Spiral cylindric discharging unit for ozone generator

An ozone generator and discharge unit technology, applied in the field of ozone generators, can solve the problems of small discharge specific surface area of ozone generators, high installation and maintenance costs, increased floor space, etc., to reduce equipment investment and maintenance costs, easy to use. Maintenance and space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

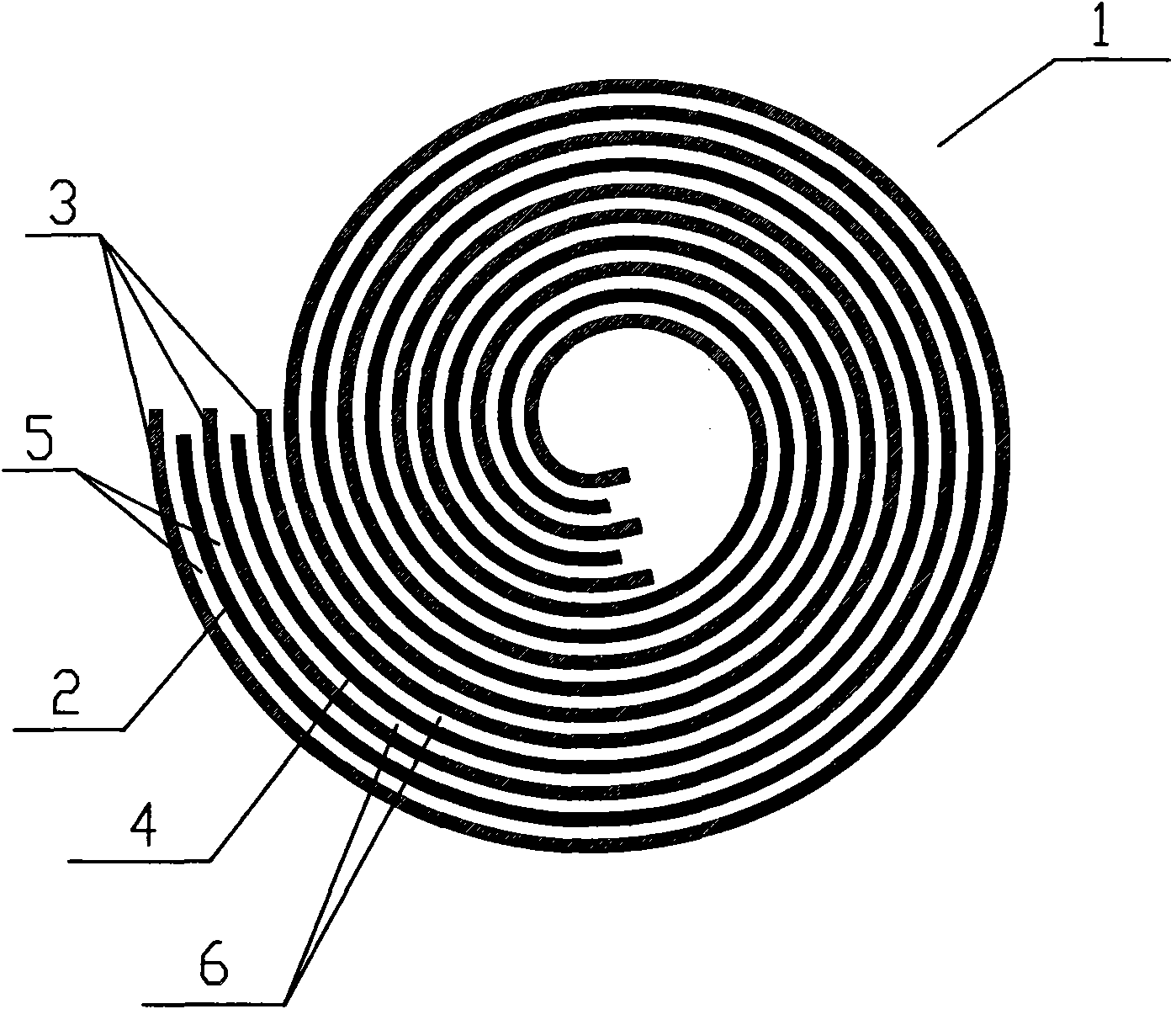

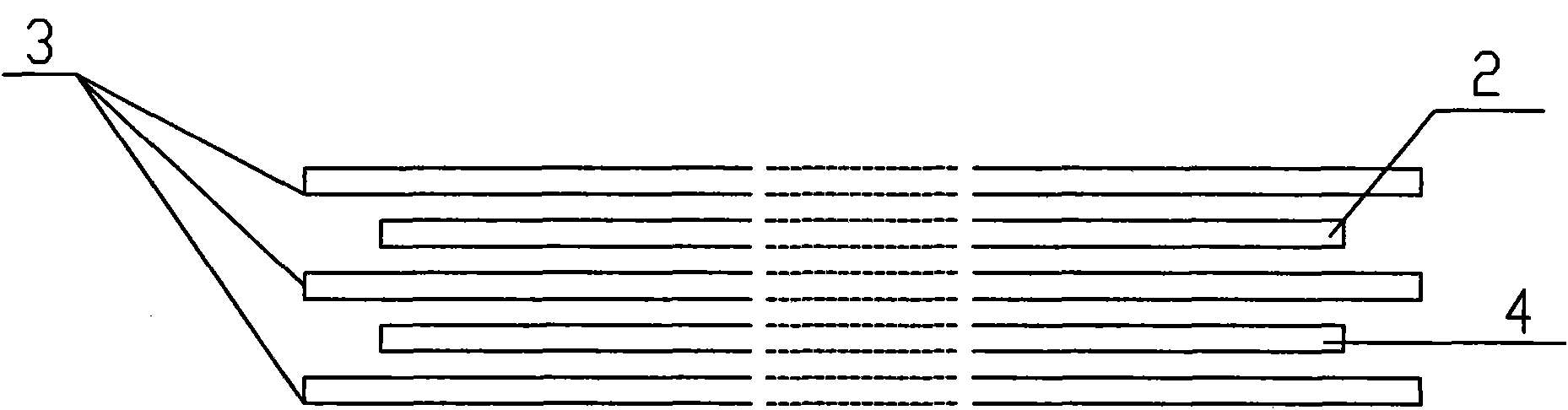

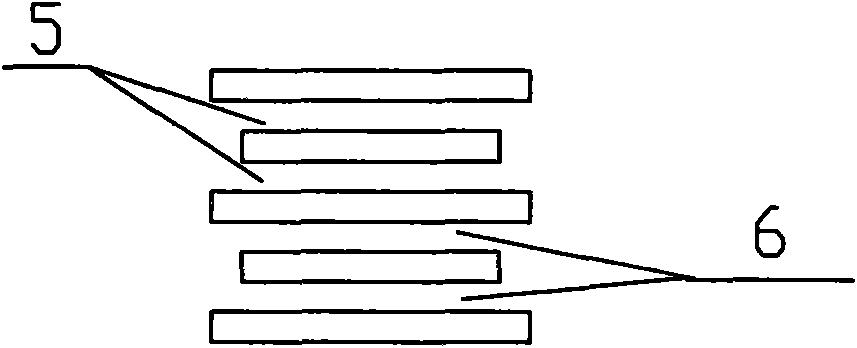

[0029] Such as Figure 1-3 As shown, the spiral cylindrical discharge unit 1 for the ozone generator is composed of a group of film-shaped and rollable ground electrodes 2, insulating layers 3 and high-voltage electrodes 4, and the number is not less than one. One edge is wound into several turns of a spiral cylinder, in which the high-voltage electrode 4 and the ground electrode 2 are separated by the insulating layer 3, and there are gaps between the ground electrode 2 and the insulating layer 3, and between the insulating layer 3 and the high-voltage electrode 4 5 and 6. The spiral cylindrical discharge unit 1 in this embodiment is formed by stacking one layer of ground electrode 2 , three layers of insulating layers 3 and one layer of high voltage electrode 4 . The edge of the insulating layer 3 protrudes beyond the ground electrode 2 and the high voltage electrode 4 . The sizes of the gaps 5 and 6 are between 0.05mm and 0.4mm respectively.

Embodiment 2

[0031] Such as Figure 4 As shown, different from Embodiment 1, in Embodiment 2, the spiral cylindrical discharge cell also includes an axis 7, and the stacked ground electrode 2, insulating layer 3 and high voltage electrode 4 take the axis 7 as the axis 7. The center is wound around the axis 7 as a whole to form a spiral cylinder. The shaft 7 is in the shape of a hollow tube. In practical applications, water or other cooling media can be passed through the tube to achieve good heat dissipation. It is also possible to electrically connect the shaft to the high voltage electrodes.

[0032] In order to facilitate identification, the number of helical turns of the helical cylindrical discharge unit shown in the schematic diagram of the embodiment of this specification is relatively small, which can be increased as required in practical applications. In the figure, there is one high-voltage electrode and one ground electrode, and three insulating layers. In practical applicatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com