Attached lifting scaffold trolley type inclining-proof device and method of use thereof

A technology of attaching lifting and scaffolding, which is applied to the scaffolding of house structure support, house structure support, house structure support, etc. It can solve the problems of easy slipping, low safety factor, and unstable fastener connection, etc., so as to ensure the installation and use effect , Enhanced anti-shear ability, convenient relative movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

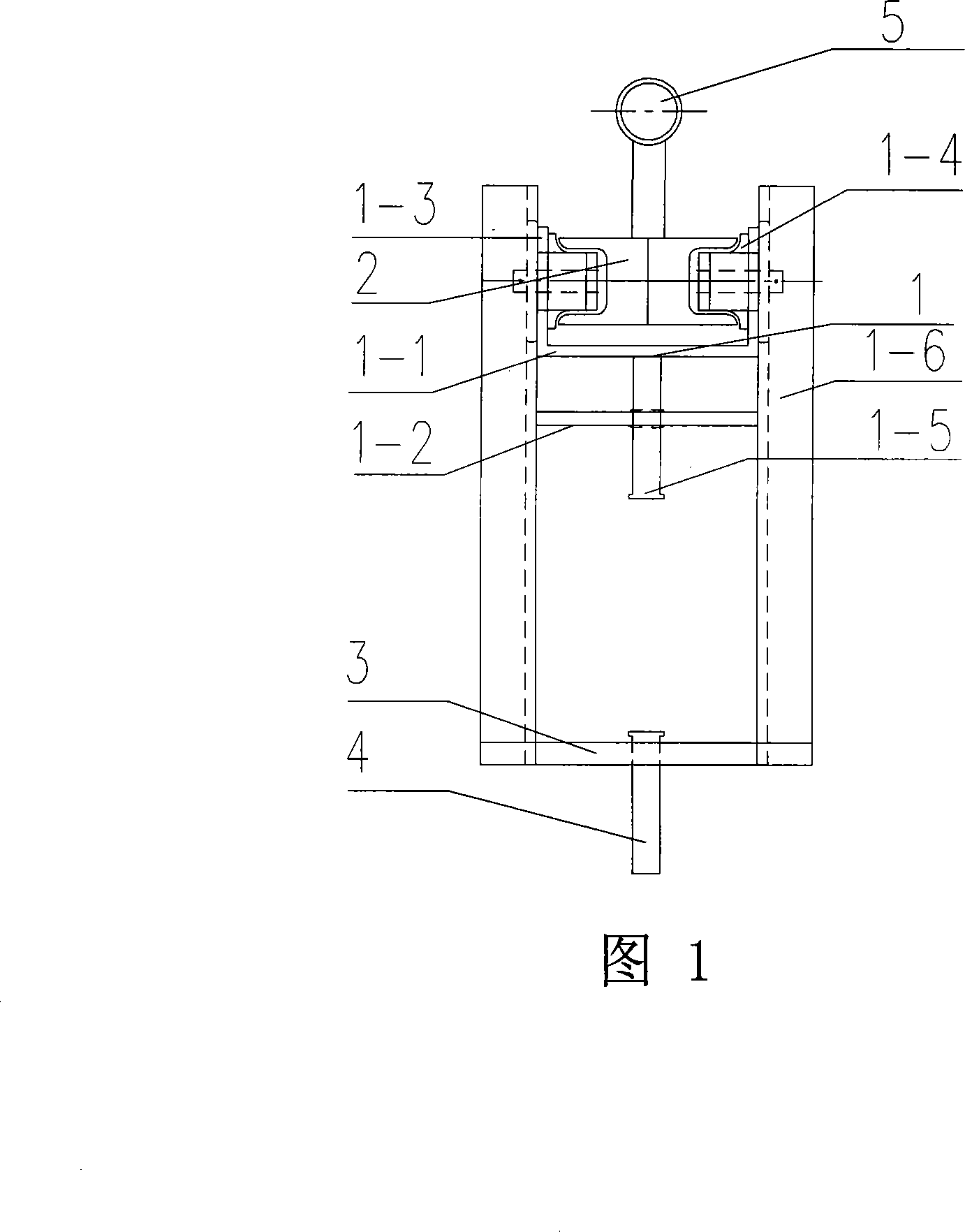

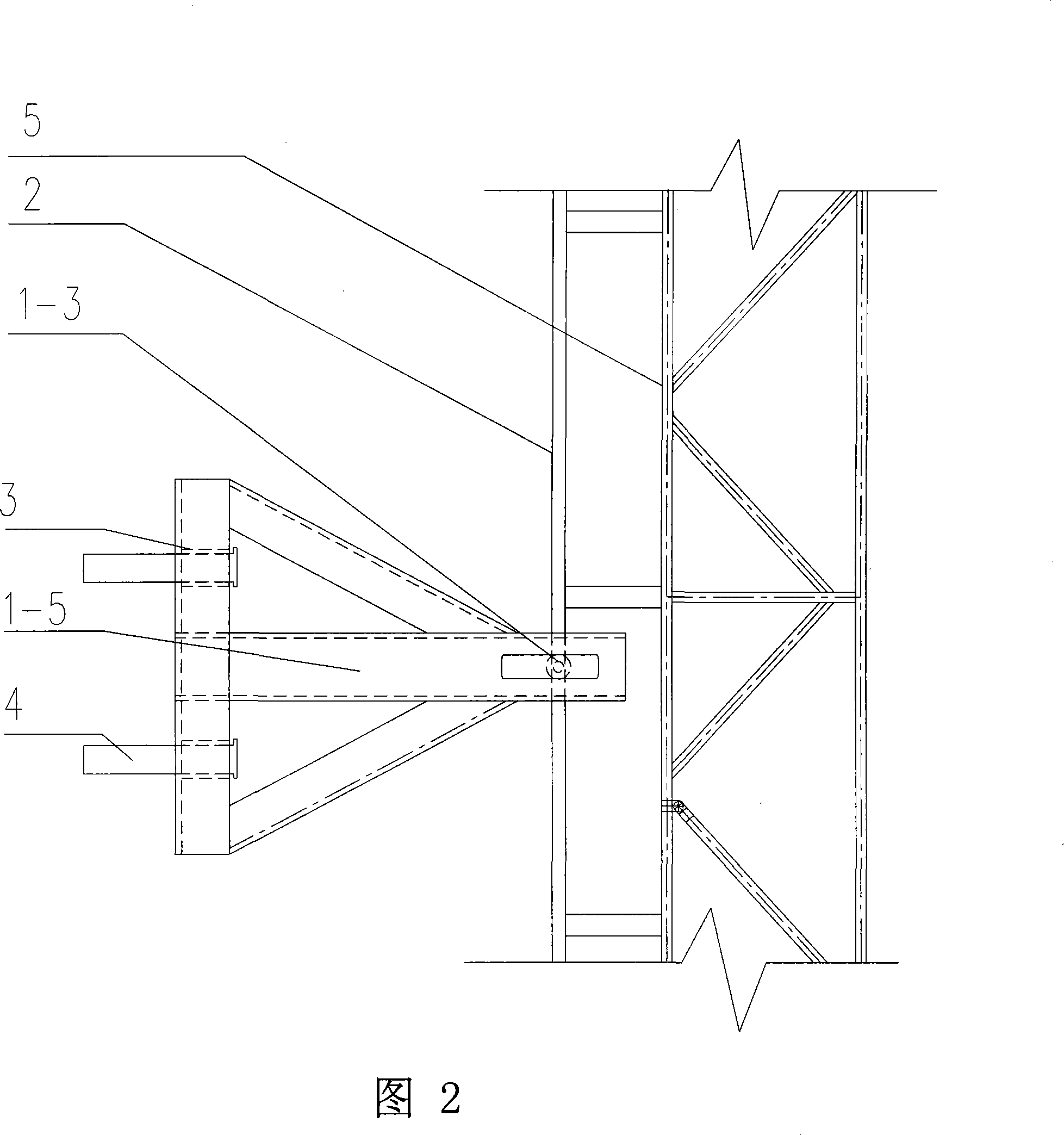

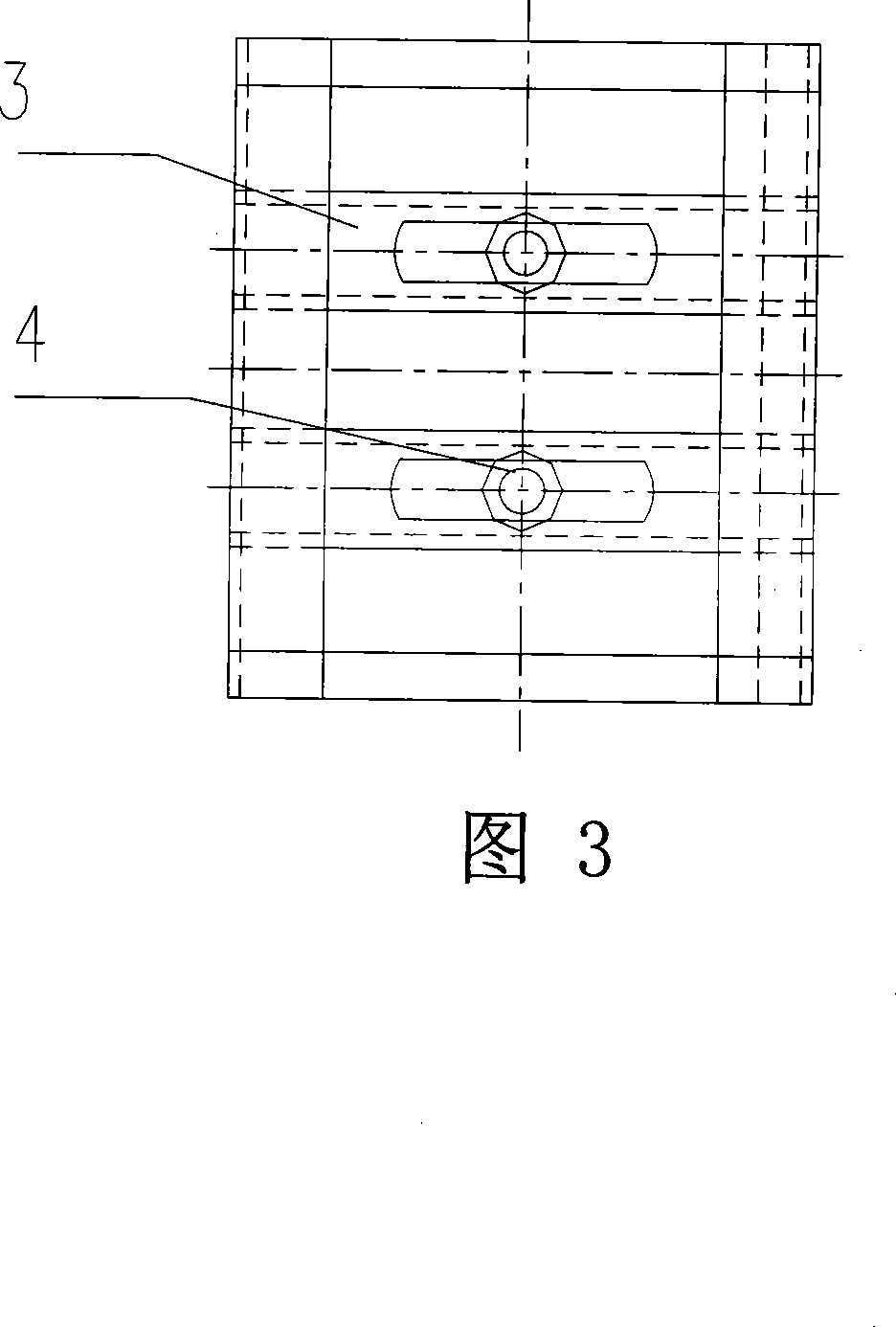

[0029] Example 1: An engineering company constructs a building with a total of 34 floors, the standard floor height is 3.00m, and the roof height is 109.72m, all of which adopt frame shear wall structure. Standard floor (7.22m to 109.72m) floors use