A kind of ceramic coating composition and its preparation method and application

A technology for ceramic coating and composition, applied in the field of ceramic coating composition and preparation thereof, can solve the problems of poor electrical conductivity, poor resistance to ozone corrosion, insufficient resistance to ozone corrosion, etc. The effect of energy consumption, strong acid and alkali resistance and ozone corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

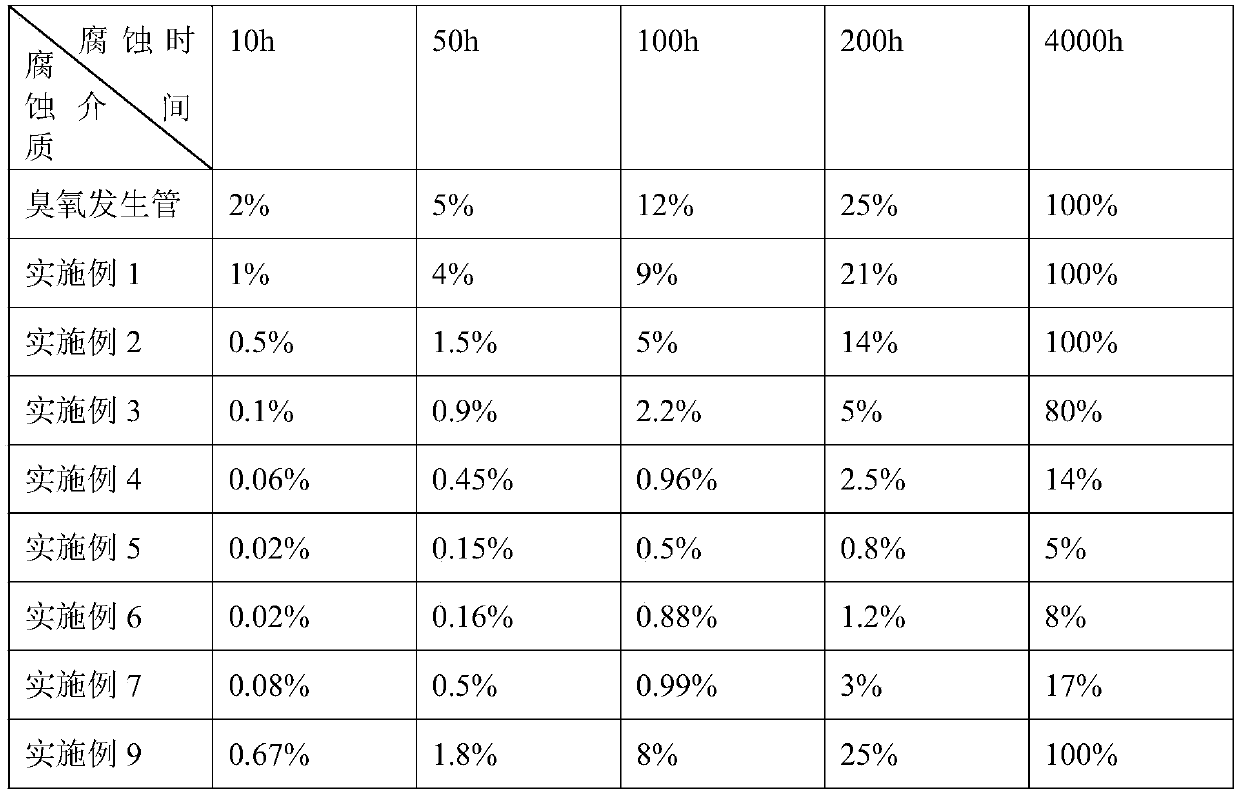

Examples

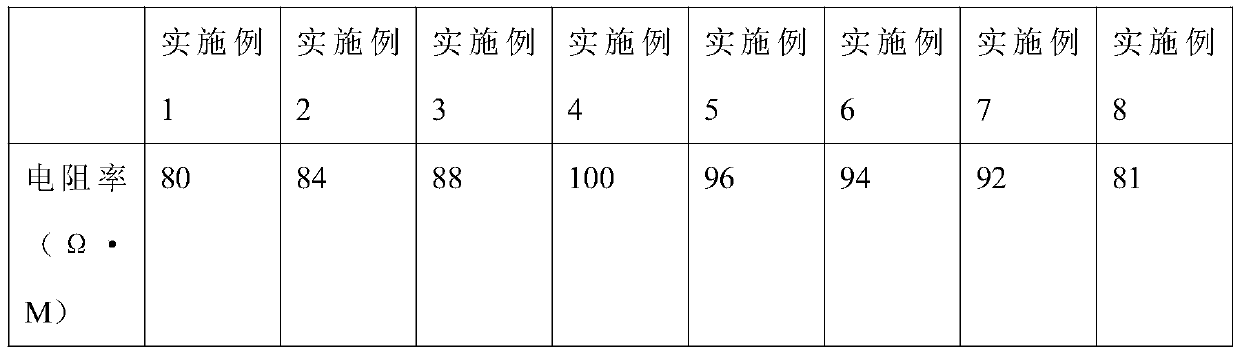

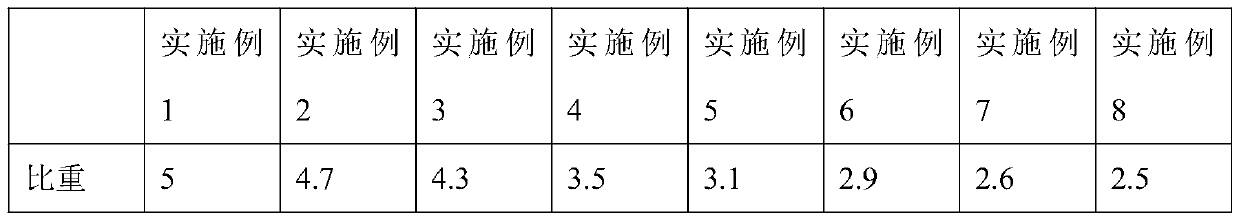

Embodiment 1

[0039] A ceramic coating composition, comprising the following components by weight percentage:

[0040] Titanium trioxide 54%;

[0041] Zirconia 36%;

[0042] Magnesium oxide 4%;

[0043] Sodium sulfate 2%;

[0044] Zinc Oxide 4%.

[0045] Wherein the α-crystalline titanium dioxide, zirconia and sodium sulfate are all 0.5 μm powders, and the magnesium oxide and zinc oxide are all 0.2 μm powders. The preparation method of the above-mentioned ceramic coating composition, it comprises the following steps: according to the above-mentioned formula ratio, weigh titanium dioxide, zirconium oxide, magnesium oxide, sodium sulfate and zinc oxide respectively, put into the mixer (rotating speed is 900rpm, stirring time is 10 minute), mix uniformly to obtain the ceramic coating composition.

[0046] The application of the above-mentioned ceramic coating composition for preventing the corrosion of the ozone generating pipe comprises the following steps:

[0047] 1) Clean the surface...

Embodiment 2

[0052] A ceramic coating composition, comprising the following components by weight percentage:

[0053] Titanium trioxide 63%;

[0054] Zirconia 27%;

[0055] Magnesium oxide 3%;

[0056] Sodium sulfate 2%;

