A brushless automatic control electric machine liquid resistance starter

A technology of starter and hydraulic resistance, applied in the direction of motor generator/starter, liquid resistor, starter of single multi-phase induction motor, etc., can solve problems such as failure to maintain and loss of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

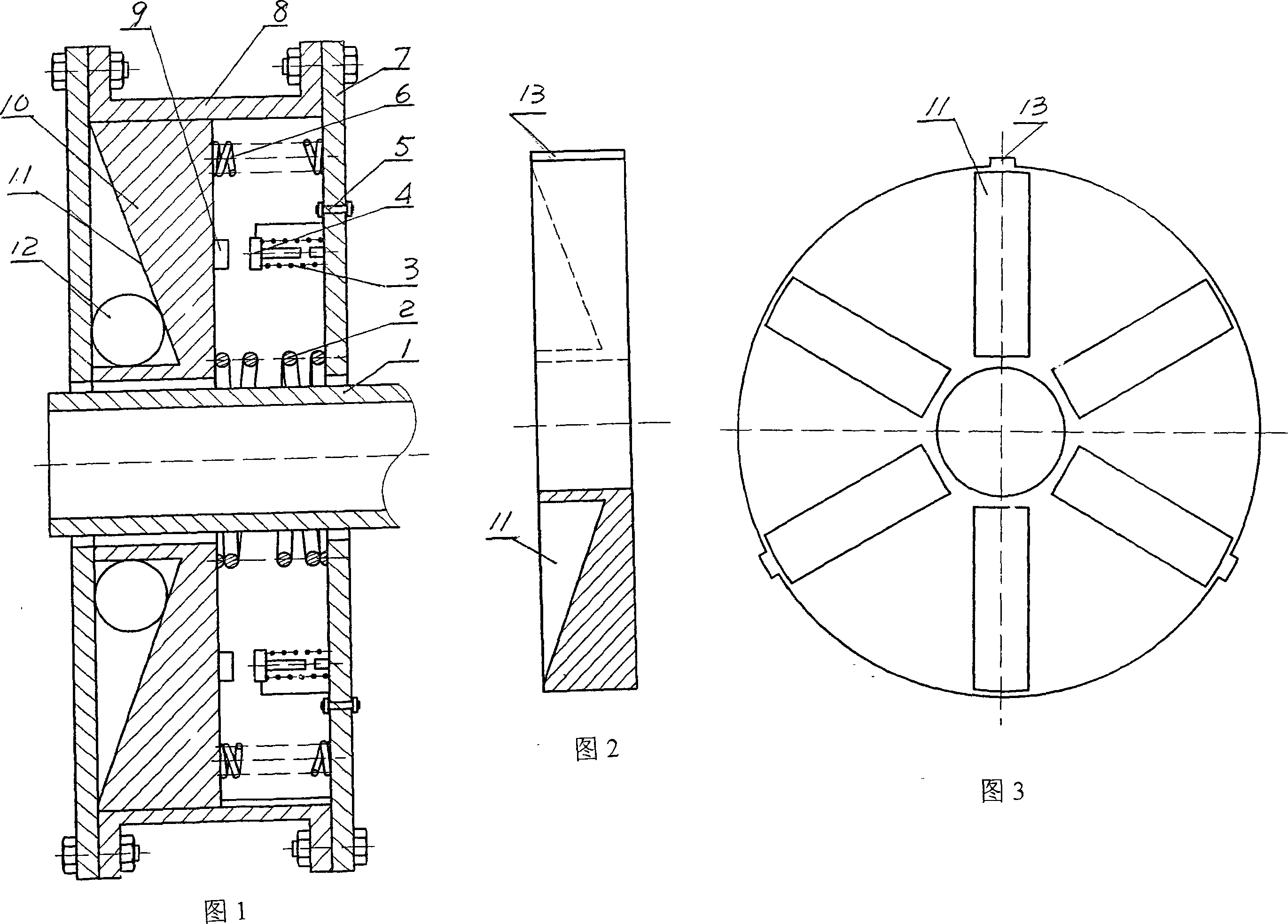

[0005] The present invention solves the problem that the dynamic and static electrodes cannot be taken out from the liquid storage tank and are inconvenient to maintain due to the radial arrangement of the dynamic and static electrodes in the 03112809.2 invention patent. The present invention is provided with a circular star-sealing movable pole plate 10, the central hole of which is movably matched with the rotating shaft 1, and six grooves 11 are evenly distributed along the circumference on one end surface of the movable pole plate, and the bottom surface of the groove is a The inner end is deep and the outer end is shallow, 6 steel balls 12 are placed in the cavity between the groove and the case cover, and 3 axial convex strips 13 are evenly distributed on the outer circular surface of the moving plate and the inside of the case body 8 The longitudinal guide grooves on the surface are slidingly matched, and there are 6 moving contacts 9 evenly distributed on the end surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com