Tubular level position precision measuring method based on image processing

A tube level and accuracy measurement technology, applied in the field of image processing, can solve problems such as incorrect calculation results, multiple judgment conditions, misjudgment of bubble contours, etc., and achieve fast and accurate calculation, fast detection speed, and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

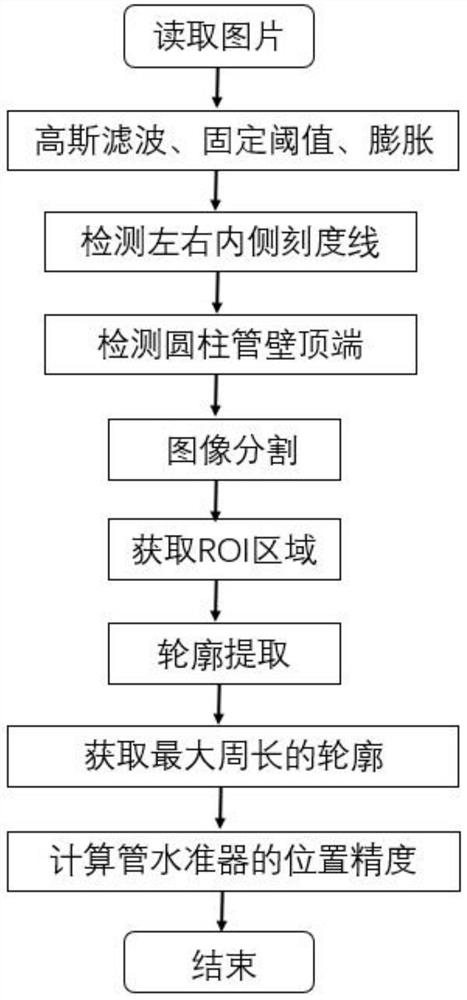

[0033] In this example, see figure 1 , a method for measuring the position accuracy of a tube level based on image processing, which is implemented according to the following steps:

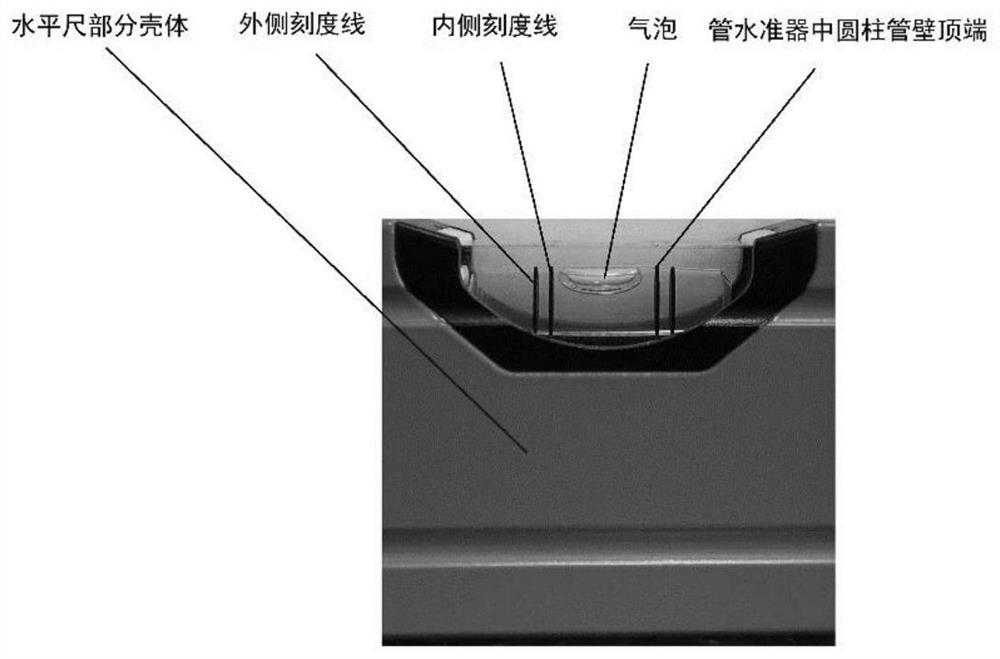

[0034] Step 1: Perform median filtering, fixed threshold and expansion processing on the original image captured by the camera, and find the pixel coordinate P of the right column of the left inner scale line on the tube level by means of pixel traversal l1 and the pixel coordinates P of the left column of the right inner tick mark r1 and the column pixel coordinate P of the middle point of the line width of the inner left tick mark CL and the column pixel coordinates P of the middle point of the line width of the inner right tick mark CR ;