attached lifting scaffold construction, all adopt the anti-rolling device of the present invention. Its structure is shown in Figures 1-3: the anti-tilt track 2 is No. 10 I-beam, and the structure of the anti-tilt component 1 is: two M24 wall-through bolts 4 pass through the wall and will be attached to the wall and the building The object connection plate 3 is fixed, and is fixed with the support 1-6 of two horizontal overhangs on the building connection plate 3, is respectively placed on both sides of the anti-tilt track 2, and the support 1-6 is provided with a horizontal groove, and the two support 1 An anti-tilt structure box 1-1 is erected between the -6 and the anti-tilt rail 2 for relative movement up and down, and a pair o...

Embodiment 2

[0045] An engineering company constructs commercial housing. The project is a frame shear wall structure with a construction area of 56,000 square meters and a roof height of 89m. The 1-3 floors are podium buildings, 26+1 floors above ground, 1 floor underground, and 4-26 floors of standard floors. From the standard floor 4-26, use the attached lifting scaffold for construction. The shape of the building is relatively complicated, and there are arcs, corners, balconies, and pick-up boards around the building, which brings certain difficulties to the construction of the outer frame. At the arc, the bottom of the anti-tilt component needs to be padded with gaskets, and the connecting steel column is added to the pick plate to make the connection between the frame body and the anti-tilt component have sufficient rigidity to meet the construction requirements.

[0046] The structure of the anti-tilt component is: 6 M24 wall-through bolts 4 pass through the wall to fix the wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com