Ozone generator with modular structural discharging unit

A technology of ozone generator and discharge module, which is applied in the direction of ozone preparation, etc., can solve the problems that the output of ozone equipment cannot be adjusted according to actual needs, it is not easy to produce, install and maintain, and it takes a lot of time, so as to shorten machine downtime and reduce Maintenance work and labor cost, effect of increasing ozone production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention will be specifically described below in conjunction with the accompanying drawings.

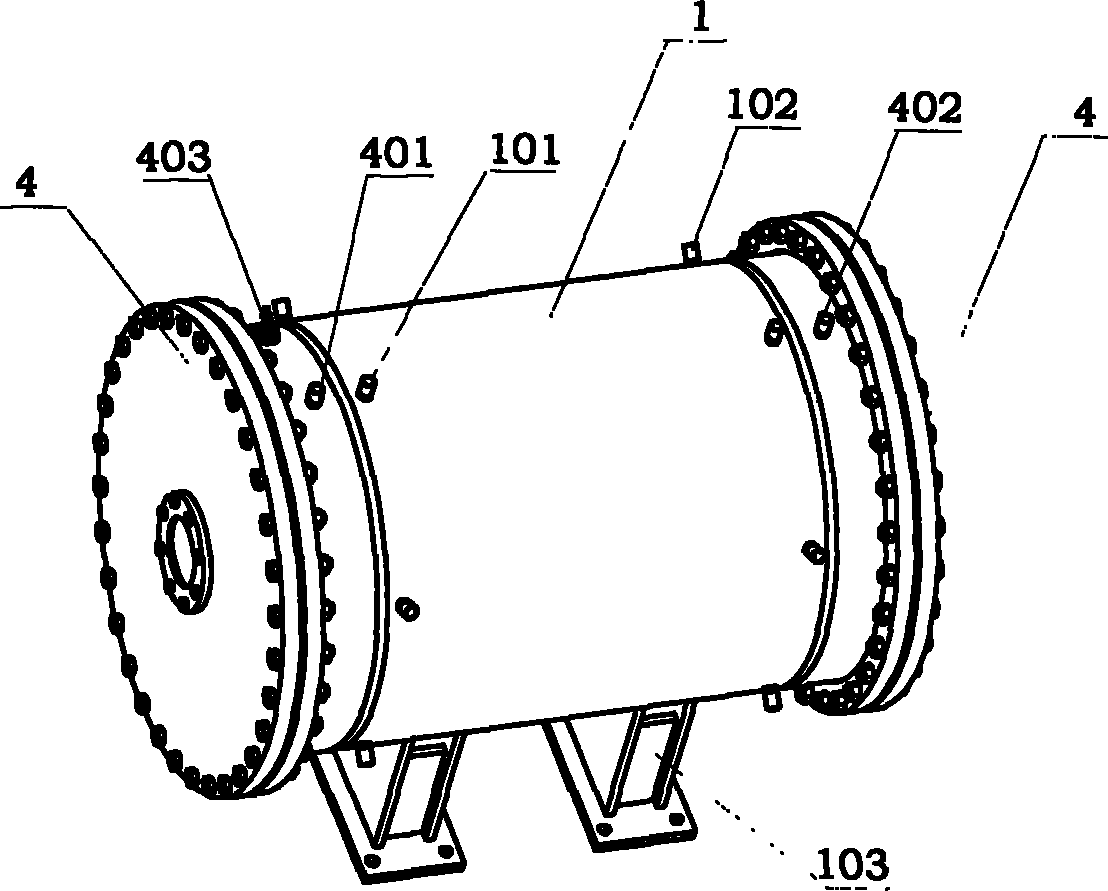

[0025] Such as Figure 1~5 Shown is an embodiment of the ozone generator with the modular structure of the discharge unit of the present invention.

