Geomechanics model production method based on compacting work recombination action function reverse control principle

A technology of compound action and control principle, applied in the field of geomechanical models, can solve problems such as parameter distortion, and achieve the effect of ensuring uniformity and improving the quality of model production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] (Take two model tests as an example)

[0026] 1. Model test 1

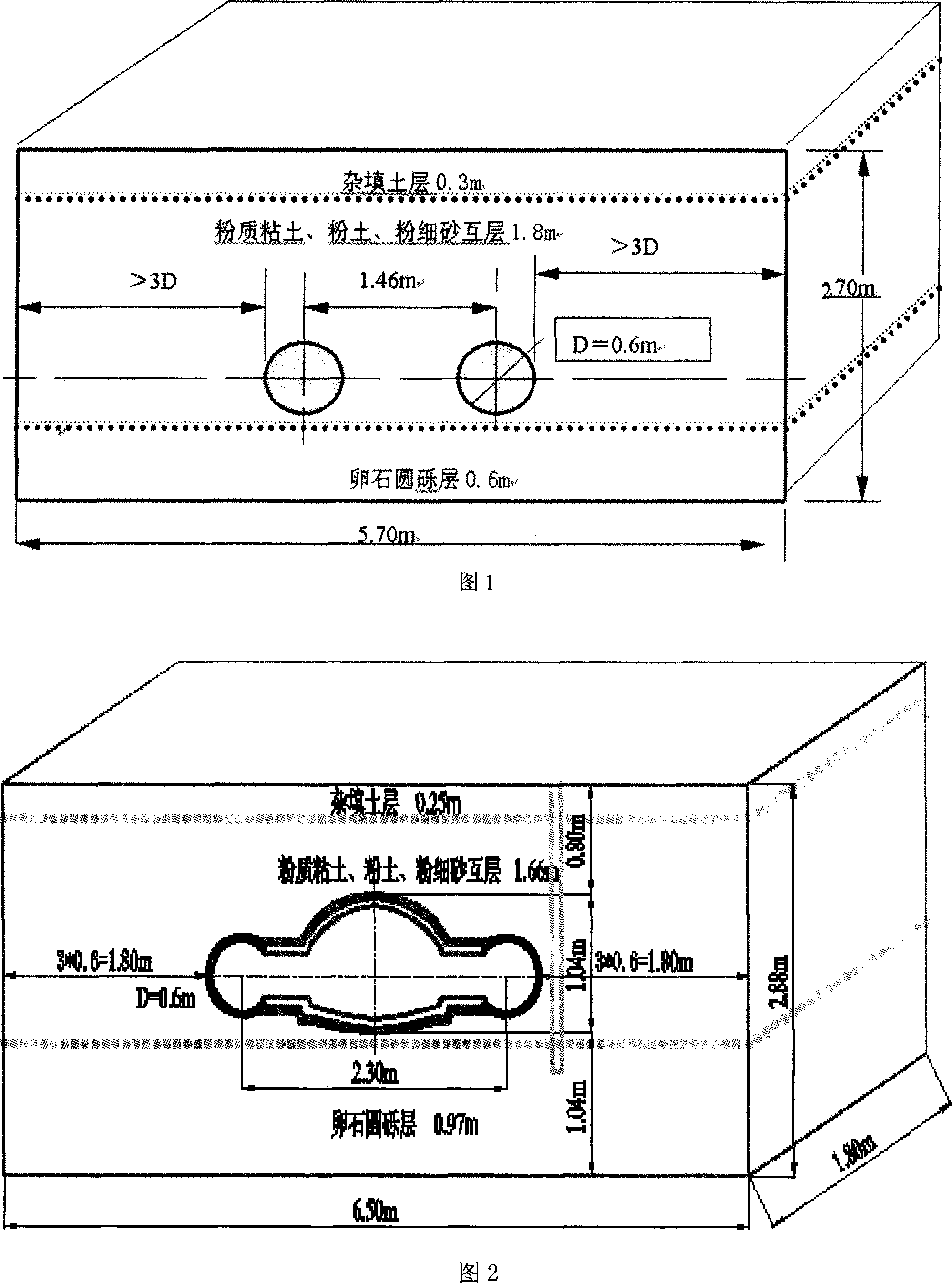

[0027] Experiment 1 is a simulation of the construction process of the crossing section of the shield subway tunnel. The size of the model is 6.2m×1.8m×2.7m (L×W×H), as shown in Figure 1.

