Slide fastener with automatic stop device

An automatic stop device and zipper puller technology, applied in the field of zipper pullers, can solve problems such as difficult and cheap production, and achieve the effects of simplifying assembly operations, high-speed assembly, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

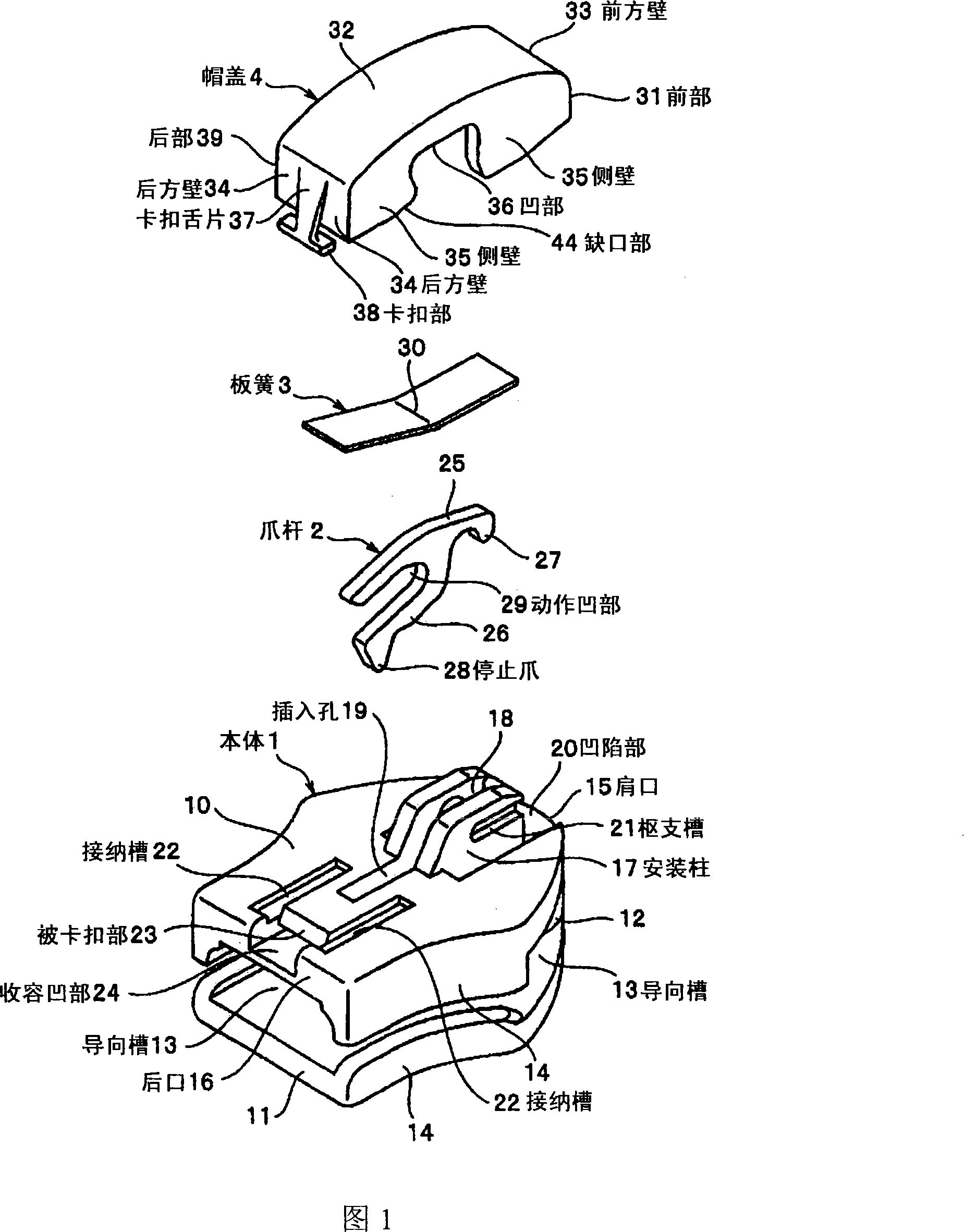

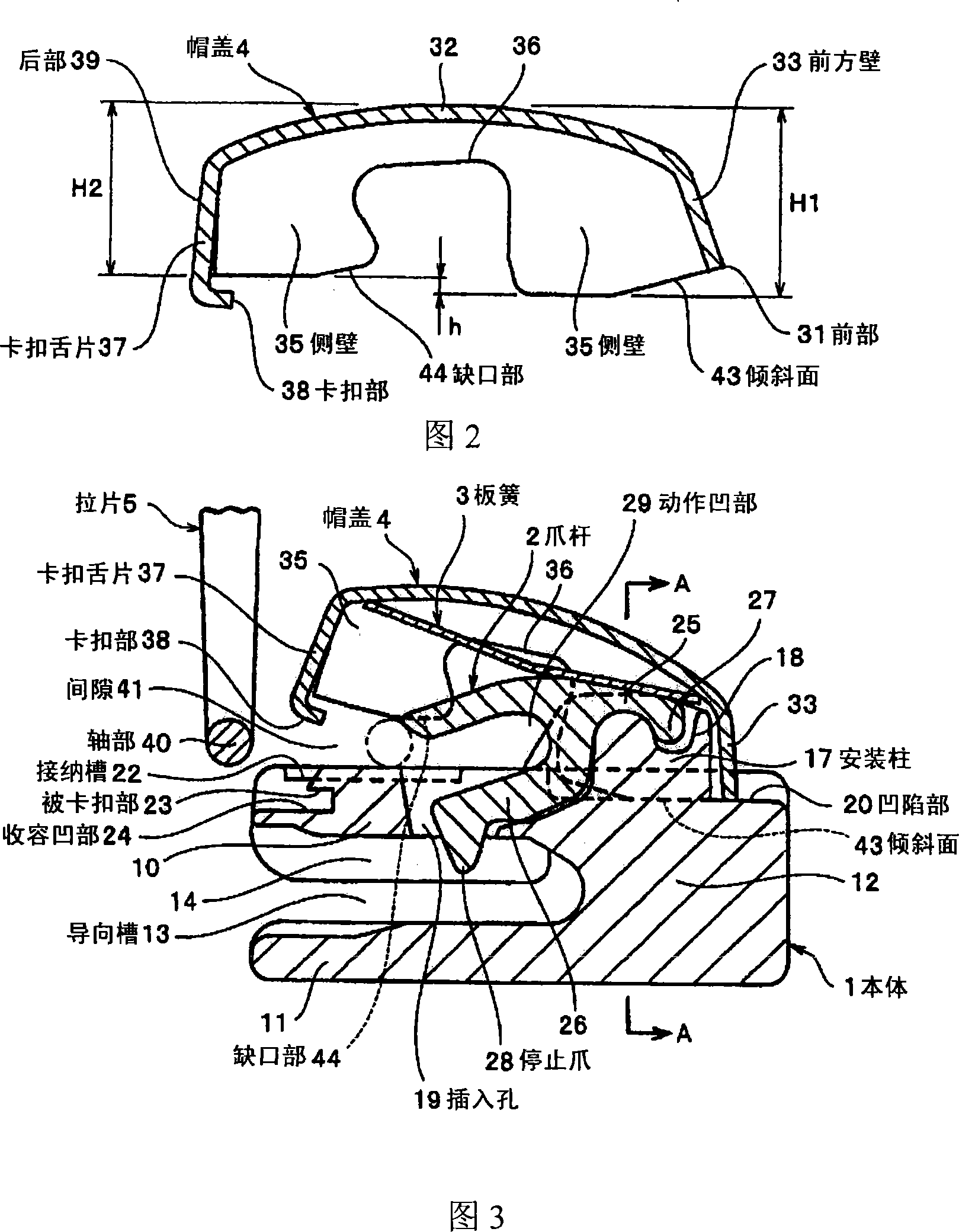

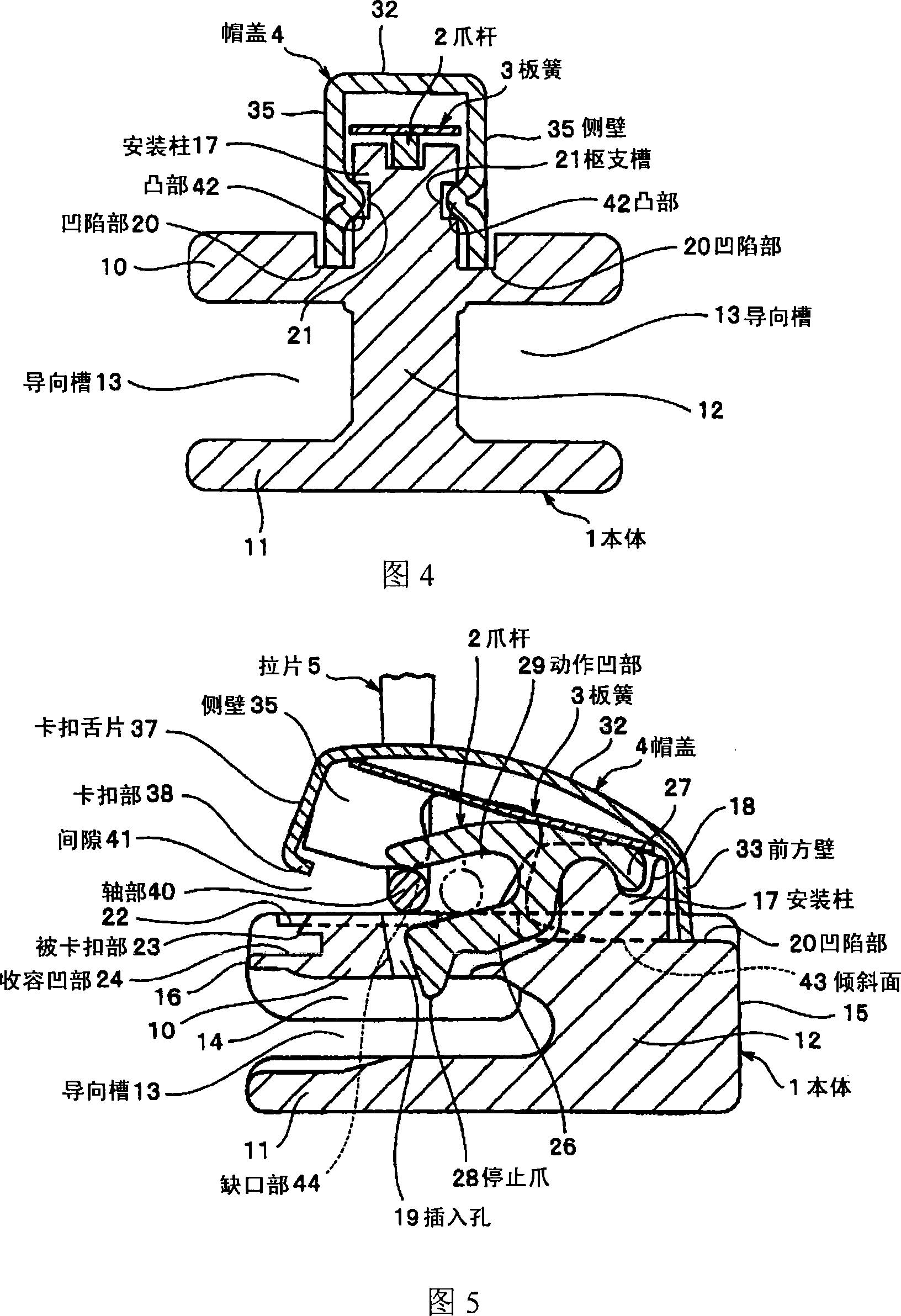

[0044] As mentioned above, the slide fastener puller for a slide fastener with an automatic stop device installed after the handle of the present invention, as shown in FIG. These five components of the pull tab 5 that are installed after the installation are completed. The main body 1 is formed by die-casting zinc alloy or aluminum alloy, and the upper wing plate 10 and the lower wing plate 11, which are arranged up and down oppositely, are connected by the guide column 12, and the opposite sides are formed along the left and right sides of the upper wing plate 10 and the lower wing plate 11. The protruding flanges 14 of the upper and lower wing plates 10, 11 form guide grooves 13 that guide the zipper teeth in the space enclosed by the upper wing plate 10 and the lower wing plate 11, the guide post 12 and the flange 14. On the shoulder 15 side of the upper surface of the upper wing plate 10, that is, the position above the guide column 12 is erected with the mounting column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com