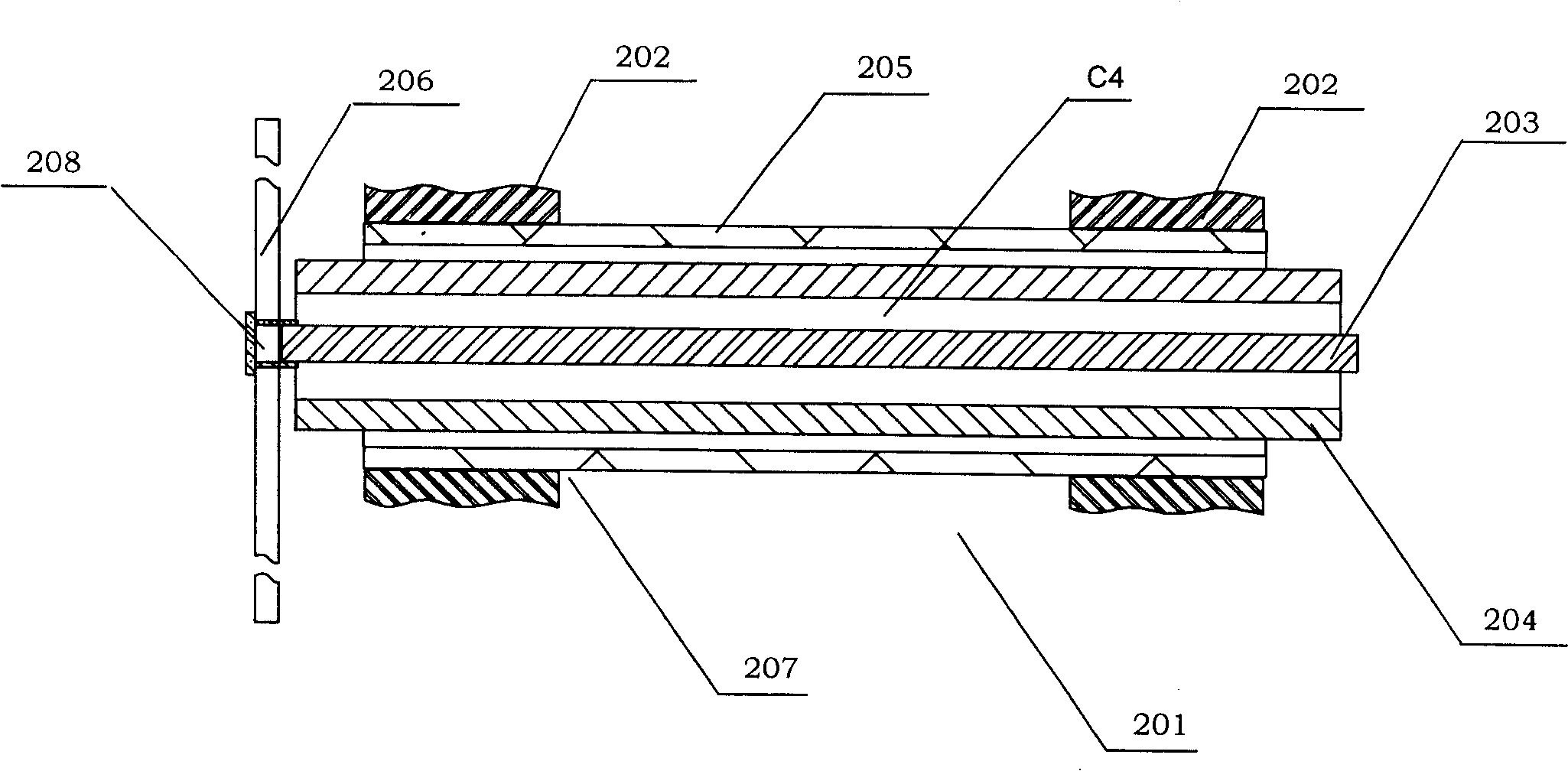

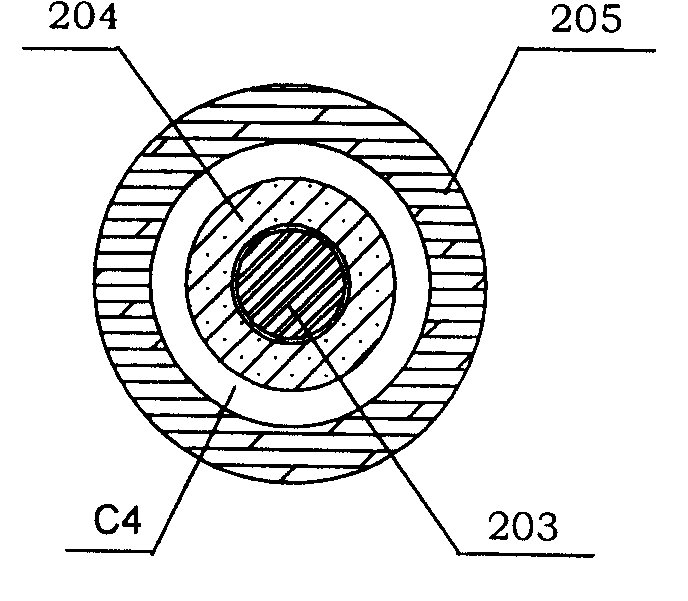

[0026] In this embodiment, the ozone generator includes a discharge chamber C1, an oxygen chamber C2 at both ends of the discharge chamber C1, and an ozone chamber C3. The discharge chamber C1 includes at least one discharge module 2 and two discharge module fixing plates 3 for fixing the discharge module, and the outside of the two discharge module fixing plates 3 are sealed by respective end caps 4 to form two cavities C2 and C3 They are used as oxygen chamber and ozone chamber respectively. The discharge chamber C1 is sealed by the outer wall to form a closed cavity as the cooling cavity 1 , and the corresponding positions of the two discharge module fixing plates 3 have several pairs of through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com