Printed circuit boards coarse defect image detection method based on FPGA

A printed circuit board, image detection technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of affecting detection efficiency, difficult to determine image differences, slow detection speed, etc., to improve work efficiency and reduce misjudgment and omission of judgment, to achieve the effect of accurate judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

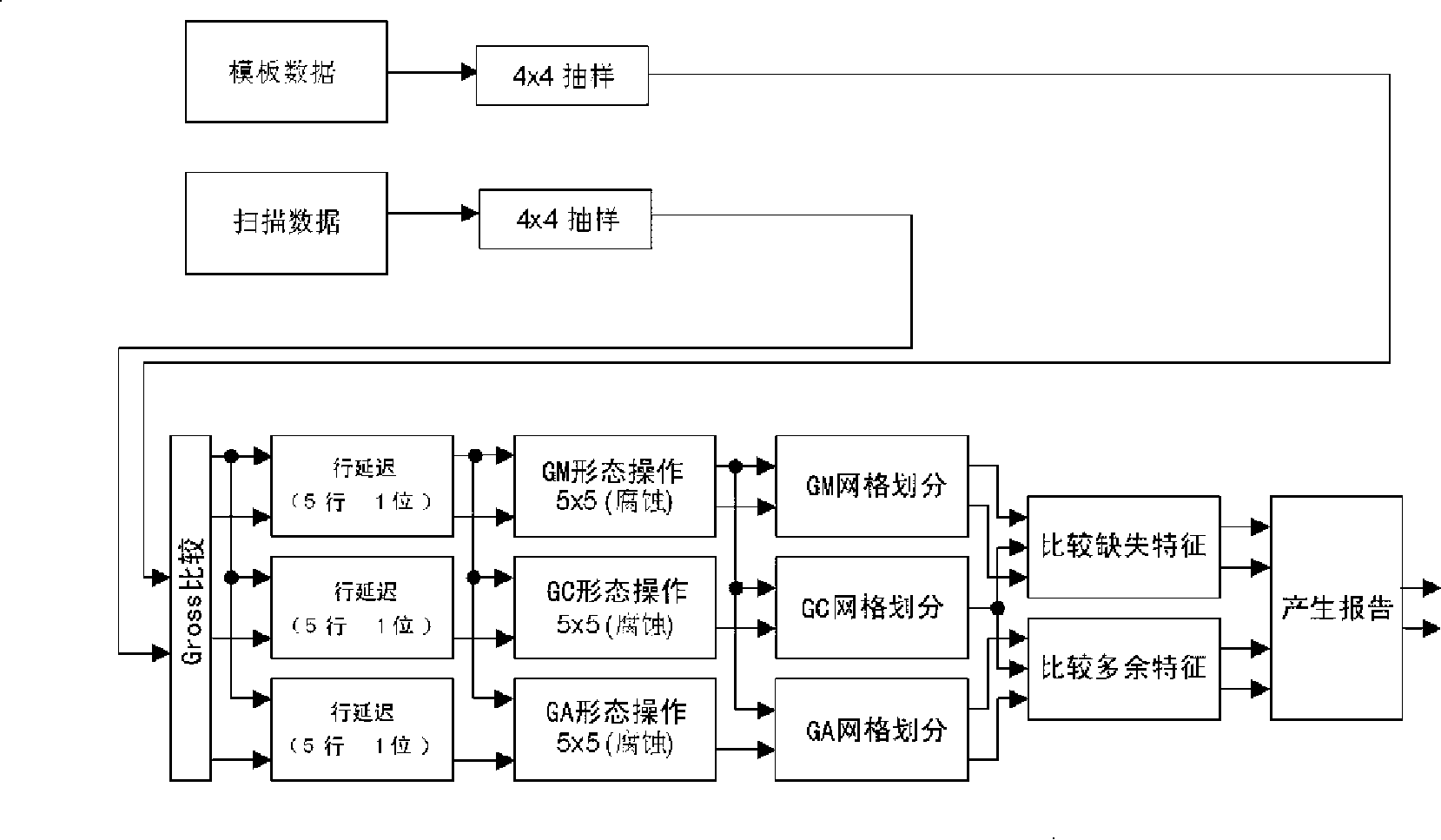

[0032] Embodiment: the present invention realizes algorithm description by using hardware description language VHDL, downloads to FPGA programmable gate array, adopts grid technology to carry out fast and effective analysis, processing to image, guarantees the fast and effective of algorithm and the accuracy of result.

[0033] Figure 6 The flow chart of the novel Gross algorithm based on FPGA provided by the present invention, the method may further comprise the steps:

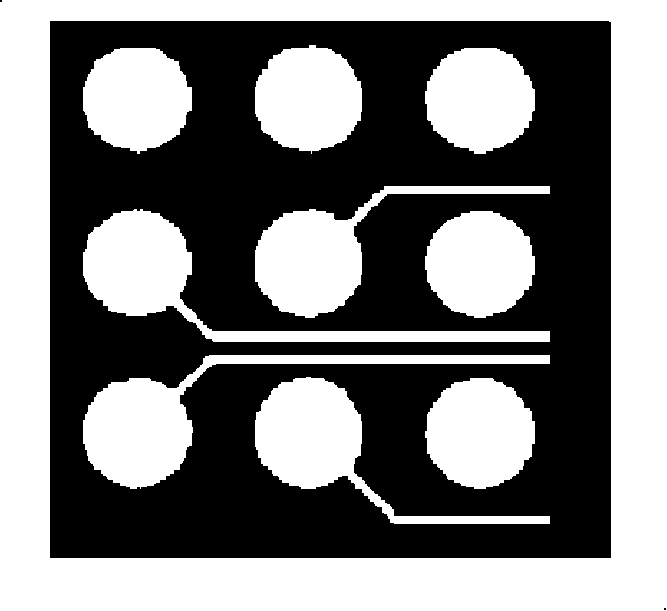

[0034] Step 1: If figure 1 As shown, in the comparison module, input the data stream and parameters, input the preprocessed scanned image data and the template image data with the same angle as the scanned image, and wait for processing.

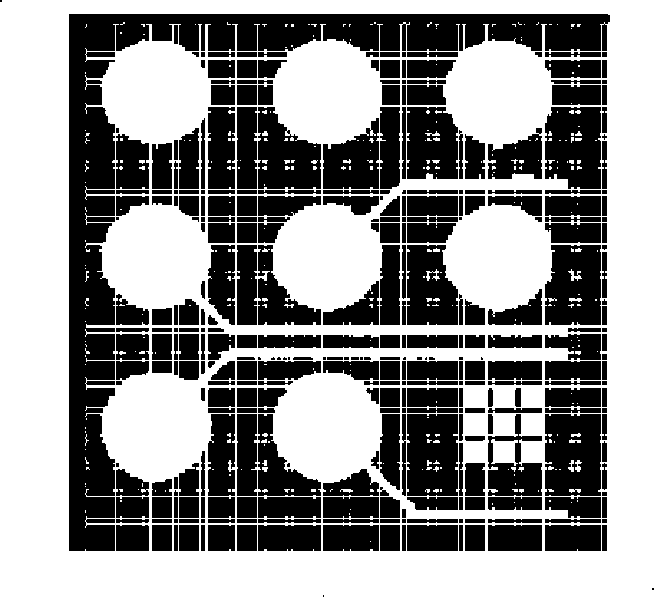

[0035] Step 2: If figure 2 As shown, the scanning data and the template data are respectively subjected to a 4×4 sampling operation, so the algorithm mainly detects large defects, and the subtle features can be ignored, so the image is sampled to reduce the amount of da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com