Conveying system

A technology for handling systems and power cords, applied in the field of handling systems, which can solve the problems of inconvenient replacement or maintenance of collector rails, generation of dust, wear of components, etc., and achieve the effects of good dust removal, cleanliness maintenance, and simplified components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

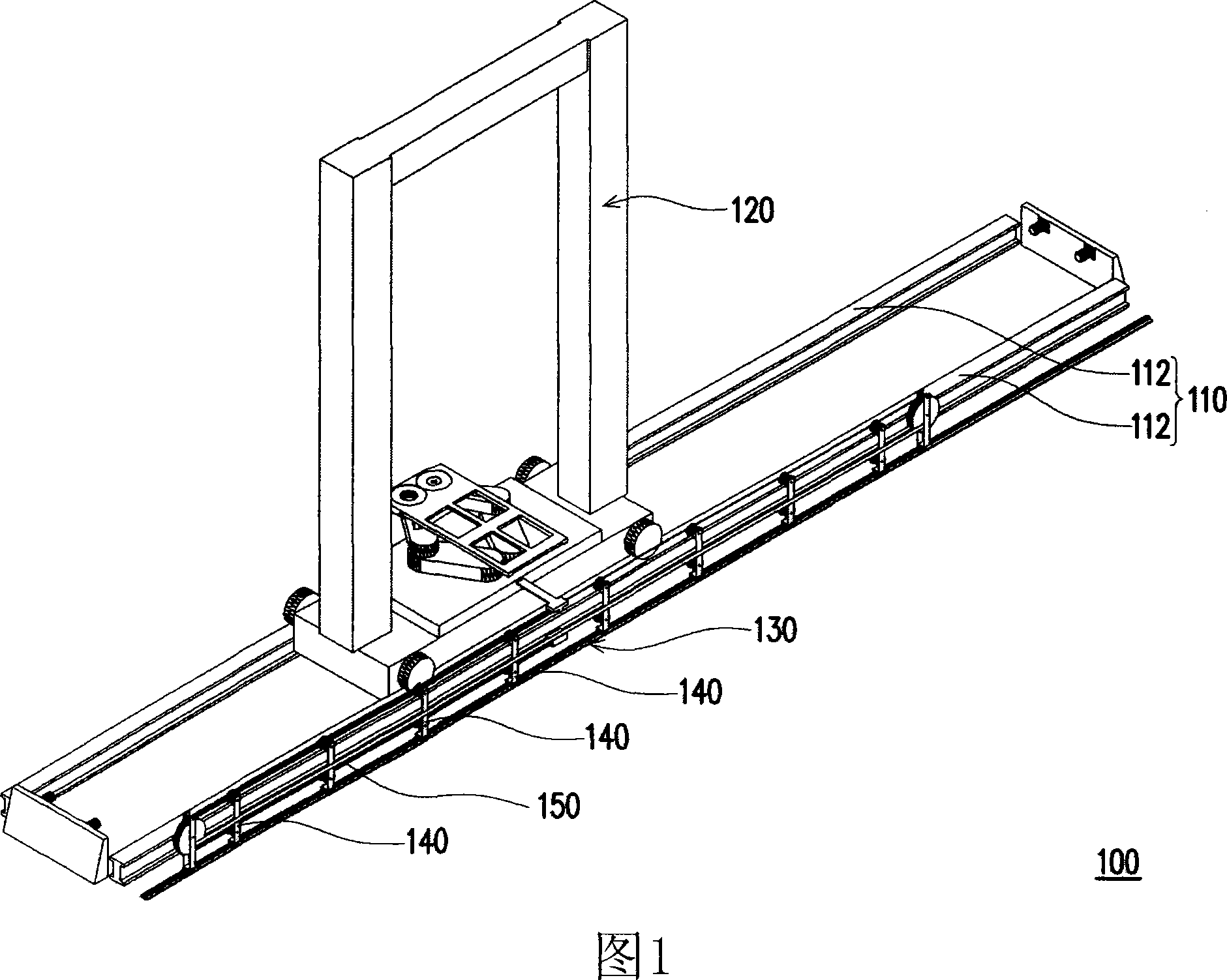

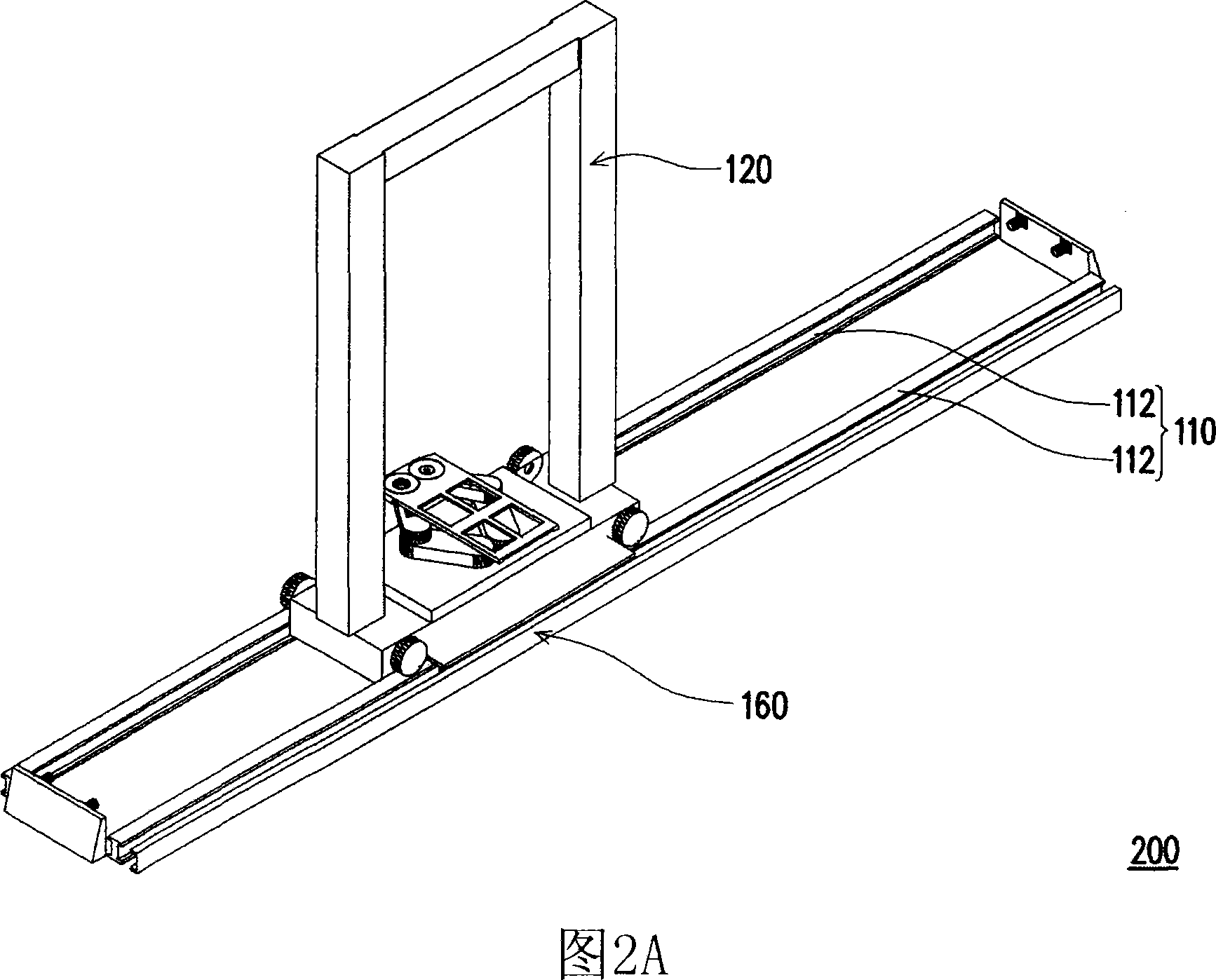

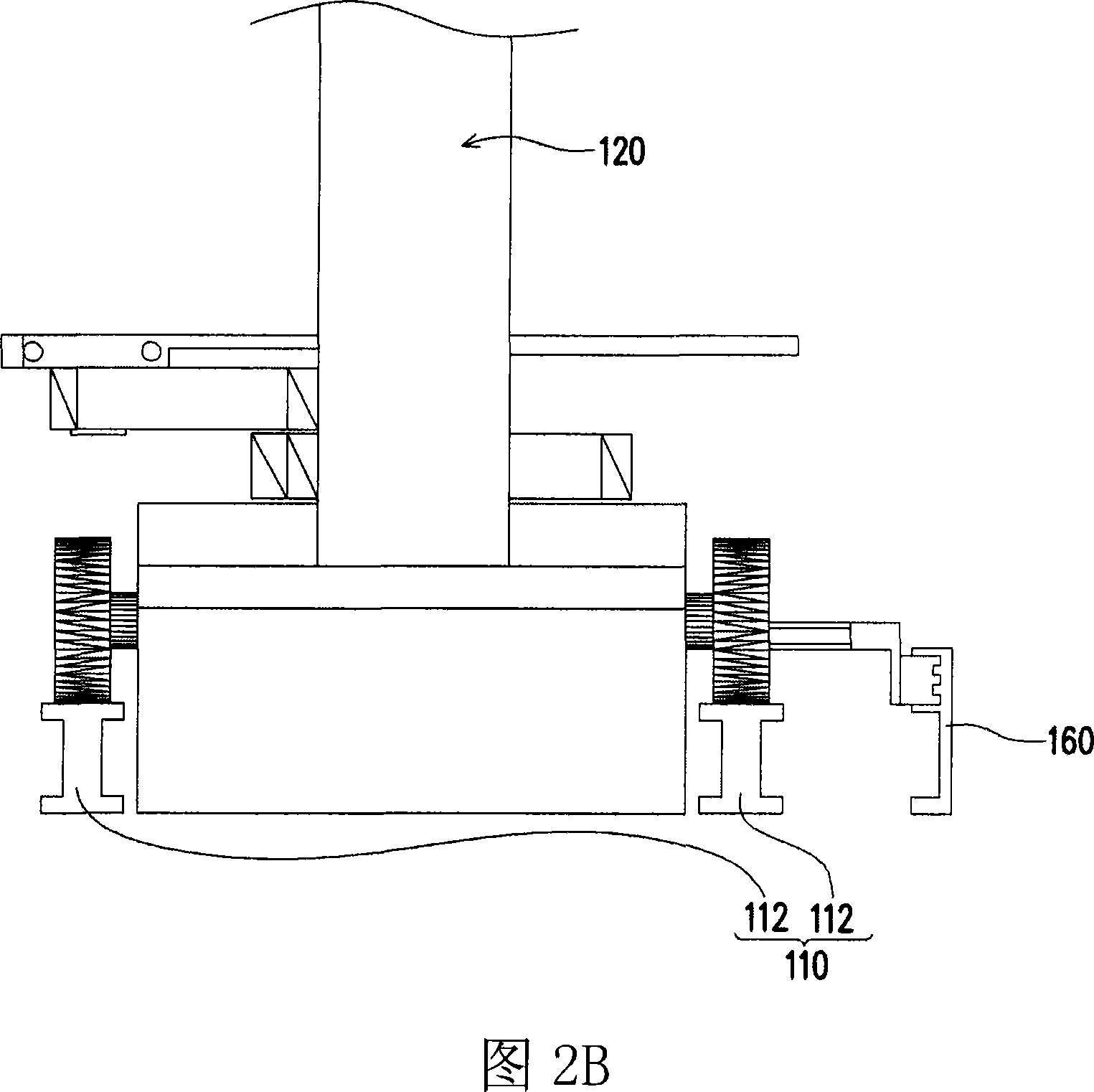

[0033] FIG. 3A is a schematic diagram of a transport system of the present invention, and FIG. 3B and FIG. 3C are partial schematic diagrams of FIG. 3A . Please refer to FIG. 3A , FIG. 3B and FIG. 3C at the same time. The transportation system 300 includes a base 310 , a crane 320 , a power cord receiving device 330 and a power cord 340 . The base 310 has a track 312 . The crane 320 is located on the base 310 and travels along the track 312 . The power cord storage device 330 is disposed at one end of the track 312 , and the power cord 340 is stored in the power cord storage device 330 . In addition, the power line 340 is electrically connected to the crane 320 to supply power to the crane 320 .

[0034] When the power cord 320 provides power to the crane 320 to move the crane 320, since the power cord 340 needs to be electrically connected to the crane 320 to supply power, the power cord 340 needs to cooperate with the crane 320 to move, so as to avoid the power cord 340 br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com