Apparatus for positioning mine prop by increasing pressure

A ore pillar and pressure technology, applied in pillars/supports, mining equipment, mine roof supports, etc., can solve problems such as high costs, and achieve the effect of low manufacturing cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

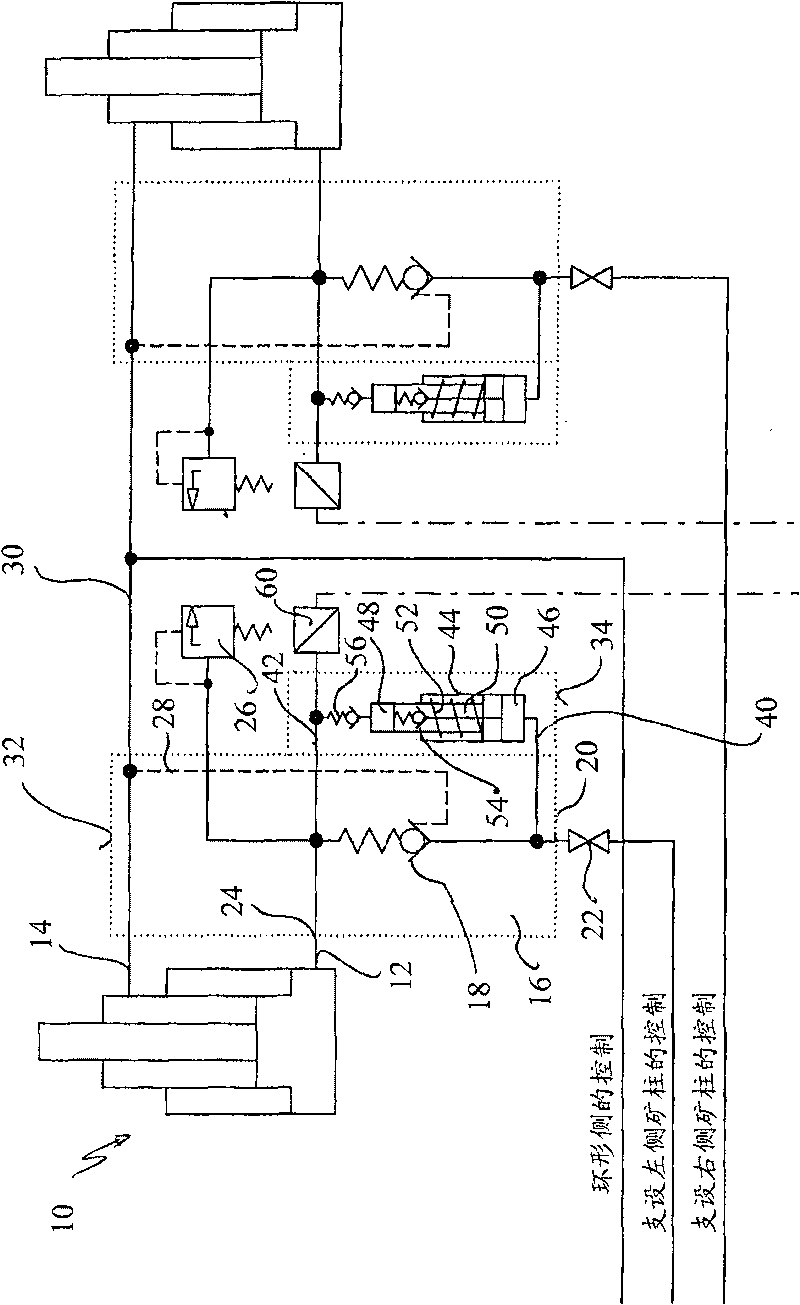

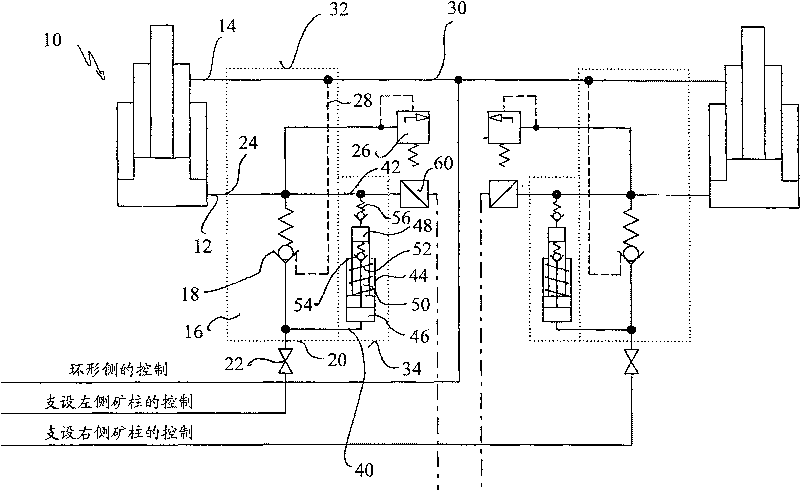

[0018] The figure shows a pillar 10 of a face support frame with a piston-side connection 12 for supporting the pillar and a ring-side connection 14 for recovering the pillar. The control of the pillar 10 takes place via a pillar valve 16 which has an openable non-return valve 18 inside it. The openable non-return valve 18 is closed in the direction of the inlet 20 of the pillar valve 16 , which is provided with an electrohydraulic abutment pressure via a plug 22 . The outlet 24 of the pillar valve 16 is connected to the piston-side connection 12 of the pillar 10 and is connected to an openable check valve 18 which is closed in the direction of the inlet 20 . A pressure relief valve 26 is additionally connected to the outlet-side connection 24 of the pillar valve. The openable non-return valve 18 is connected via a control channel 28 to the annular-side port 14 of the pillar 10 , wherein this port is connected to the electrohydraulic control unit via a line 30 , via which the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com