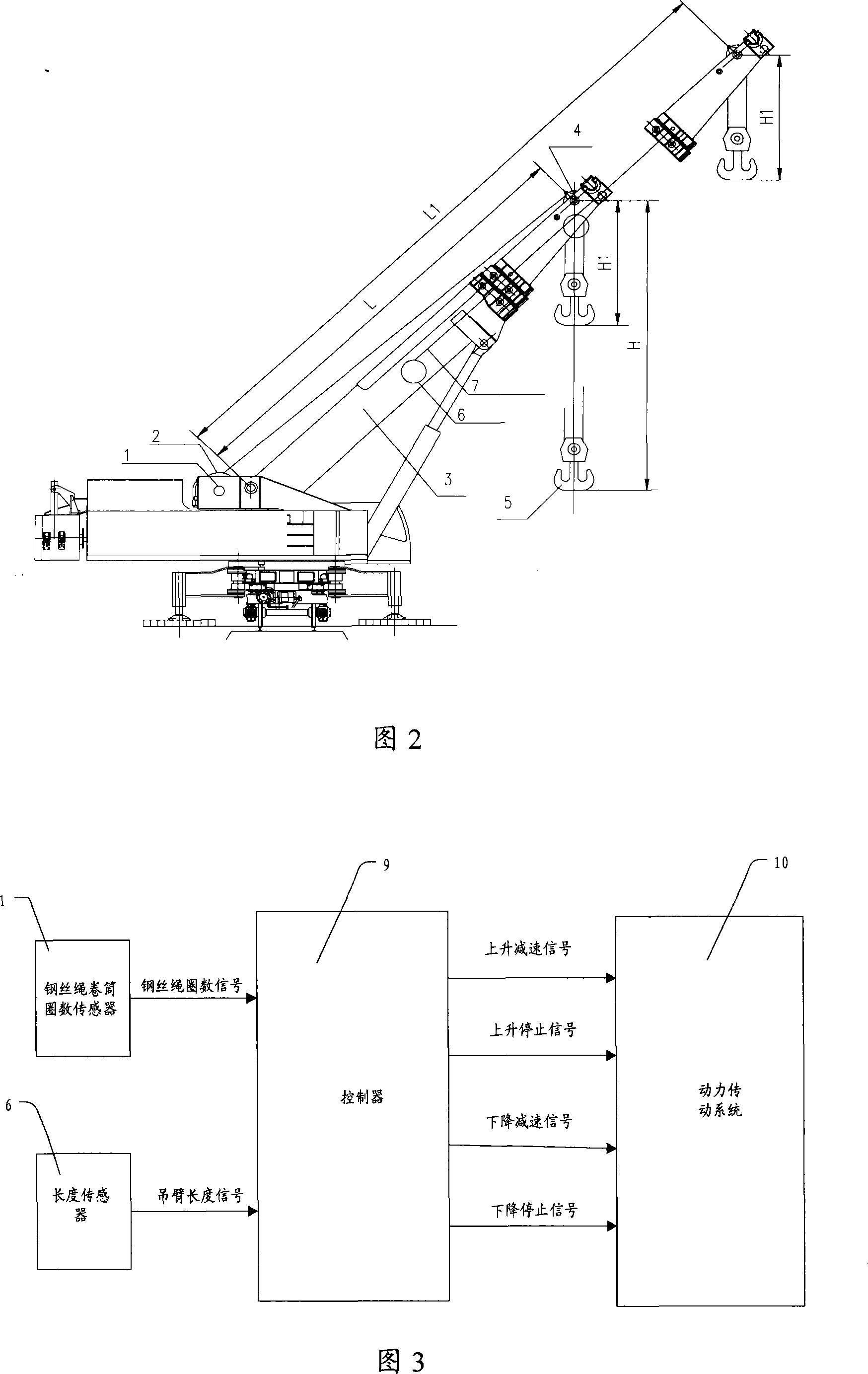

[0049] Referring to Fig. 2, this figure is a structural diagram of the jib crane of the present invention. For jib cranes: the hook height H is the actual height from the hook 5 to the center of the lifting pulley block 4; the hook limit height H 1 , is the actual height from the center of the lifting pulley block 4 when the hook 5 is at the upper limit position; the original length of the boom is the length when the boom 3 is not extended; the length L when the boom is extended 1 , is the length when the boom 3 is stretch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com