[0057] Zinc Oxide 5%.

[0058]Wherein the α-crystalline titanium dioxide, zirconia and sodium sulfate are all 0.5 μm powders, and the magnesium oxide and zinc oxide are all 0.2 μm powders.

[0059] The preparation method of the above-mentioned ceramic coating comprises the following steps: respectively weigh titania, zirconia, magnesium oxide, sodium sulfate and zinc oxide according to the above-mentioned formula ratio, and put them into a mixer (rotating speed is 300rpm, stirring time is 60 minutes) and mix uniformly to obtain the ceramic coating composition. The application of the above-mentioned ceramic coating composition for preventing the corrosion of the ozone generating pipe comprises the following steps:

[0060] 1) Clean the surface of the ozone generatin...

Embodiment 3

[0065] A ceramic coating composition, comprising the following components by weight percentage:

[0066] Titanium trioxide 72%;

[0067] Zirconia 18%;

[0068] Magnesium oxide 2%;

[0069] Sodium sulfate 1%;

[0070] Zinc Oxide 7%.

[0071] The preparation method of the above-mentioned ceramic coating composition comprises the following steps: respectively weigh titanium dioxide, zirconium oxide, magnesium oxide, sodium sulfate and zinc oxide according to the above-mentioned formula ratio, and put them into a mixer (the rotating speed is 1500rpm, and the stirring time is 12 minutes) ), mix uniformly to obtain the ceramic coating composition.

[0072] The application of the above-mentioned ceramic coating composition for preventing the corrosion of the ozone generating pipe comprises the following steps:

[0073] 1) Clean the surface of the ozone generating tube with ultrasonic waves (the power density configured by capacity is 11W / L, and the frequency is 75KHz), and use a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com