Power generation system of wheel potential energy

A power generation system and wheel technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of destroying the original structure, difficulty in implementation, large volume of shaft end stators and stator clutches, etc., and achieve fuel saving, manufacturing and installation. Easy, huge social economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

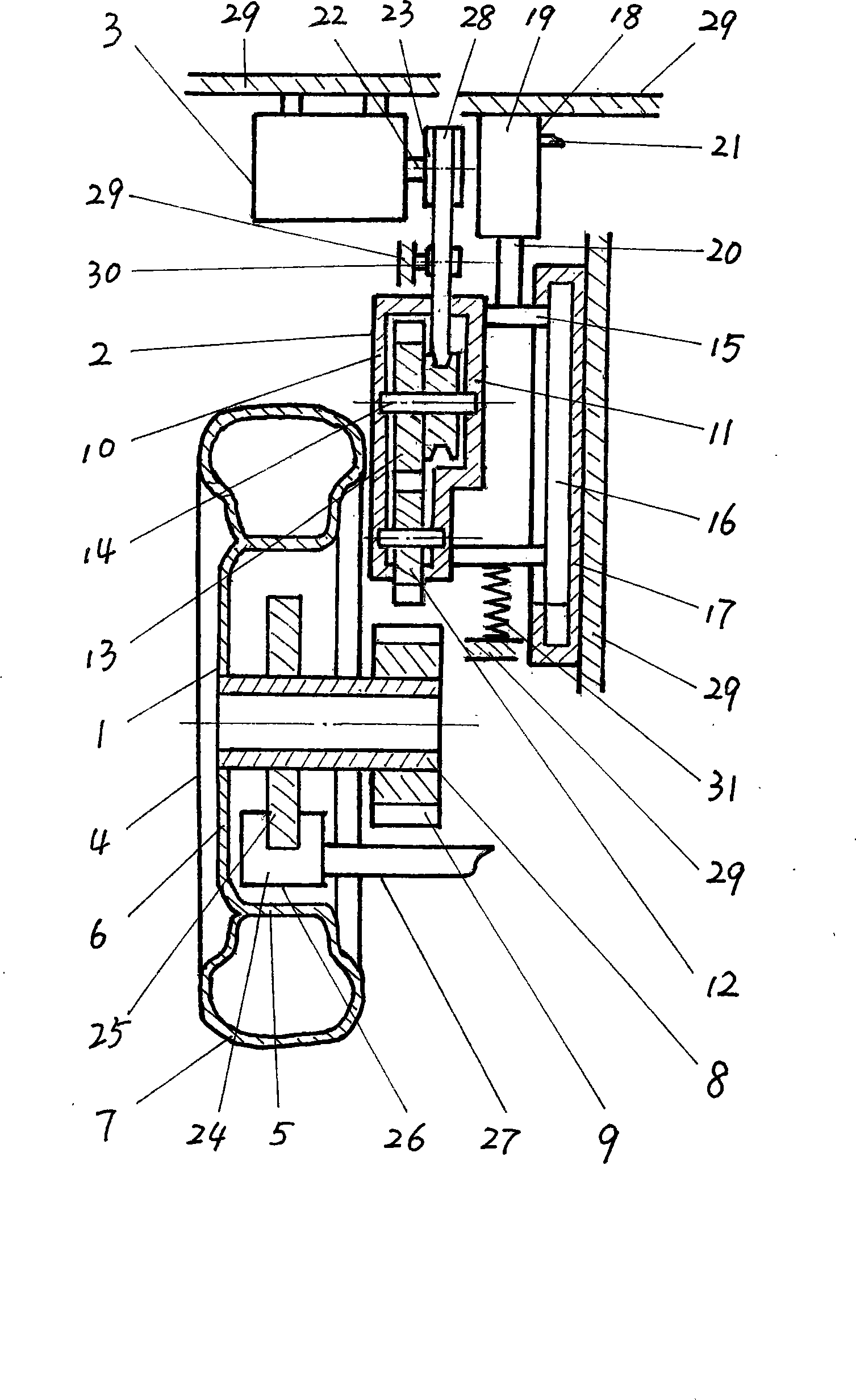

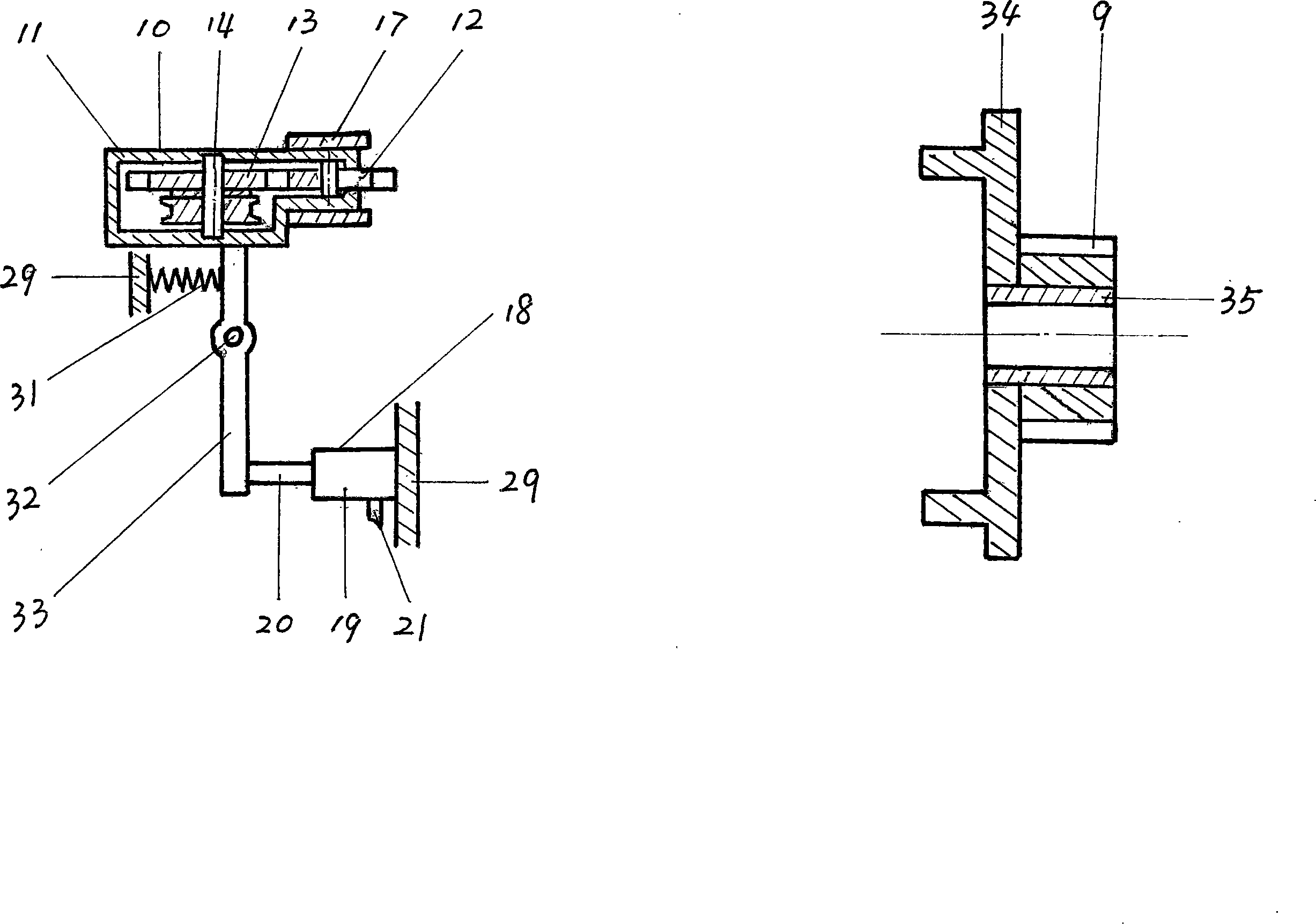

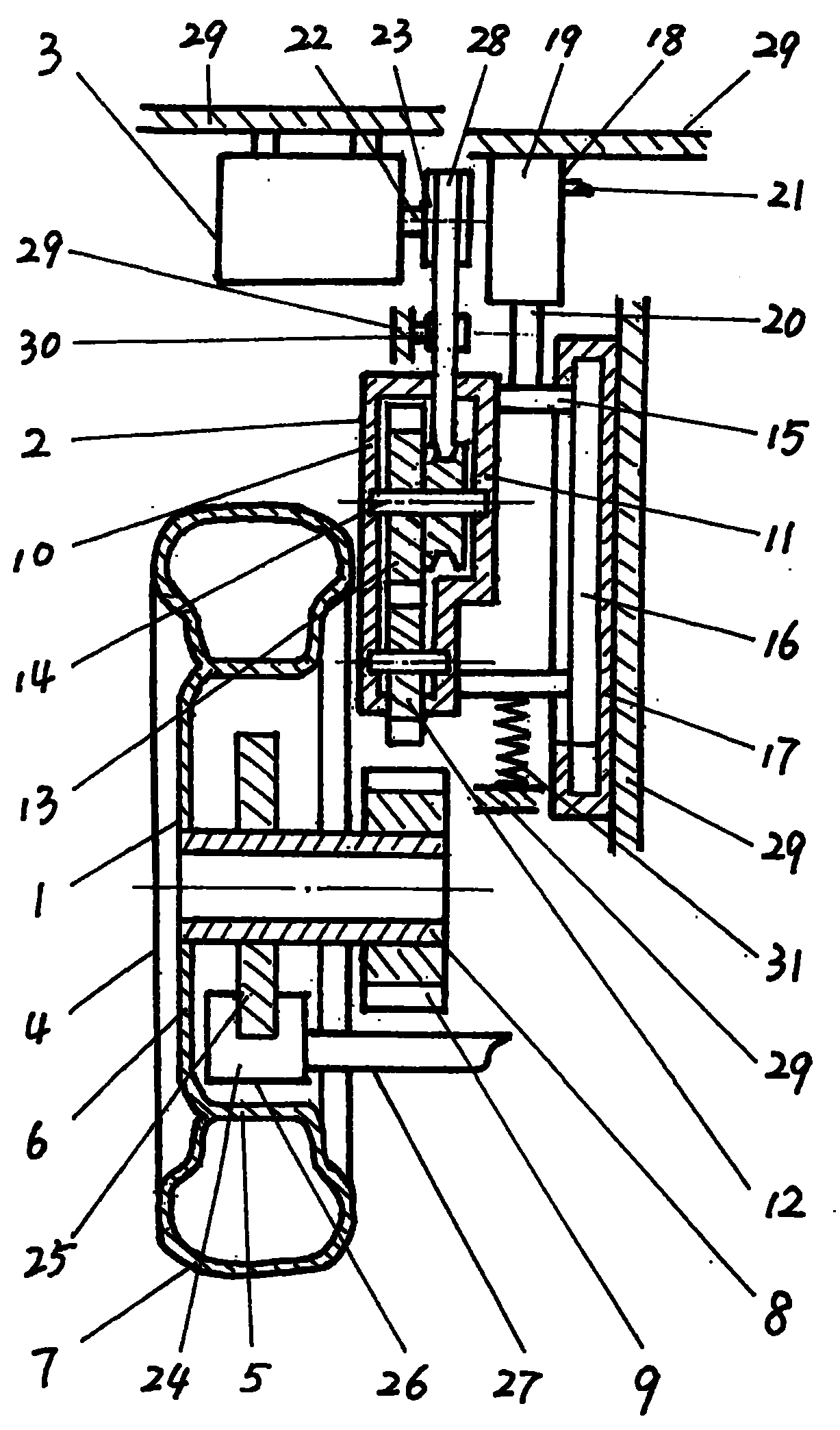

[0015] In Fig. 1, 1 is a wheel potential energy collection device, 2 is a potential energy transmission clutch device, and 3 is a generator. The wheel potential energy collection device 1 is composed of a wheel 4 , a mining wheel 9 and a disc brake 24 . The wheel 4 is composed of a rim 5 , spokes 6 , tires 7 and a hub 8 . On the wheel hub 8, the mining wheel 9 is installed. The disc brake 24 is composed of a disc 25 , a caliper 26 and a caliper arm 27 . Brake caliper 26 is installed on one end of brake caliper arm 27, and the other end is installed on the vehicle frame chassis or on the axle. The driving wheel 9 is a gear, and if necessary, it can also be installed on the rim 5 of the wheel 4, the spoke 6, the brake disc 25 or on the brake drum. The potential energy transmission clutch device 2 is made up of a transmission wheel frame 10 , a slide groove 17 and a clutch 18 . The drive wheel frame 10 is composed of a drive wheel housing 11, a drive wheel 12, a drive main wh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap