Vehicle seat back with active head restraint

A technology of headrest and lock mechanism, applied in special positions of vehicles, vehicle seats, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

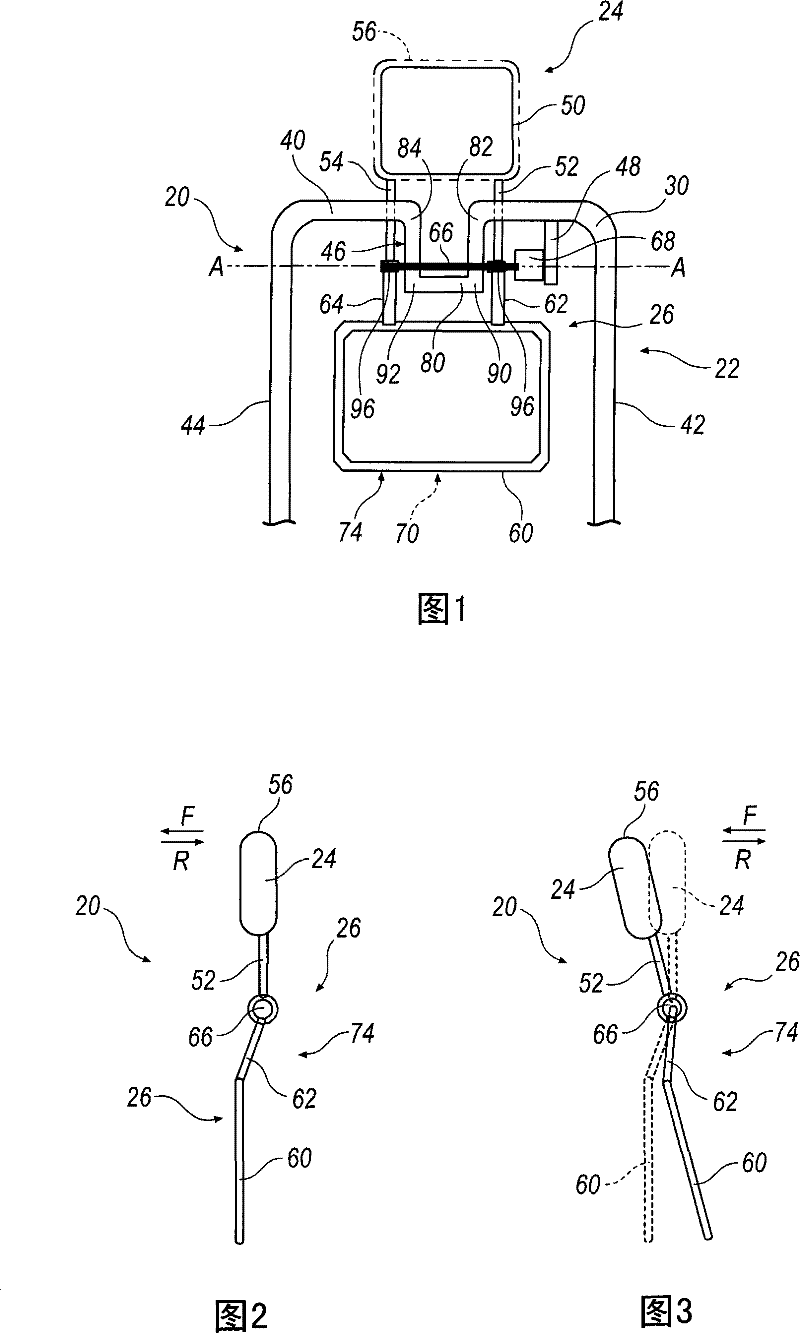

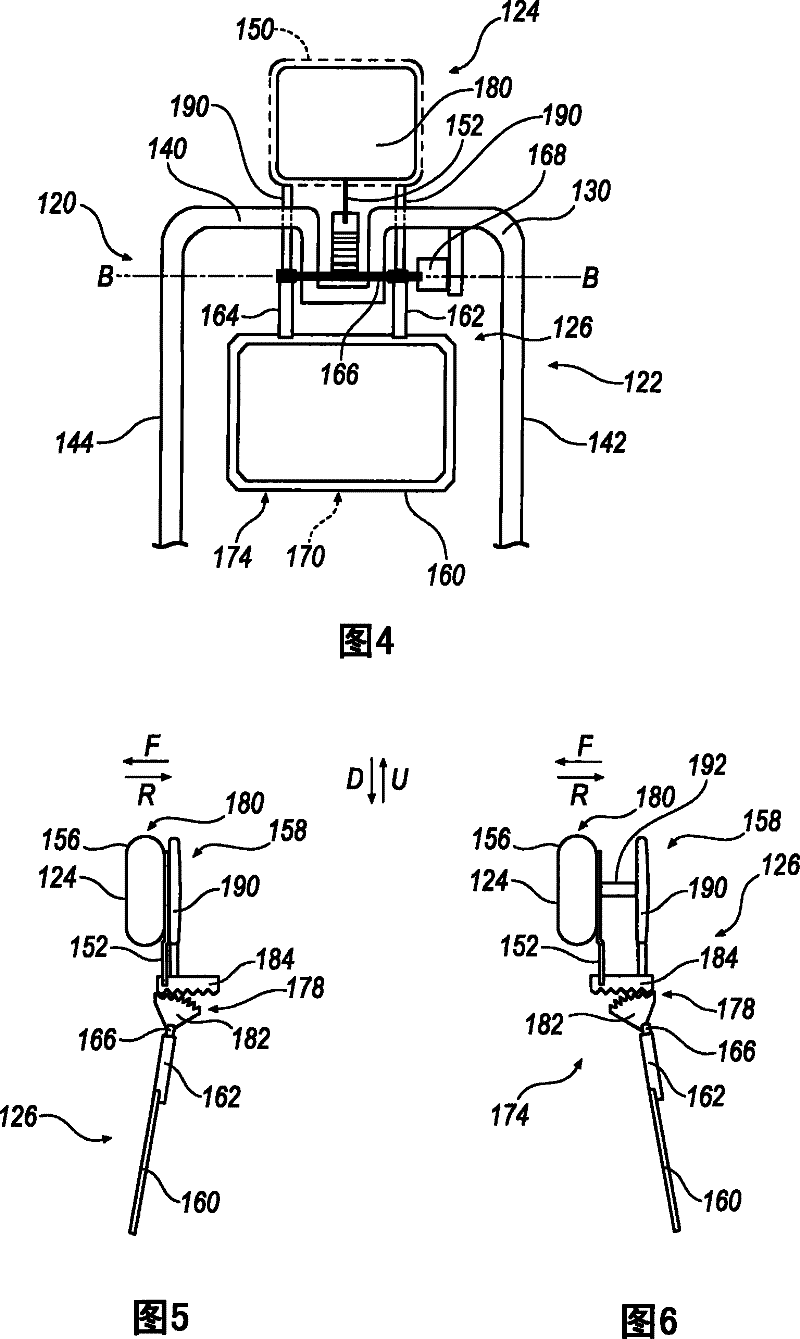

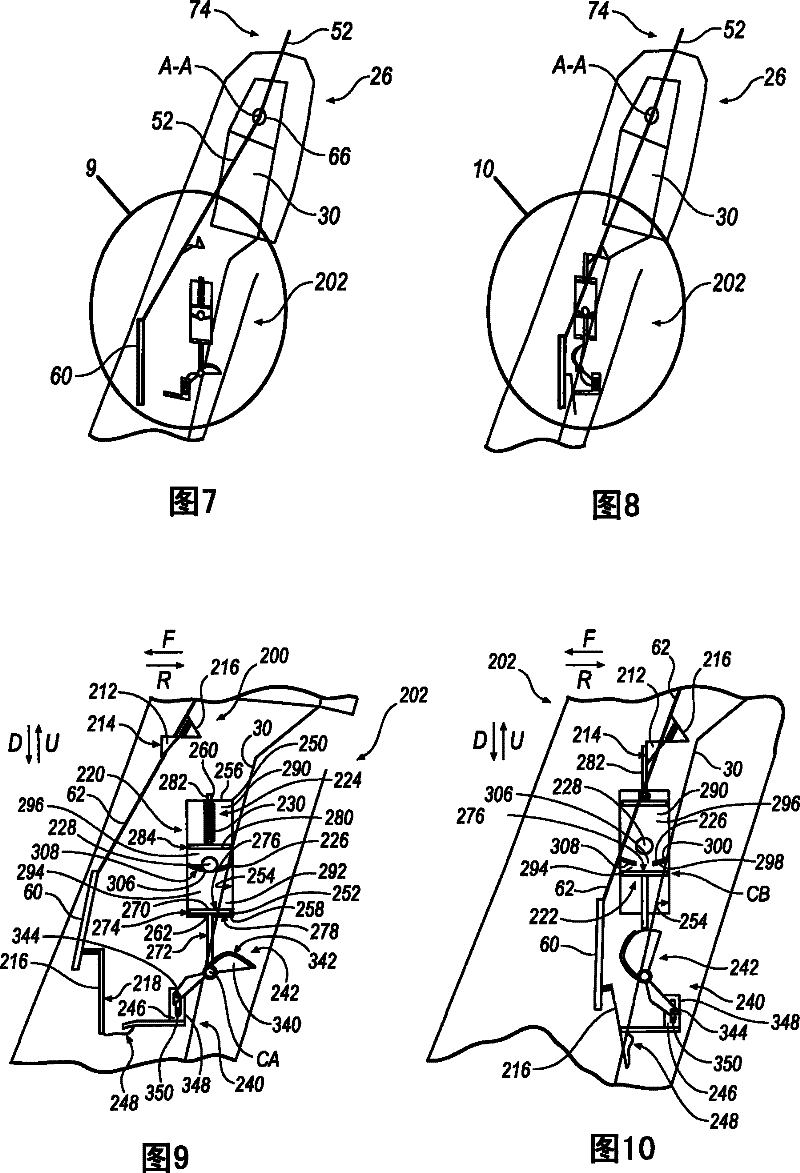

[0029] Figure 1-Figure 3 An active head restraint system 20 is shown. System 20 includes seat back 22 , head restraint 24 , and head restraint control system 26 . The seat back 22 includes a seat back frame 30 attached to a seat bottom (not shown), and a seat back outer cover (not shown). The seat back frame 30 includes a horizontal member 40 , a first vertical member 42 , a second vertical member 44 , a headrest connection portion 46 , and a speed reducer connection portion 48 . The headrest 24 includes a structural portion 50 , a first link 52 , a second link 54 , and a headrest outer cover 56 .

[0030] The head restraint control system 26 includes a chest full member or back plate 60, a first back plate link 62, a second back plate link 64, an interconnect 66 having an axis A-A, a rotational damper or deceleration device 68, and Latch or lock mechanism 70 . In the illustrated embodiment, the head restraint control system 26 is located within an outer seat back cover o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com