[0035] Step 2: Find the row pixel coordinate value P of the top of the cylinder wall in the vial t ;

[0036] Step 3: Based on the pixel coordinates P of the right column of the left inner tick mark detected in the step 1 l1 and the pixel coordinates P...

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, especially in that:

[0042] In this embodiment, the method for measuring the position accuracy of a tube vial based on image processing in Embodiment 1 is used to detect the product or component of the position accuracy of the level bar and the tube vial assembly through bubble reaction.

[0043] In this embodiment, the position accuracy of the detected product or component in the first embodiment of the method for measuring the position accuracy of a tube level based on image processing includes at least one of horizontal accuracy, vertical accuracy, 45-degree position accuracy, and position accuracy at any angle kind.

[0044] The method in this embodiment can detect horizontal accuracy, vertical accuracy, 45-degree position accuracy, and position accuracy at any angle, and can be used to detect products or components whose position accuracy is reflected by the level ruler and tube vial assembly through air bubbl...

Embodiment 3

[0046]This embodiment is basically the same as the previous embodiment, and the special features are:

[0047] In this example, if figure 1 As shown, the steps of the method for measuring the position accuracy of the tube level based on image processing are:

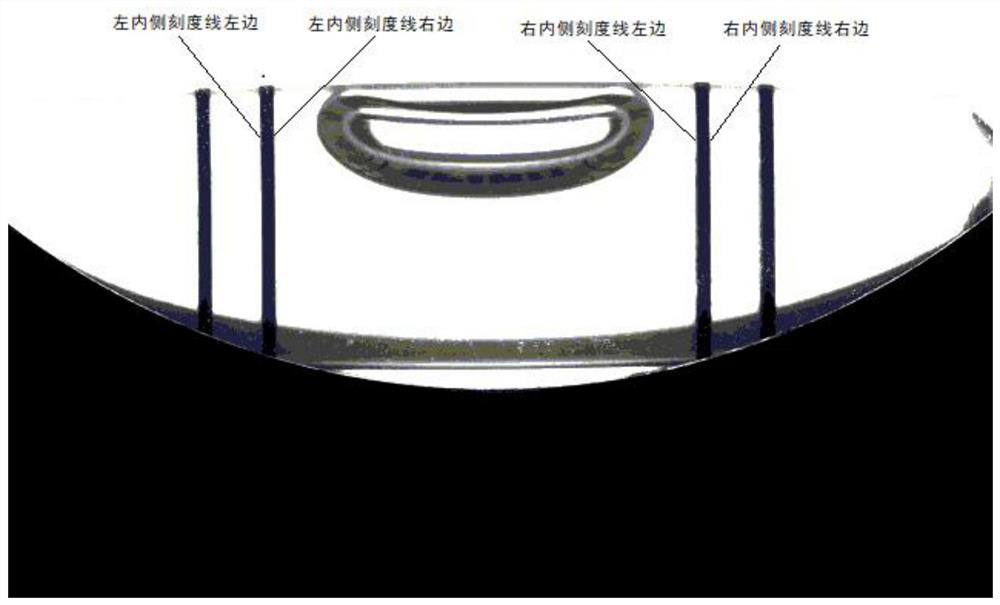

[0048] Step 1: Perform median filtering, fixed threshold and expansion processing on the original image captured by the camera, and find the pixel coordinate P of the right column of the left inner scale line on the tube level by means of pixel traversal l1 and the pixel coordinates P of the left column of the right inner tick mark r1 and the column pixel coordinate P of the middle point of the line width of the inner left tick mark CL and the column pixel coordinates P of the middle point of the line width of the inner right tick mark CR ;Such as image 3 marked as shown;

[0049] Perform median filtering on the original image (Src) to remove noise in the image, such as image 3 As shown, then perform a threshold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com