[0028] 2. Model test 2

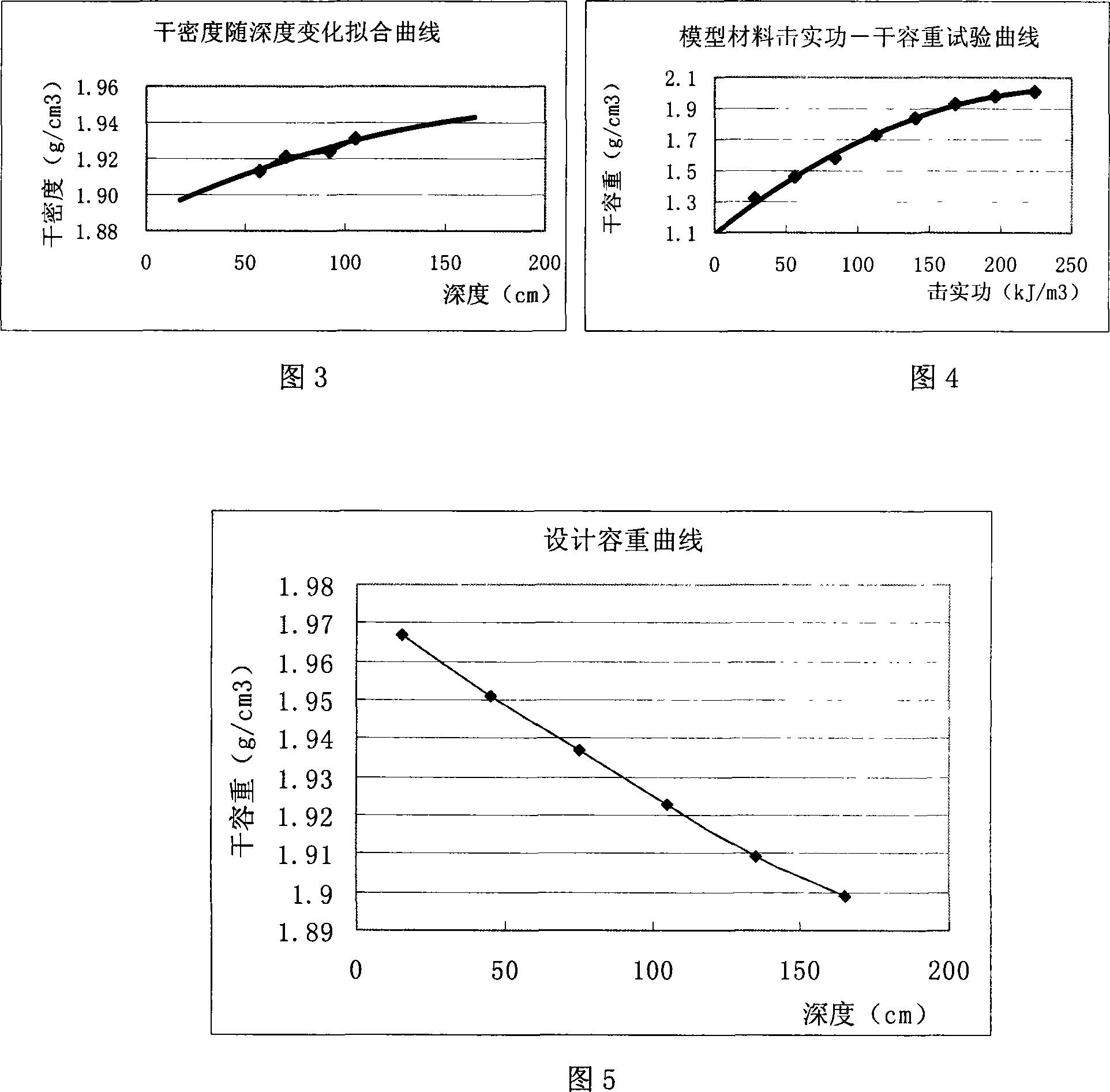

[0029] Experiment 2 is a simulation study on the construction process of the shield tunnel extension subway station. The final size of the model is determined to be 6.5m×1.8m×2.88m (L×W×H), see Figure 2 for details.

[0030] in situ test

[0031] Model test 1 was filled with the traditional constant volume control method, and after the filling was completed, an in-situ sampling test of bulk density was carried out. The sampling data is plotted and fitted as shown in Figure 3. From the fitting data, it can be seen that the bulk density of the model gradually increases from top to bottom. The formula (1) is obtained by fitting the quadratic polynomial, where ρ is the dry density inside the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com