Internal hand-held electric polishing tool with air sac polishing head

A polishing tool and airbag polishing technology, applied in surface polishing machine tools, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of low material removal rate, unstable polishing area, large processing area, etc. Stable, low processing cost and small processing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

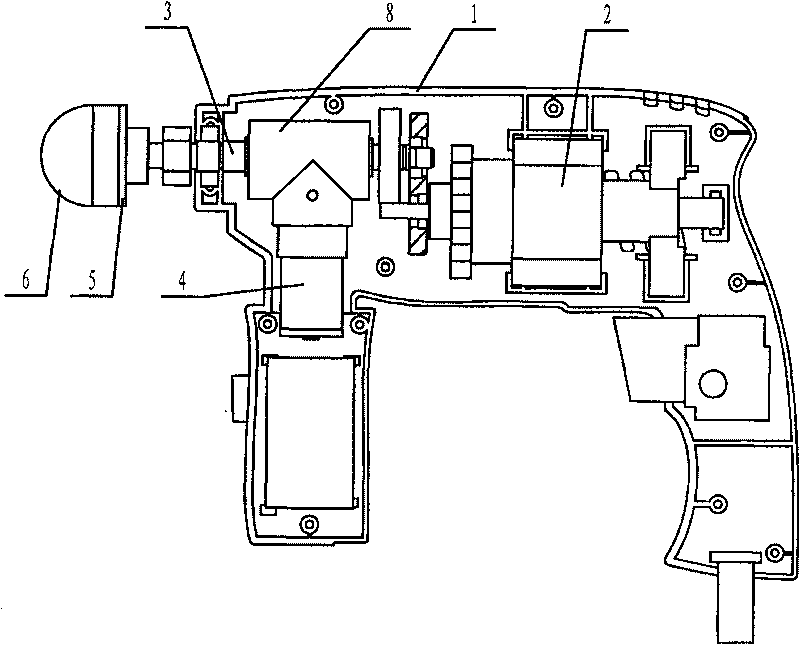

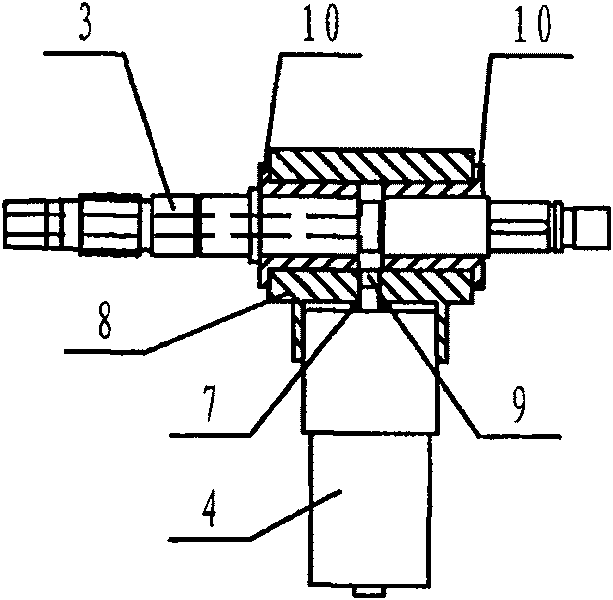

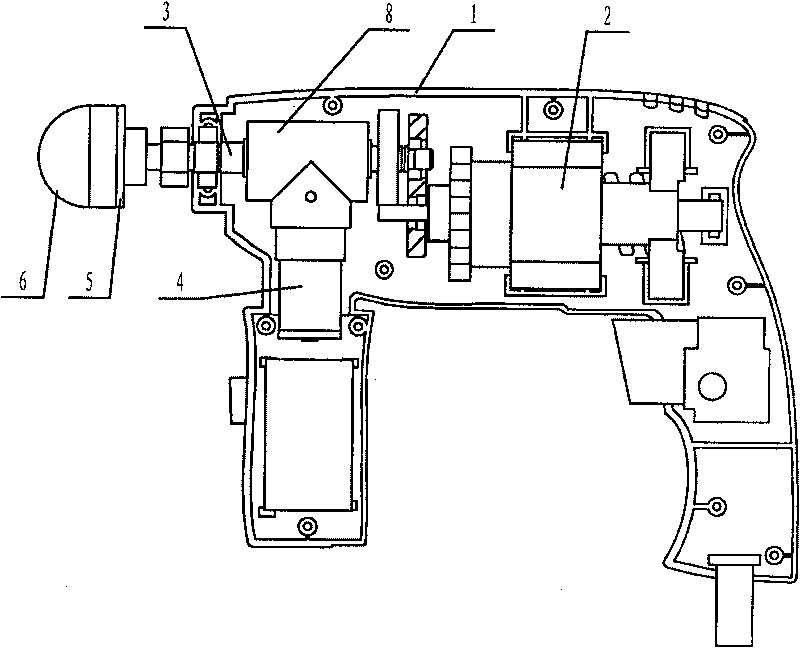

[0021] refer to figure 1 with figure 2 , a built-in hand-held electric polishing tool with an airbag polishing head, including a housing 1 and a driving motor 2, the driving motor 2 is installed in the housing 1, and the hand-held electric polishing tool also includes a polishing head with an airbag head, gas transmission shaft 3 and micro air pump 4, said micro air pump 4 is installed in the shell 1, said polishing head with air bag comprises polishing head skeleton 5 and air bag cover 6, and said air bag cover 6 is sealed and installed on the polishing head One end of the skeleton 5, the polishing head skeleton 5 is a hollow structure; the gas transmission shaft 3 is a semi-hollow shaft, the hollow end of the gas transmission shaft 3 is connected with the other end of the polishing head skeleton 5, and the gas transmission shaft The solid end of 3 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com